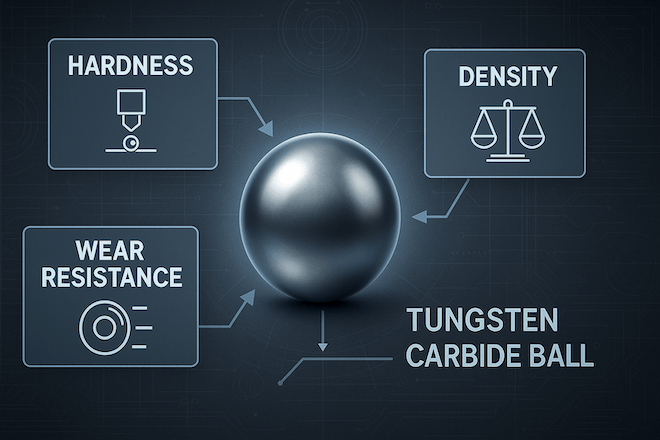

Bóng cacbua vonfram are known for their exceptional performance in many industries. They are used in bearings, valves, measuring tools, oil & gas equipment, and even pens. Their popularity comes from three main properties: hardness, density, and wear resistance.

In this guide, we will explain each property in simple terms, show why it matters, and help you understand why tungsten carbide balls are often the best choice.

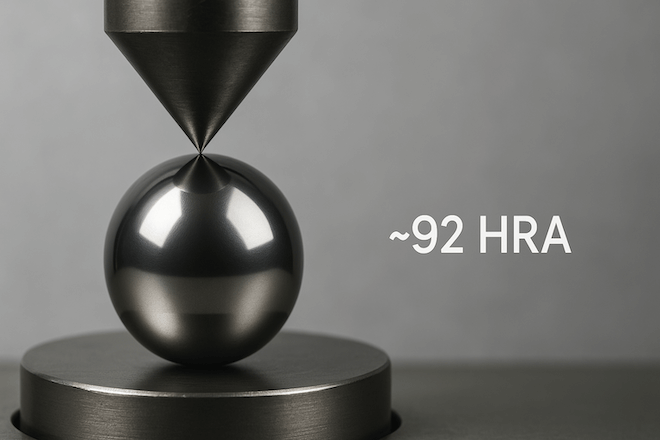

Hardness of Tungsten Carbide Balls

Độ cứng is the ability of a material to resist scratching, cutting, or deformation. Tungsten carbide balls have a hardness of about 89–94 HRA, which is much harder than steel and close to diamond on the hardness scale.

Tại sao độ cứng lại quan trọng:

The ball keeps its shape under high load.

It resists surface damage in rough environments.

It lasts longer in applications with high contact pressure.

Example:

In a precision bearing, a steel ball may deform slightly over time, while a tungsten carbide ball will stay perfectly round for much longer.

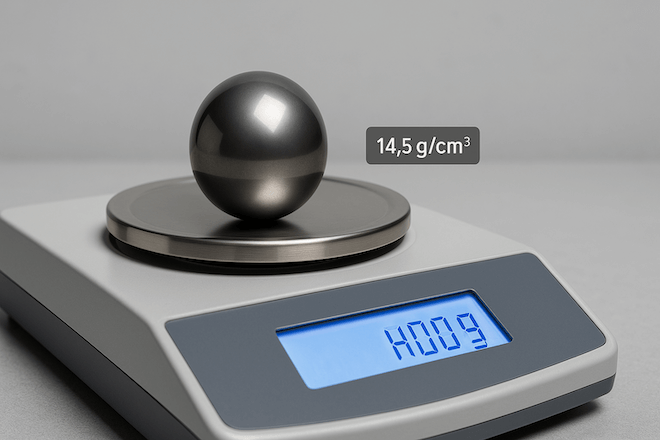

Density of Tungsten Carbide Balls

Tỉ trọng means how heavy a material is for its size. Tungsten carbide balls have a density of about 14.5 g/cm³, which is more than twice the density of steel.

Why density matters:

The ball has more mass, which can be important in balancing rotating parts.

Heavier balls are more stable in moving machinery.

In measurement devices, higher density can reduce vibration.

Example:

In a gyroscope used in aerospace navigation, a high-density tungsten carbide ball provides smoother and more stable rotation.

