Vòng đệm cacbua are critical components used in pumps, compressors, and van across industries like power generation, chemical processing, and dầu khí. Their primary role is to prevent leaks and maintain pressure integrity within systems.

One of the key factors influencing seal performance is tolerance, which refers to the allowable variation in the dimensions of the seal faces.

The two main types of tolerance for carbide seal rings are open tolerance and ground tolerance.

Understanding the differences between these two types and how they affect leakage control can help decision-makers select the right seals for their applications, ensuring safety and efficiency in their operations.

What Are Tolerances and Why Do They Matter?

In simple terms, tolerance refers to the permissible variation in the dimensions of a manufactured part.

For carbide seal rings, tolerance affects how well the seal faces fit together and whether they create a proper seal.

Open tolerance: The manufacturing process allows for more variation in the dimensions.

Ground tolerance: The seal faces are precisely ground, providing tighter control over dimensions.

The tighter the tolerance, the more precise the seal faces, which directly impacts leakage control.

Open Tolerances for Carbide Seal Rings

Open tolerance carbide seal rings are produced with less strict dimensional control.

This method is typically faster and less expensive. However, it also introduces some risks when it comes to leakage control.

1). Advantages

Cost-effective: Open tolerance seals are cheaper to produce.

Faster production times: Since less precision is required, manufacturing is quicker.

2). Disadvantages

Higher risk of leakage: Variations in seal face dimensions can cause improper seating and allow fluid to leak.

Potential for uneven wear: If the faces don’t align perfectly, some areas may wear out faster, leading to premature failure.

Reduced performance in high-pressure or high-temperature systems: Open tolerance seals might not provide a consistent barrier under extreme conditions.

3). Best Use Cases

Low-pressure systems: Open tolerance carbide seals may work in applications where leakage risks are lower.

Non-critical applications: Systems that don’t operate under extreme conditions can benefit from cost savings without sacrificing too much performance.

Ground Tolerances for Carbide Seal Rings

Ground tolerance carbide seal rings are manufactured with precise control over dimensions.

This process involves grinding the seal faces to achieve exact specifications, resulting in a tighter and more reliable seal.

1). Advantages

Lower leakage risk: Tight tolerances ensure that the seal faces fit together perfectly, reducing the chances of leaks.

Improved wear resistance: The precise alignment helps prevent uneven wear and extends the life of the seals.

Better performance under high-pressure or high-temperature conditions: Ground tolerance seals maintain their sealing capability even in harsh environments.

2). Disadvantages

Higher cost: The increased manufacturing precision makes these seals more expensive.

Longer production times: Grinding the seal faces takes more time compared to open tolerance production.

3). Best Use Cases

High-pressure systems: Ground tolerance seals are ideal for pumps, compressors, and valves that operate under high pressure or extreme temperatures.

Critical applications: Systems where leaks could lead to safety concerns, environmental damage, or significant downtime benefit most from ground tolerance seals.

How Open vs Ground Tolerances Impact Leakage Control

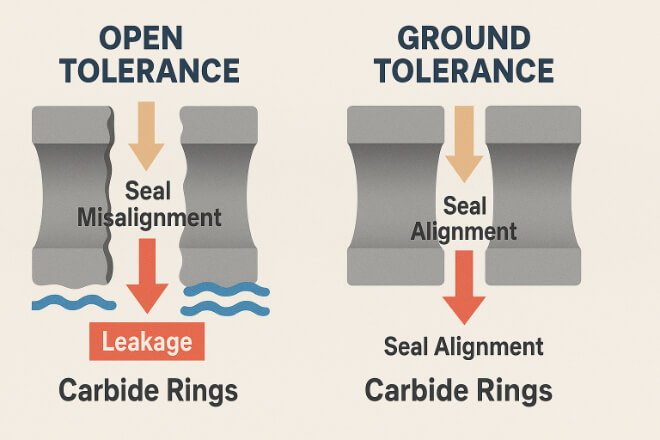

1). Seal Face Alignment

The fit of the seal faces is crucial to leakage control. A proper seal requires that the two faces meet perfectly, creating a tight barrier.

Open tolerance can lead to variations in how the faces meet, which may cause gaps or uneven pressure distribution, leading to leakage.

