Every industry needs machines that run safely and reliably. In pumps, compressors, turbines, and mixers, seal rings are key parts. They stop leaks, protect the system, and extend machine life.

While standard seal rings work for many cases, some industries need custom vòng đệm cacbua vonfram to handle special conditions.

Custom design is not just about size. It is about choosing the right material grade, binder, coating, and shape to meet exact operating needs.

For decision-makers, investing in custom seal rings means fewer failures, less downtime, and stronger long-term savings.

Vòng đệm cacbua vonfram là gì?

Tungsten carbide seal rings are mechanical sealing parts made by sintering tungsten and carbon with a binder (nickel or cobalt).

They are used in machines where fluids or gases must be contained under pressure.

Core properties:

Rất cao độ cứng

High temperature stability

Long service life in harsh environments

Custom versions are made to fit specific machines and conditions, rather than one-size-fits-all models.

Why Customization Matters in Seal Rings

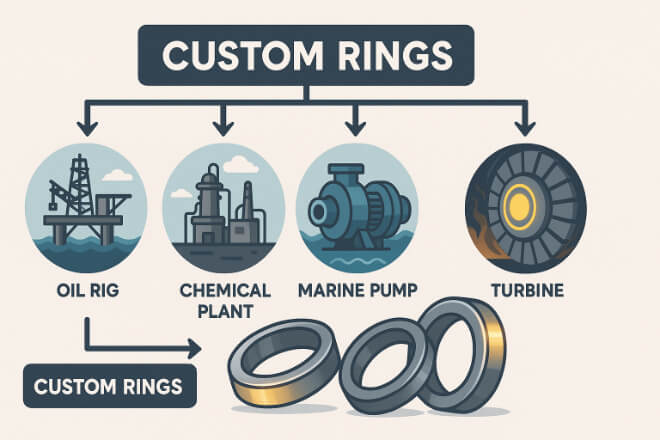

Not all machines face the same environment. A pump in a chemical plant does not face the same challenges as one in an offshore oil rig.

Key reasons for customization:

Different fluids: Corrosive acids, seawater, or abrasive slurry

Different pressure: Low-pressure mixers vs. high-pressure turbines

Different temperature: Normal water pumps vs. hot steam compressors

Different speed: Slow-moving mixers vs. high-speed turbines

By customizing seal rings, companies ensure the product matches the real conditions, improving safety and reliability.

Benefits of Custom Tungsten Carbide Seal Rings

1). Better Fit and Performance

Custom rings are designed to fit exactly into the machine. This ensures a perfect seal and reduces the risk of leaks.

2). Higher Reliability

By selecting the right grade and binder, custom rings last longer in specific environments.

3). Lower Maintenance Costs

Custom rings reduce breakdowns, cutting both repair time and replacement frequency.

4). Improved Safety

Leaks in dầu, khí đốt, or chemical systems can be dangerous. Custom rings lower the risk of accidents.

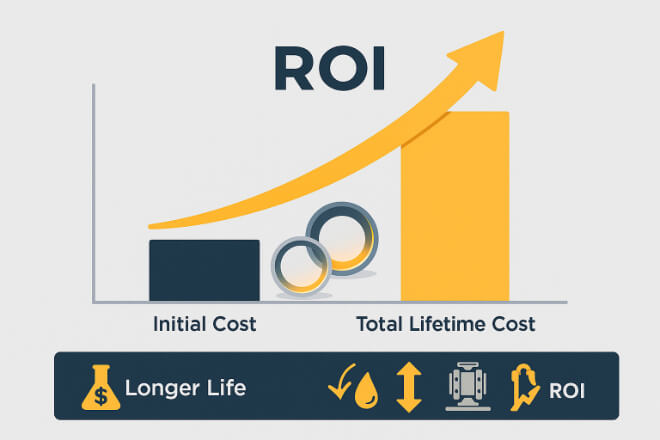

5). Long-Term ROI

Though custom designs cost more upfront, they deliver savings by extending lifespan and reducing failures.

