Ống lót cacbua vonfram are designed to handle tough industrial environments, but they can wear out prematurely if paired with shafts that don’t meet the right độ cứng requirements.

The hardness of the shaft has a significant impact on the lifespan and performance of tungsten carbide bushings.

In this article, we will explore the importance of shaft hardness, how it protects WC bushings, and what the right hardness values should be for different applications.

Why Shaft Hardness Matters for Tungsten Carbide Bushings

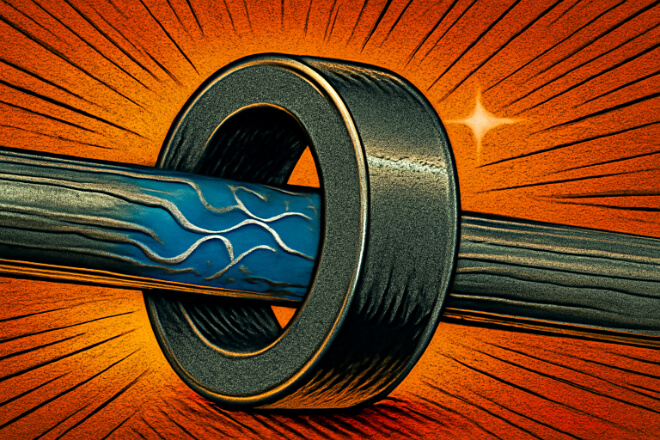

The hardness of the shaft paired with a tungsten carbide bushing affects the wear and tear each component experiences during operation.

If the shaft is too soft, it can wear down quickly, leading to uneven wear on the bushing, potential cracks, and even premature failure.

Key Factors Affected by Shaft Hardness:

Khả năng chống mài mòn: A harder shaft ensures minimal wear on the bushing surface.

Load Distribution: Harder shafts can better distribute the mechanical load across the bushing.

Friction Control: Proper hardness minimizes friction and the risk of galling.

Using the wrong shaft hardness can reduce the efficiency of your system and lead to costly repairs.

Understanding the Relationship Between Shaft Hardness and Bushing Wear

Tungsten carbide is a very hard material, but it’s also brittle. To ensure that WC bushings last longer, the shaft paired with them must be hard enough to resist wear without damaging the bushing surface.

1). How Hardness Affects Wear:

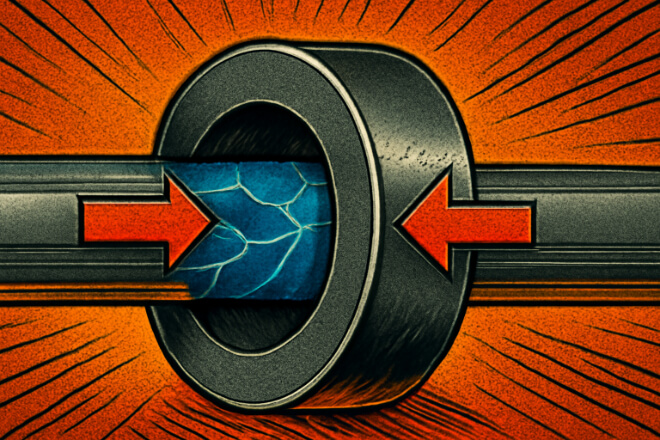

Too Soft: If the shaft is softer than the bushing, it will wear more quickly, causing the bushing to take on more of the mechanical load.

Too Hard: A shaft that is too hard can cause damage to the bushing through excessive localized stress and microfractures.

2). The Ideal Độ cứng for Shafts

To protect tungsten carbide bushings, the shaft must have an appropriate hardness level, typically measured by the Rockwell or Vickers scale.

Too much or too little hardness can lead to issues, so it’s important to find a balance.

The Ideal Shaft Hardness for Tungsten Carbide Bushings

For optimal performance, the shaft hardness should be chosen based on the operating conditions and the material of the bushing.

1). Common Shaft Hardness Ranges:

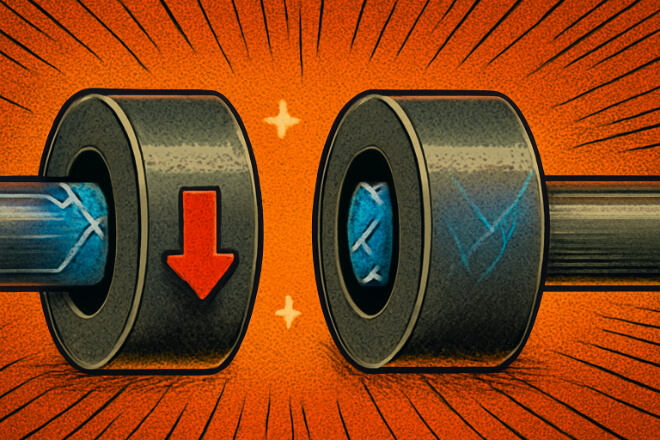

For WC-Co Bushings: Shafts should have a hardness between 55-62 HRC (Rockwell C) to ensure minimal wear and compatibility.

For WC-Ni Bushings: A slightly lower shaft hardness of 50-58 HRC is recommended to match the toughness of the WC-Ni material.

2). Why This Matters

Độ dẻo dai vs Độ cứng: For applications with high shock loads, a tougher shaft with slightly lower hardness (50-55 HRC) is preferred. For precision applications where wear resistance is key, a harder shaft is required.

Effects of Shaft Hardness on Bushing Lifespan

Shaft độ cứng impacts the longevity of tungsten carbide bushings in different ways.

In general, the harder the shaft, the longer the bushing will last under proper operating conditions. However, excessive hardness can lead to another set of problems.