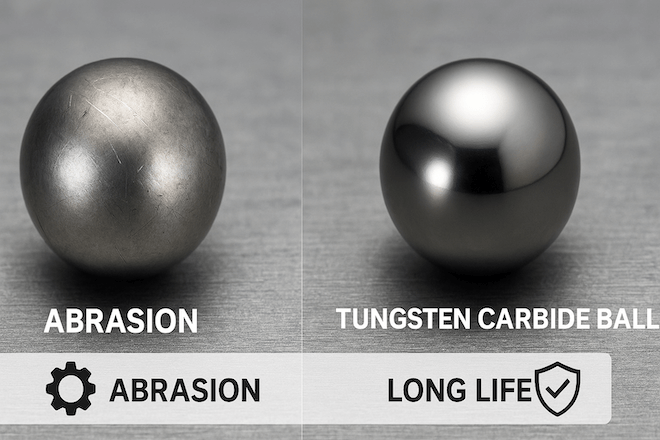

Wear Resistance of Tungsten Carbide Balls

Khả năng chống mài mòn is the ability to resist surface damage from friction, abrasion, or contact with other materials. Tungsten carbide balls perform extremely well here because their hardness and toughness work together.

Why wear resistance matters:

The ball stays smooth even after long use.

Reduced wear means longer service life.

Machines work more efficiently with less downtime.

Example:

In an oil & gas valve, tungsten carbide balls maintain a tight seal even after years of contact with abrasive fluids.

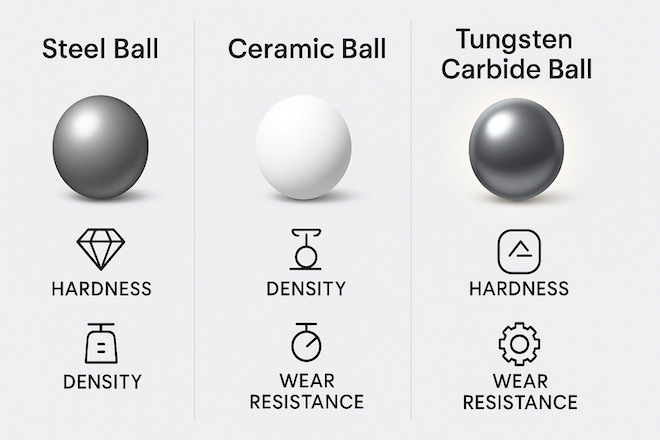

Comparison Table: Tungsten Carbide vs Steel vs Ceramic

| Tài sản | Tungsten Carbide Ball | Steel Ball | Ceramic Ball |

|---|---|---|---|

| Độ cứng | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Tỉ trọng | ★★★★★ | ★★★☆☆ | ★★☆☆☆ |

| Khả năng chống mài mòn | ★★★★★ | ★★★☆☆ | ★★★★☆ |

| Trị giá | Cao hơn | Thấp | Trung bình |

| Service Life | Very Long | Trung bình | Medium to Long |

How These Properties Work Together

The combination of high hardness, high density, and excellent wear resistance makes tungsten carbide balls ideal for:

High-load bearings (they won’t deform under stress)

Precision measuring tools (they keep exact dimensions)

Abrasive environments (like oil & gas, mining, or chemical processing)

High-speed applications (they maintain balance and stability)

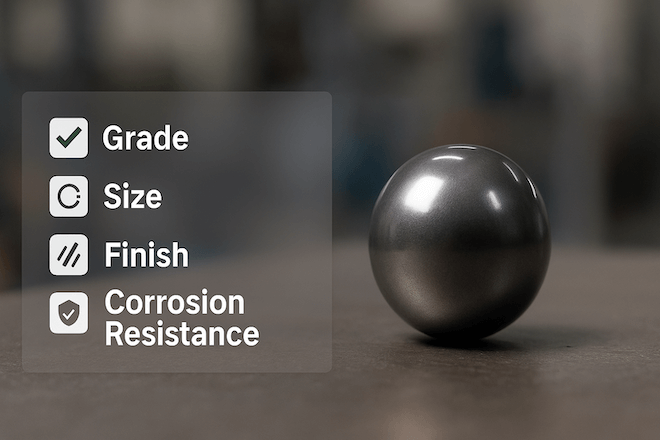

Selecting Tungsten Carbide Balls for Your Application

When choosing tungsten carbide balls, you should check:

Cấp and hardness – Choose the right hardness for your application.

Size and tolerance – Precision is key in high-performance machinery.

Surface finish – Polished balls work better in precision tools.

Khả năng chống ăn mòn needs – Some grades are better in chemical environments.

Suy nghĩ cuối cùng

Tungsten carbide balls stand out because of their hardness, density, and wear resistance. These properties give them long service life, high stability, and excellent performance in demanding applications.

If your project needs a ball that will stay precise and last for years, tungsten carbide balls are one of the best investments you can make.

At Retop, we offer custom sizes, grades, and tolerances for tungsten carbide balls. Whether you need them for industrial machinery, precision measuring devices, or harsh chemical environments, we can provide a solution that works.