Ống lót cacbua vonfram are used in high-performance systems such as pumps, compressors, turbines, and rotating equipment.

They are chosen for their độ cứng, khả năng chống mài mòn, and dimensional stability — even under heavy loads and extreme temperatures.

However, their performance heavily depends on two key factors: proper lubrication and effective cooling.

Without them, even the hardest material can fail due to frictional heat, galling, or surface microcracking.

This article explains the best lubrication and cooling practices that help extend the service life of tungsten carbide bushings, improve reliability, and reduce maintenance costs.

Why Lubrication Matters

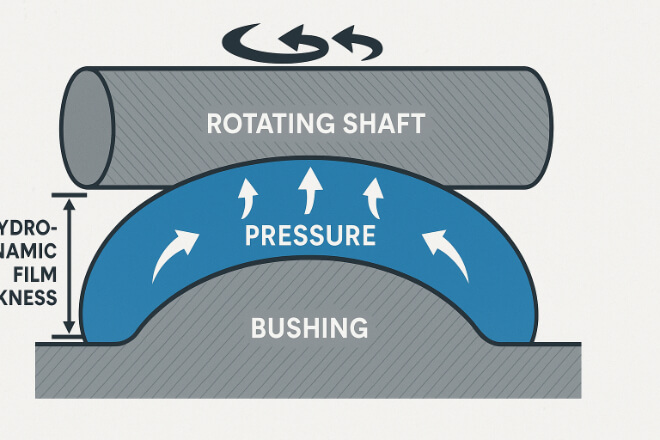

Lubrication creates a thin film between the bushing and the rotating shaft, preventing direct metal-to-carbide contact. This reduces friction, wear, and temperature rise.

Proper lubrication helps:

Minimize energy loss from friction

Prevent surface scoring and pitting

Reduce risk of seizure under load

Improve operating smoothness

When lubrication fails, frictional heat builds rapidly — leading to bushing surface oxidation, loss of độ cứng, and cracking.

Types of Lubricants for Tungsten Carbide Bushings

Choosing the correct lubricant depends on the application and environment.

Below is a comparison of common lubricant types:

| Lubricant Type | Đặc trưng | Best Application |

|---|---|---|

| Mineral Oil | Low cost, stable under normal temperature | General industrial pumps and compressors |

| Synthetic Oil | High thermal stability, long life | High-temperature or continuous-duty machinery |

| Water-Based Coolant | Excellent cooling, but may cause corrosion | Chemical processing and marine applications |

| Grease | Good for low-speed or intermittent use | Slow-moving shafts or start-stop systems |

Note: Always ensure compatibility between the lubricant and binder material (Co or Ni) in tungsten carbide, since certain chemicals can cause binder leaching.

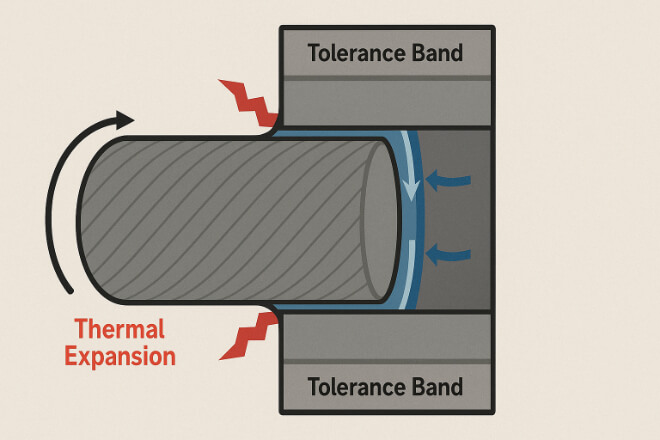

Lubrication Film and Clearance Design

The lubrication film thickness depends on operating speed, load, viscosity, and surface finish.

A clearance that’s too tight may squeeze out the lubricant; too loose may cause instability.

For precision bushings, the clearance should maintain an optimum hydrodynamic film.

Typical design guidelines:

Film thickness: 1–10 µm (depending on speed)

Surface finish: Ra 0.1–0.2 µm

Clearance: 0.005–0.020 mm

The film acts as a “cushion,” supporting the shaft while minimizing direct contact between metal and carbide.

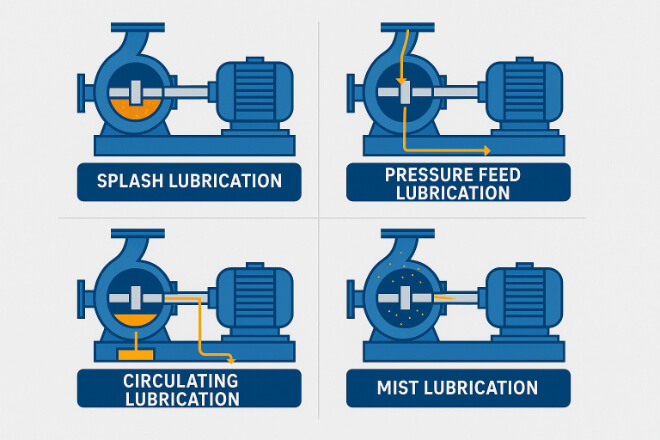

Lubrication Methods

Lubrication can be applied in various ways, depending on the machinery design:

1). Splash Lubrication:

Simple system where rotating components dip into oil.

