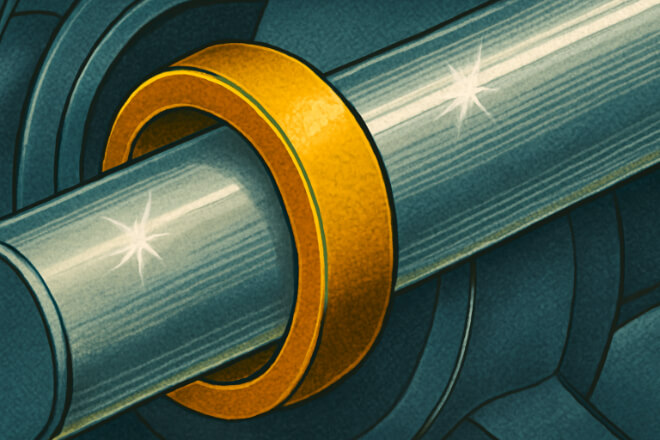

Ống lót cacbua vonfram are widely used in applications where durability and khả năng chống mài mòn are critical.

These bushings are often paired with a shaft, which provides a counterface against which the bushing operates.

Selecting the right shaft counterface material is crucial to ensure optimal performance, reduce wear, and extend the service life of both the bushing and the shaft.

In this article, we will explore the factors to consider when selecting shaft counterface materials for tungsten carbide bushings.

The best material choices for various applications, and how to achieve the perfect match for your system.

What Is a Shaft Counterface?

The shaft counterface is the surface of the shaft that comes into contact with the bushing. It plays a critical role in how well the bushing functions and how long it lasts.

A well-chosen counterface material minimizes friction, reduces wear, and ensures that the bushing and shaft work together efficiently.

The interaction between the counterface and the bushing can affect factors like:

Khả năng chống mài mòn: A smoother counterface reduces wear on the bushing.

Friction: Proper counterface material selection helps lower friction.

Alignment: The counterface should align well with the bushing to avoid uneven wear.

The counterface material must be compatible with the bushing material to avoid issues such as excessive wear, galling, or seizure.

Key Considerations for Selecting Shaft Counterface Materials

When choosing the right counterface material, several key factors must be taken into account. The ideal counterface material will depend on the operating conditions and the material of the tungsten carbide bushing.

Factors to Consider:

The hardness of the counterface material should complement the hardness of the tungsten carbide bushing.

If the counterface is too soft, it can wear down quickly. If it is too hard, it can cause excessive wear on the bushing.

Surface Finish:

The counterface surface should be smooth, as rough surfaces can lead to higher friction and faster wear of the bushing.

In many industries, the counterface is exposed to chemicals or moisture.

It is important to choose a material that resists corrosion to ensure long-lasting performance.

Temperature Resistance:

For applications involving high temperatures, the counterface material should be able to withstand heat without degrading.

By selecting the right counterface material based on these factors, you can ensure that the tungsten carbide bushing performs efficiently and lasts longer.

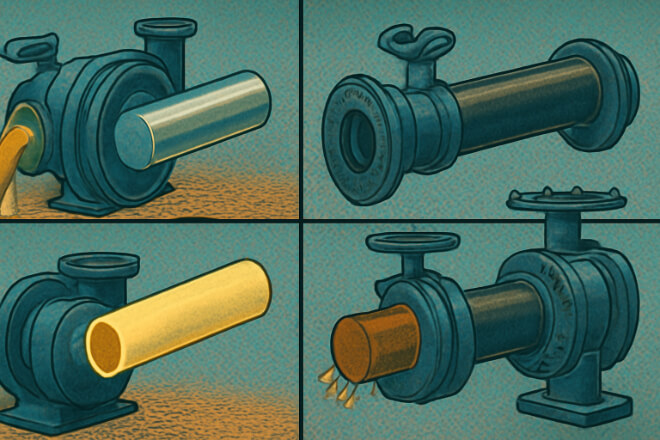

Common Shaft Counterface Materials

Several materials are commonly used for shaft counterfaces, each with its own set of advantages and drawbacks. Here are some of the most popular materials:

1). Stainless Steel

Advantages: Stainless steel is widely used for shaft counterfaces due to its excellent khả năng chống ăn mòn and strength. It works well with tungsten carbide bushings in many applications.

Applications: Ideal for chemical processing, food and beverage industries, and marine environments.

Considerations: Stainless steel can be prone to galling when in contact with tungsten carbide, especially in high-pressure applications.

2). Carbon Steel

Advantages: Carbon steel is another commonly used material for counterfaces. It is durable, cost-effective, and can be easily hardened.

Applications: Often used in general industrial applications with moderate wear and pressure.

Considerations: It is not as corrosion-resistant as stainless steel, so it may not be suitable for aggressive environments.

3). Ceramic Materials (e.g., Al2O3)

Advantages: Ceramic counterfaces offer very low friction and high wear resistance, making them ideal for high-performance applications.

Applications: Used in high-speed machinery, pumps, and other systems requiring low friction and excellent khả năng chống mài mòn.

Considerations: Ceramics are brittle and can crack under impact or extreme pressure.

4). Hardened Steel

Advantages: Hardened steel offers excellent wear resistance and is less prone to deformation under load.

Applications: Commonly used in heavy-duty applications, such as mining and material handling systems.

Considerations: While durable, hardened steel can be prone to galling when in contact with tungsten carbide under high loads.

Matching Shaft Counterface Materials with Tungsten Carbide Bushings

When choosing a shaft counterface material for tungsten carbide bushings, it is important to match the material properties to achieve the best performance and longevity.

Material Compatibility:

Stainless Steel and Tungsten Carbide:

Stainless steel is a good match for tungsten carbide bushings in most applications, as it offers excellent khả năng chống ăn mòn and can handle moderate wear.

However, care must be taken to ensure proper surface finish and alignment to prevent galling.

Carbon Steel and Tungsten Carbide:

Carbon steel is a cost-effective choice, but its wear resistance is lower than stainless steel, so it is best suited for less demanding applications.

Ceramics and Tungsten Carbide:

Ceramic counterfaces paired with tungsten carbide bushings offer superior khả năng chống mài mòn and low friction.

However, ceramics are brittle and should be used in applications where impact and shock loading are not common.

Hardened Steel and Tungsten Carbide:

Hardened steel is a strong, durable option that pairs well with tungsten carbide in high-pressure and high-wear applications.

However, it may be more prone to galling without proper lubrication.

Matching the right counterface material with the tungsten carbide bushing ensures optimal performance and reduces maintenance costs over time.

Benefits of Proper Shaft Counterface Material Selection

Choosing the right counterface material for ống lót cacbua vonfram has several key benefits, including:

Extended bushing lifespan: By reducing wear and friction, the bushing can last longer, reducing the frequency of replacements.

Improved system efficiency: Less friction and wear mean smoother operation and lower energy consumption.

Lower maintenance costs: Choosing the right counterface material helps minimize wear-related issues, reducing downtime and maintenance expenses.

Phần kết luận

Selecting the right shaft counterface material is crucial for ensuring the longevity and efficiency of tungsten carbide bushings.

By considering factors such as hardness, surface finish, corrosion resistance, and temperature stability, you can choose the ideal material for your application.

Whether you opt for stainless steel, carbon steel, ceramic, or hardened steel, each material has its own set of advantages.

By matching the counterface material to the operating conditions, you can optimize the performance of your system and reduce maintenance costs over time.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.