Tungsten carbide tips are widely used in various cutting tools due to their exceptional properties.

These tips are preferred in industries like metalworking, khai thác mỏ, and construction because of their superior performance compared to traditional materials like steel.

In this blog, we will explore the key properties of tungsten carbide that make it the ideal choice for cutting tools, and how these properties enhance productivity, tool life, and overall performance.

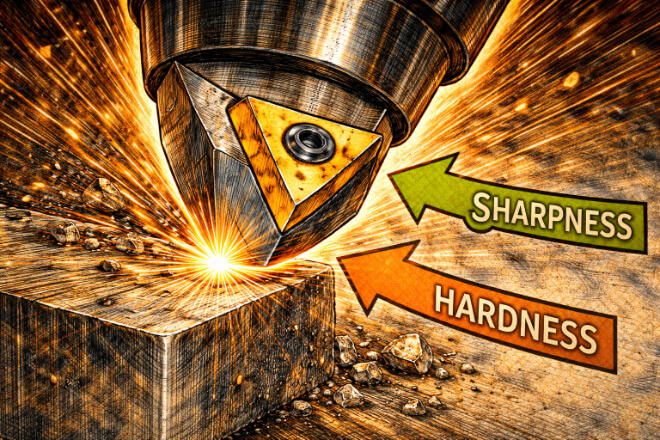

Hardness and Durability: The Backbone of Tungsten Carbide Tips

One of the main reasons why tungsten carbide tips stand out in cutting tools is their extreme hardness and durability.

Tungsten carbide is one of the hardest materials available, second only to diamond.

This makes it a perfect fit for industries that require tools capable of withstanding high pressure and abrasive environments.

1). Độ cứng and Long-Lasting Performance

Tungsten carbide’s hardness ensures that cutting tools remain sharp and efficient for much longer compared to steel.

Steel, being softer, wears down much faster, especially in tough or abrasive conditions.

Tungsten carbide tips maintain their sharpness and precision over extended periods, reducing the need for frequent replacements.

Wear Resistance: Enhancing Tool Longevity

Tungsten carbide tips are designed to withstand wear and tear, making them perfect for industrial applications where tools are exposed to abrasive materials.

Các khả năng chống mài mòn of tungsten carbide allows tools to last significantly longer than those made with steel.

1). Reducing Maintenance Costs

With tungsten carbide tips, businesses experience less downtime and fewer maintenance requirements.

The superior wear resistance reduces the frequency of tool replacements and helps maintain high productivity in industries like mining, manufacturing, and construction.

High Temperature and Impact Resistance: Ideal for Harsh Conditions

Tungsten carbide is also highly resistant to high temperatures, which is essential for cutting tools used in industries where heat is a concern.

This material also has excellent impact resistance, allowing it to endure sudden shocks and vibrations without losing its integrity.

1). Better Performance in High-Temperature Environments

In high-temperature applications, regular steel tips might lose their strength and become brittle.

Tungsten carbide, however, maintains its performance even under extreme heat, making it ideal for metalworking, automotive, and aerospace industries.

Strength and Precision: Achieving Superior Cutting Results

Tungsten carbide is not only hard and wear-resistant but also provides excellent strength.

This strength allows tungsten carbide tips to maintain cutting precision and provide superior results when working with difficult-to-cut materials.

1). Maintaining Sharpness for Cleaner Cuts

The strength of tungsten carbide ensures that cutting tools remain precise, delivering cleaner and more accurate cuts, which is crucial in industries where precision is key.

Cost-Effectiveness Over Time

While tungsten carbide tips may come with a higher initial cost compared to steel, their long-lasting performance and durability make them a more cost-effective solution in the long run.

Companies experience fewer tool replacements, lower maintenance costs, and reduced downtime, all of which contribute to overall savings.

1). Return on Investment

The longevity of tungsten carbide tips makes them a wise investment.

The extended tool life, increased efficiency, and improved productivity make tungsten carbide tips the more cost-effective option over time, despite their higher upfront cost.

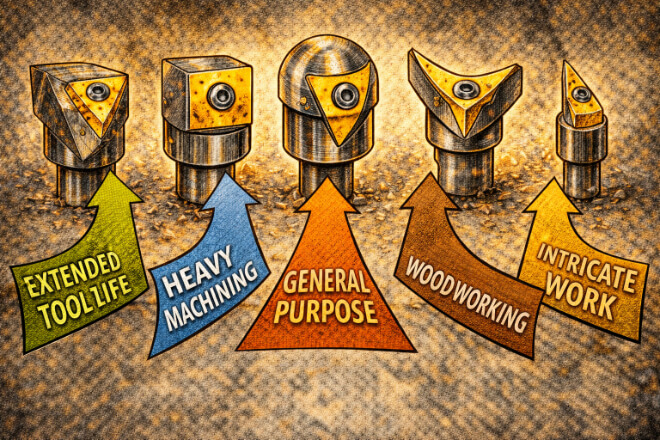

How to Choose the Right Tungsten Carbide Tip for Your Application

When choosing tungsten carbide tips, it is important to consider the specific requirements of your application.

Factors such as material hardness, cutting environment, and required tool precision all play a role in determining the right type of tungsten carbide tip for your needs.

1). Material and Application Compatibility

Different grades and forms of tungsten carbide are available, each suited to different applications.

Be sure to choose the correct grade of tungsten carbide tip based on the material you’re cutting and the specific conditions of your operation.

Phần kết luận

Tungsten carbide tips are unmatched in performance compared to regular steel tips, offering superior hardness, wear resistance, heat resistance, impact resistance, and strength.

These properties make tungsten carbide the ideal material for a wide range of cutting tools used in harsh industrial applications.

While the initial investment in tungsten carbide tips may be higher, their long-lasting performance, reduced downtime, and overall cost-effectiveness make them the smarter choice for businesses that rely on precision and durability in their tools.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.