Manufacturing environments require tools and components that are durable, efficient, and cost-effective.

Tungsten carbide tips are widely used in manufacturing due to their exceptional độ cứng, khả năng chống mài mòn, and long lifespan.

While tungsten carbide tips may have a higher initial cost compared to other materials, their ability to reduce maintenance costs can make them a more economical choice over time.

In this article, we’ll explore how tungsten carbide tips help reduce maintenance costs in manufacturing and why they are a smart investment for businesses looking to increase productivity and lower overall costs.

Why Maintenance Costs Matter in Manufacturing

In manufacturing, maintenance is an essential part of keeping operations running smoothly.

However, frequent maintenance can lead to significant costs, including labor, downtime, and the cost of spare parts. These expenses can add up over time, affecting the overall profitability of the operation.

One of the biggest contributors to maintenance costs is the frequent replacement of tools and components that wear out quickly.

This is where tungsten carbide tips come into play. Known for their durability and khả năng chống mài mòn, tungsten carbide tips can significantly reduce the need for frequent tool replacements, thereby lowering maintenance costs.

How Tungsten Carbide Tips Reduce Maintenance Costs

1). Extended Tool Life

Tungsten carbide tips are incredibly durable and resistant to wear, meaning they last much longer than other materials, such as high-speed steel (HSS) or standard carbide.

By using tungsten carbide tips, manufacturers can avoid the frequent replacement of tools, reducing both the costs and downtime associated with tool changes.

Example:

A tungsten carbide tip used in cutting operations can last several times longer than an HSS tool, reducing the need for replacements and ensuring longer production runs without interruptions.

2). Reduced Downtime

Downtime is one of the most significant contributors to maintenance costs in manufacturing.

When tools wear out or break, the machinery must be stopped for maintenance or replacement.

Tungsten carbide tips’ longer lifespan means fewer tool changes, leading to less downtime and increased productivity.

Example:

A manufacturing facility that uses tungsten carbide tips will experience fewer interruptions, allowing production to continue smoothly without the need for frequent tool replacements or adjustments.

3). Lower Frequency of Tool Repairs

Tungsten carbide’s độ dẻo dai and resistance to damage make it less likely to need repairs.

Tools with tungsten carbide tips are better able to withstand high pressures, temperatures, and abrasive forces, reducing the need for costly repairs or servicing.

Example:

Trong các ngành công nghiệp như khai thác mỏ hoặc gia công kim loại, where tools are exposed to abrasive materials, tungsten carbide tips are less likely to break, chip, or become damaged, saving money on repairs.

4). Improved Cutting Performance

Tungsten carbide tips provide superior cutting performance compared to other materials, which means they are more efficient at cutting, grinding, or machining materials.

This efficiency leads to better throughput and reduced wear on both the tools and the machinery itself, lowering maintenance costs over time.

Example:

Tungsten carbide tips can cut more efficiently and with greater precision, reducing the stress on machines and extending their operational life, which minimizes the need for repairs and maintenance.

5). Fewer Tool Changes and Labor Costs

Because tungsten carbide tips last longer and perform better, manufacturers will need to change tools less frequently, saving both time and labor costs.

Fewer tool changes mean that employees can focus on other important tasks, increasing overall productivity.

Example:

A manufacturing line that requires fewer tool changes will reduce labor costs associated with frequent tool replacement, and operators will have more time to focus on improving other parts of the production process.

6). Reduced Material Waste

Tungsten carbide tips provide more precise cuts and work more efficiently, leading to less material waste.

In manufacturing, material waste directly contributes to costs, so minimizing waste can significantly lower overall expenses.

By improving the accuracy of the cutting process, tungsten carbide tips help reduce the amount of raw material wasted during production.

Example:

Tungsten carbide tips in CNC machining can improve the quality of the finished product, reducing the need for rework or scrap materials, which lowers material costs and waste.

How to Maximize the Cost-Saving Benefits of Tungsten Carbide Tips

While tungsten carbide tips offer many benefits, it’s essential to implement proper maintenance practices to maximize their cost-saving potential.

Here are some tips for ensuring the longest lifespan and greatest efficiency from your tungsten carbide tips:

1). Regular Maintenance of Equipment

Although tungsten carbide tips are durable, it’s still important to maintain the equipment they are used with.

Regular cleaning, lubrication, and inspection of machinery can help ensure that both the tips and the equipment remain in good working condition.

2). Proper Tool Setup

Ensure that the tungsten carbide tips are installed correctly to avoid issues like misalignment, which can lead to premature wear or damage.

Proper tool setup reduces the chances of unnecessary wear and extends the life of the tips.

3). Monitor Tool Performance

Keep track of the performance of your tungsten carbide tips, including any signs of wear or damage.

Regular monitoring allows you to replace tips at the optimal time, avoiding both premature replacements and unnecessary downtime.

Key Considerations When Choosing Tungsten Carbide Tips

While tungsten carbide tips offer significant cost-saving advantages, it’s important to choose the right type of tip for your specific manufacturing needs. Here are some factors to consider:

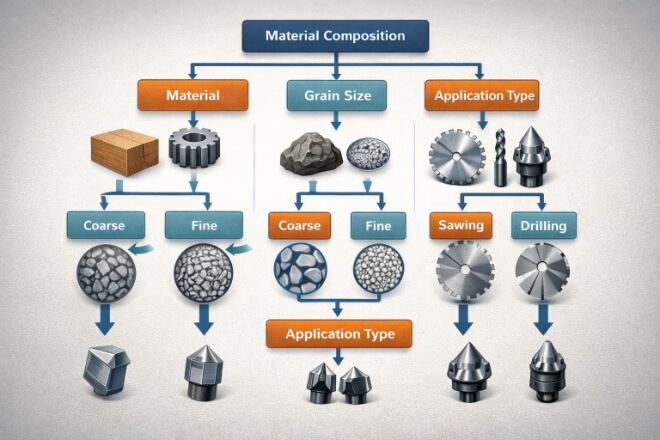

1). Material Composition

Tungsten carbide tips are made with different binder materials, such as cobalt or nickel.

The binder type can affect the tip’s khả năng chống mài mòn, độ dẻo dai, Và khả năng chống ăn mòn.

Choose the right binder material based on your application’s needs.

2). Kích thước hạt

The grain size of tungsten carbide can influence its hardness and wear resistance.

Fine-grain tungsten carbide offers better wear resistance, while coarse-grain carbide is better for applications that require toughness.

Consider the specific requirements of your manufacturing process when selecting grain size.

3). Application Type

Different applications may require different types of tungsten carbide tips.

For example, tips used in cutting applications may have different properties than those used in grinding or drilling.

Be sure to choose the right tip for your specific application to maximize performance and reduce maintenance costs.

Phần kết luận

Tungsten carbide tips offer substantial cost-saving benefits for manufacturers by extending tool life, reducing downtime, and lowering maintenance costs.

By selecting the right tungsten carbide tips and following proper maintenance practices, manufacturers can improve efficiency, reduce waste, and maximize the return on investment.

Investing in tungsten carbide tips is not just about higher initial costs; it’s about long-term savings and improved productivity.

By reducing the frequency of tool changes, repairs, and maintenance, tungsten carbide tips can significantly lower the total cost of ownership and improve the bottom line.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.