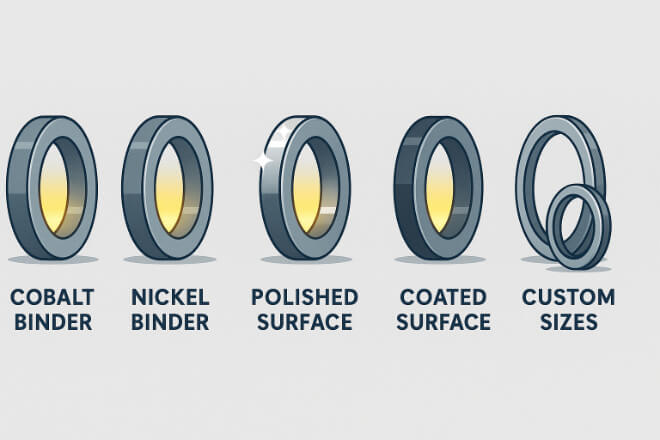

Customization Options

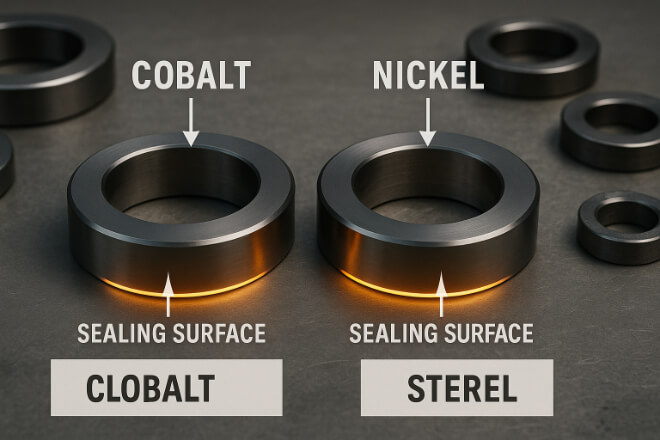

1). Loại chất kết dính

Nickel-bonded: Resists acids and seawater

Cobalt-bonded: Tougher against heavy load and impact

2). Hoàn thiện bề mặt

Polished rings for high-speed, low-friction systems

Coated rings (like DLC coatings) for extra wear protection

3). Size and Shape

Custom dimensions for pumps, turbines, or compressors that require non-standard designs

4). Industry-Specific Grades

- Composite grades for extreme thermal or abrasive conditions

Industry Use Cases for Custom Seal Rings

1). Dầu khí

Offshore rigs face high pressure, abrasive drilling mud, and seawater. Custom cobalt- or nickel-bonded rings ensure safety and uptime.

2). Nhà máy hóa chất

Pumps and mixers handle acids and solvents. Custom nickel-bonded rings prevent corrosion failures.

3). Marine and Shipping

Seawater is highly corrosive. Custom nickel-bonded rings extend service life in ship pumps and offshore platforms.

4). Sản xuất điện

Turbines and steam systems run at high pressure and heat. Custom cobalt-bonded rings deliver toughness and stability.

5). Food and Pharmaceuticals

Custom rings are designed to meet hygiene and safety standards while ensuring leak-free operation.

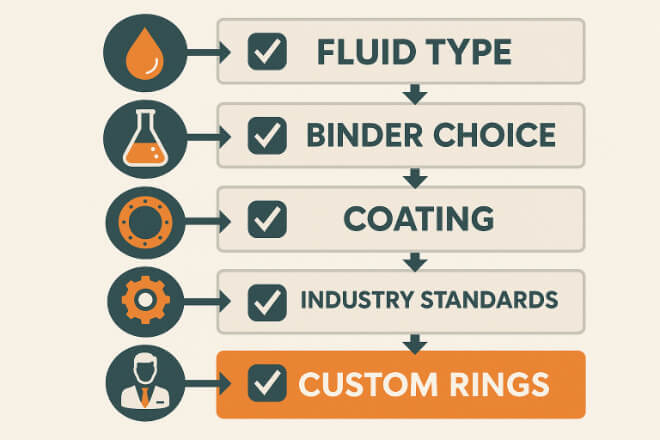

Steps for Selecting a Custom Seal Ring

Define Operating Conditions: Fluid type, pressure, temperature, and speed.

Choose Binder Material: Nickel for corrosion, cobalt for độ dẻo dai.

Select Surface Finish or Coating: Polished or coated depending on friction and wear.

Check Industry Standards: Ensure compliance with ISO and safety regulations.

Work with Reliable Suppliers: Choose suppliers with customization experience and technical support.

Mistakes to Avoid in Seal Ring Selection

Choosing only by price instead of lifetime value

Ignoring chemical compatibility with the fluid

Using standard rings in extreme environments

Not planning for regular inspection and replacement

Correct customization avoids these costly errors.

Maintenance and Replacement of Custom Seal Rings

Even with the best customization, maintenance is required:

Inspect regularly for cracks, wear, or corrosion

Replace before total failure occurs

Always use the same grade and dimensions for replacement

Recycle worn tungsten carbide to save cost and reduce waste

Cost and ROI for Custom Solutions

Custom seal rings cost more at the start, but decision-makers gain:

Longer service life (5–10x compared with steel seals)

Fewer shutdowns and less downtime

Safer, more reliable systems

Stronger long-term ROI

Nghiên cứu điển hình

1). Offshore Oil Platform

Switched to custom nickel-bonded rings for seawater pumps. Result: doubled service life and fewer emergency repairs.

2). Chemical Refinery

Custom corrosion-resistant rings reduced failure rates by 60%, saving both cost and downtime.

3). Power Plant

Custom cobalt-bonded rings lasted longer in high-pressure turbines, improving overall plant efficiency.

How to Source Custom Tungsten Carbide Seal Rings

When sourcing custom rings, companies should:

Work with suppliers offering both standard and custom designs

Verify ISO certification and industry track record

Ask for material recommendations based on actual operating data

Ensure local inventory for faster delivery

Phần kết luận

Custom tungsten carbide seal rings are a smart investment. They provide better fit, stronger performance, lower risks, and higher long-term returns compared with standard rings.

For decision-makers in oil & gas, chemical, marine, power, and food industries, custom solutions mean fewer failures, safer operations, and stronger profitability.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.