Suitable for low- to medium-speed equipment.

2). Pressure Feed Lubrication:

Oil is pumped directly into the clearance under pressure.

Ideal for heavy loads or high-speed systems.

3). Circulating Lubrication System:

Continuous flow of filtered oil to and from a reservoir.

Provides both lubrication and cooling effect.

4). Mist or Spray Lubrication:

Fine oil mist reaches the bushing area with minimal waste.

Common in air compressors or small pumps.

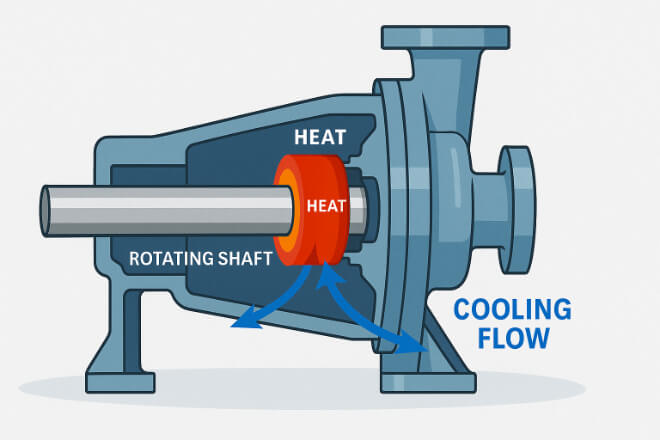

Importance of Cooling in Tungsten Carbide Bushings

Tungsten carbide can handle high temperatures, but excessive localized heat can still lead to damage.

When heat is not controlled, it causes:

Thermal cracking

Binder phase softening

Dimensional distortion

Increased friction and surface oxidation

Efficient cooling keeps the temperature within safe limits and maintains the correct oil film viscosity.

Common Cooling Methods

The following systems are used to manage temperature around bushings and shafts:

| Cooling Method | Working Principle | Thuận lợi |

|---|---|---|

| Oil Circulation Cooling | Oil absorbs heat and returns to tank for cooling | Combines lubrication and cooling in one system |

| Water Jacket Cooling | Water circulates around housing to remove heat | High efficiency for large industrial systems |

| Air Cooling | Forced air removes heat from bushing housing | Simple and clean, used in dry environments |

In demanding environments (like dầu khí or chemical processing), a combined oil-lubrication and water-jacket system gives the best thermal stability.

Monitoring Lubrication and Cooling Performance

To maintain reliable operation, periodic monitoring is essential:

Oil temperature: Should stay between 40°C and 80°C.

Oil flow rate: Verify constant flow through channels or grooves.

Filter condition: Replace or clean filters regularly.

Surface temperature: Check housing and shaft temperatures using infrared sensors.

Oil analysis: Monitor viscosity, water content, and contamination.

An early rise in temperature or decrease in oil pressure is a warning sign that lubrication or cooling is failing.

Common Lubrication and Cooling Issues

Even well-designed systems can face issues that cause premature wear.

The table below lists common problems and solutions.

| Issue | Possible Cause | Recommended Action |

|---|---|---|

| Excessive Heat | Low oil flow or blocked coolant channels | Inspect and clean circulation lines |

| Bushing Wear or Scoring | Insufficient lubrication film | Check clearance and lubricant viscosity |

| Corrosion or Pitting | Coolant contamination or poor material choice | Use WC-Ni or coated bushings with clean fluid |

Maintaining clean lubrication circuits and proper oil filtration is the simplest way to avoid costly failures.

Best Practices Summary

To achieve optimal lubrication and cooling performance:

Maintain clean, temperature-controlled oil systems.

Choose lubricants compatible with tungsten carbide binders.

Design clearance and film thickness carefully.

Use circulating lubrication in high-load systems.

Monitor flow, temperature, and contamination regularly.

Following these practices ensures smooth operation, longer life, and less downtime.

Phần kết luận

Proper lubrication and cooling are as important as material quality in achieving reliable operation of tungsten carbide bushings.

By selecting suitable lubricants, designing effective flow systems, and monitoring conditions regularly, companies can prevent wear, cracking, and failure.

These best practices not only improve performance but also reduce energy loss and extend equipment lifespan — a major win for any operation.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.