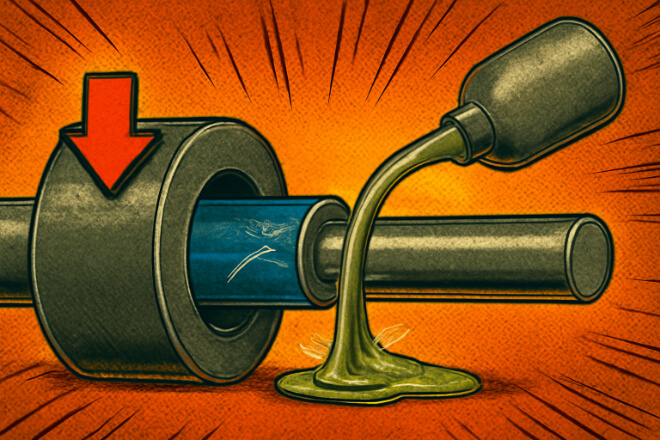

1). Too Soft Shaft

A shaft that is too soft can cause:

Excessive wear: The softer material wears faster, causing increased friction and damage to the bushing.

Misalignment: A soft shaft may bend under load, leading to misalignment and uneven wear on the bushing.

2). Too Hard Shaft

A shaft that is too hard can cause:

Localized Stress: The harder shaft may cause concentrated pressure points on the bushing, leading to cracks.

Increased Friction: A very hard shaft can generate more friction, leading to heat buildup and premature failure.

Selecting the Right Shaft Hardness for Different Applications

The optimal shaft độ cứng depends on the application and the type of tungsten carbide bushing used.

Different industries and applications require different hardness levels for both the shaft and bushing.

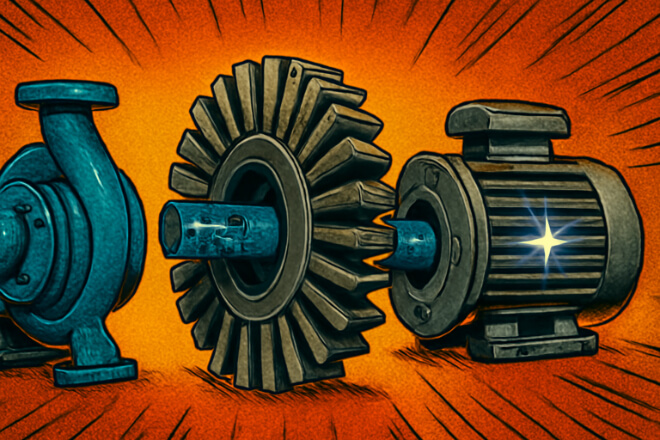

1). For High-Speed Applications

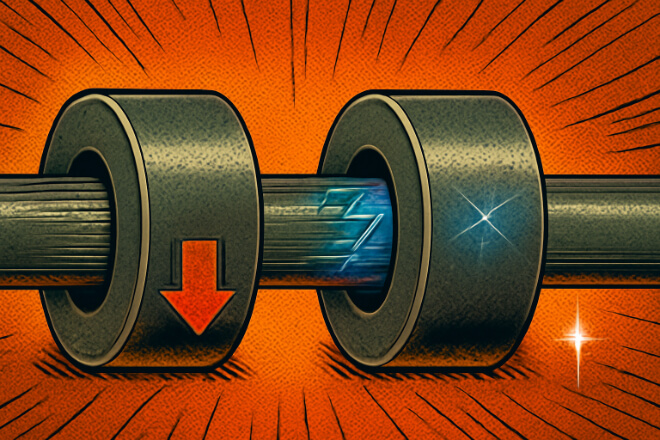

In high-speed applications, where friction is a significant concern, the shaft should have a hardness of 58-62 HRC.

This will help reduce wear while maintaining a smooth operation. For example, centrifugal pumps or turbines often require shafts on the higher end of this scale.

2). For Heavy Load Applications

In heavy load and shock-resistant applications, such as mining or dredging, a slightly lower shaft hardness of 50-55 HRC may be appropriate.

This allows for increased độ dẻo dai while reducing the risk of damaging the bushing under high impact.

Measuring and Testing Shaft Hardness

It’s important to test the shaft độ cứng regularly to ensure that it meets the required specifications. There are several methods for measuring shaft hardness:

Common Hardness Testing Methods:

Rockwell Hardness Test (HRC): Measures the resistance of a material to deformation.

Vickers Hardness Test: Uses a diamond indenter to measure the hardness of the shaft and provides more accurate results for small or thin materials.

Both tests give you a numerical value that can be compared against the required hardness range for your specific tungsten carbide bushing.

Preventing Damage from Incorrect Shaft Hardness

In cases where the shaft độ cứng doesn’t meet the required standards, several steps can be taken to prevent damage to the bushing:

1). Replacing the Shaft

If the shaft hardness is too low or too high, replacing it with a shaft that fits the recommended hardness range is essential.

2). Surface Hardening

For shafts that are too soft, surface hardening methods like nitride hardening or induction hardening can be used to increase the surface hardness without affecting the core strength.

3). Using Lubrication

Proper lubrication can reduce the friction between the shaft and bushing, minimizing the impact of slight hardness mismatches.

Phần kết luận

The hardness of the shaft plays a critical role in the longevity and performance of tungsten carbide bushings.

For best results, shafts should fall within the recommended hardness range, ensuring they complement the hardness of the bushing.

Regular testing and maintenance, as well as choosing the correct materials and lubrication, will help prevent premature wear and damage to your WC bushings.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.