Ground tolerance ensures that the seal faces align perfectly, maintaining a consistent sealing surface and significantly reducing leakage risk.

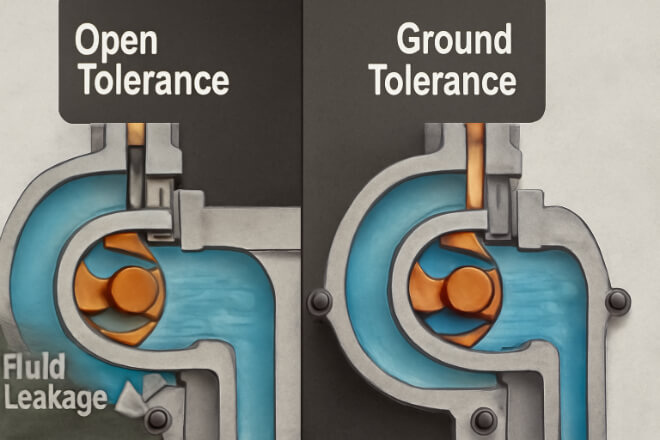

2). Pressure and Temperature Variations

In high-pressure or high-temperature systems, even small variations in the seal faces can lead to seal failure.

Open tolerance seals are more likely to fail under fluctuating conditions, as slight misalignments cause stress points that can lead to cracks or leaks.

Ground tolerance seals maintain consistent performance under these conditions, as the precise fit allows the seal faces to endure changes in pressure and temperature without deforming.

3). Long-Term Performance

Over time, the wear of the seal faces becomes critical to performance.

Open tolerance seals may experience uneven wear because of misalignments, leading to early failure and increased maintenance costs.

Ground tolerance seals wear more evenly, ensuring a longer lifespan and reducing the frequency of replacements.

Best Applications for Open Tolerances vs Ground Tolerances

| Ứng dụng | Open Tolerances | Ground Tolerances |

|---|---|---|

| Low-pressure systems | Ideal for cost-saving in non-critical systems | Not recommended due to cost |

| High-pressure or high-temperature systems | Risk of leakage and wear | Best choice for maintaining seal integrity |

| Critical applications (e.g., chemicals, food-grade) | Not ideal for reliability and safety | Most reliable for safety-critical applications |

Maintenance and Leakage Prevention Tips

Inspect seals during planned downtime for wear or damage.

Use a proper installation procedure to ensure the seal faces align correctly.

Keep the sealing environment clean to avoid contamination.

Choose the correct tolerance based on the operating conditions and fluid type.

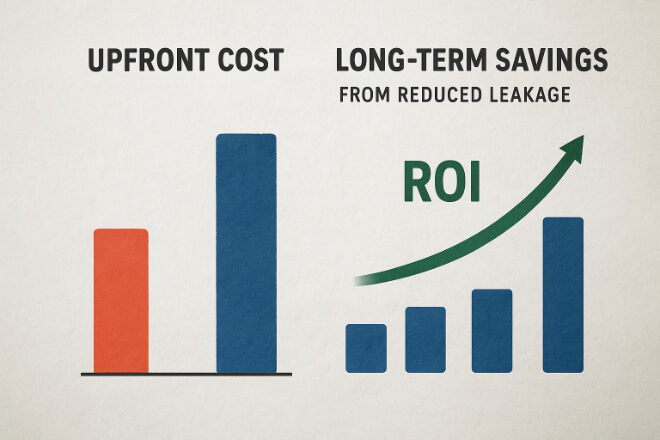

Cost Considerations and ROI

Open tolerance seals are cost-effective for systems where leakage risks are minimal.

Ground tolerance seals have a higher initial cost but provide longer service life and lower overall maintenance costs.

Investing in ground tolerance carbide seals is generally more cost-effective in the long term for critical systems, especially when downtime is expensive or safety is a concern.

Phần kết luận

Choosing the right tolerance for carbide seal rings is crucial for ensuring optimal leakage control.

Open tolerance seals offer a cost-effective solution for low-pressure or non-critical systems, while ground tolerance seals are best suited for high-pressure, high-temperature, and critical applications.

For decision-makers, selecting the appropriate tolerance level based on operational needs ensures reliable performance, reduces leakage, and improves long-term cost efficiency.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.