Ống lót cacbua vonfram are small components with a big impact. They provide khả năng chống mài mòn, strength, and reliability in high-pressure and high-friction systems such as pumps, compressors, and turbines.

Behind every finished bushing is a complex manufacturing process that turns fine tungsten and metal powders into a precision-engineered part.

Each step — from powder preparation to final polishing — determines how long the bushing will last in service.

In this article, we’ll explain the complete manufacturing process of tungsten carbide bushings in simple terms, highlight why each step matters, and show how strict process control ensures durability and precision.

Raw Material Selection

The process begins with choosing the right tungsten carbide (WC) powder and binder metal. The most common binders are cobalt (Co) and nickel (Ni).

The combination ratio affects độ cứng, độ dẻo dai, Và khả năng chống ăn mòn. Fine-grain powders are used for bushings that need high strength and mirror surface finishes.

1). Common Powder Composition

| Component | Weight Percentage | Function |

|---|---|---|

| Tungsten Carbide (WC) | 88–94% | Provides hardness and wear resistance |

| Coban (Co) | 6–12% | Adds toughness and bonding strength |

| Niken (Ni) | 6–10% (optional) | Improves corrosion resistance |

The right balance between WC and binder defines how the bushing will perform — a higher binder content improves toughness, while a lower one increases hardness.

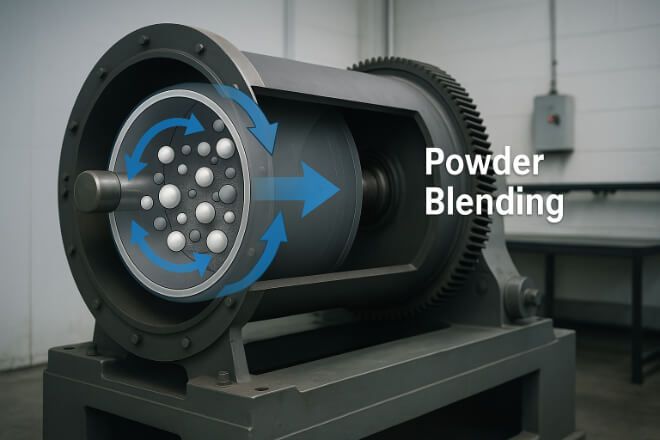

Powder Mixing and Homogenization

The selected powders are mixed in a ball mill with a small amount of ethanol or paraffin as a binder liquid. The goal is to achieve uniform particle distribution.

This step ensures that the final carbide has consistent Tỉ trọng and mechanical properties across the entire part.

Duration: 24–48 hours

Outcome: Fine, evenly mixed powder ready for pressing

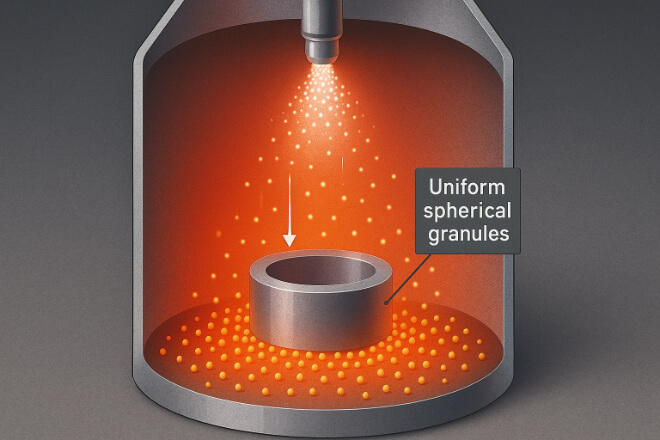

Spray Drying and Granulation

The mixed slurry is fed into a spray dryer, where hot air converts it into free-flowing spherical granules.

These granules are easy to press and maintain consistent Tỉ trọng during compaction.

This step avoids segregation and helps achieve uniform shrinkage during sintering later.

Pressing and Compact Forming

The powder is compacted into a rough ring shape called a green compact using hydraulic or isostatic pressing.

Pressing Parameters

| Pressing Method | Pressure | Shape Accuracy |

|---|---|---|

| Uniaxial Pressing | 150–250 MPa | Good (for simple shapes) |

| Cold Isostatic Pressing (CIP) | 200–300 MPa | Excellent (uniform density) |

The green compact at this stage is still fragile, with a porosity level of 40–50%.

Sintering — Turning Powder into Solid Metal

The green rings are placed in a vacuum or hydrogen sintering furnace and heated to around 1350–1500°C.

During this stage:

The binder metal melts and bonds WC grains.

Các porosity disappears.

Tỉ trọng reaches over 99% of theoretical value.

The shrinkage during sintering is around 18–22%, which is why accurate dimension control during pressing is essential.

After sintering, the bushings become extremely hard and ready for rough machining.

Rough and Finish Machining

After sintering, the bushing is hard enough to require diamond tools for machining.

Rough grinding shapes the outer and inner diameters.

Fine grinding achieves closer tolerances.

The bushing’s concentricity and roundness are maintained within microns.

This stage defines the final geometry before surface finishing.

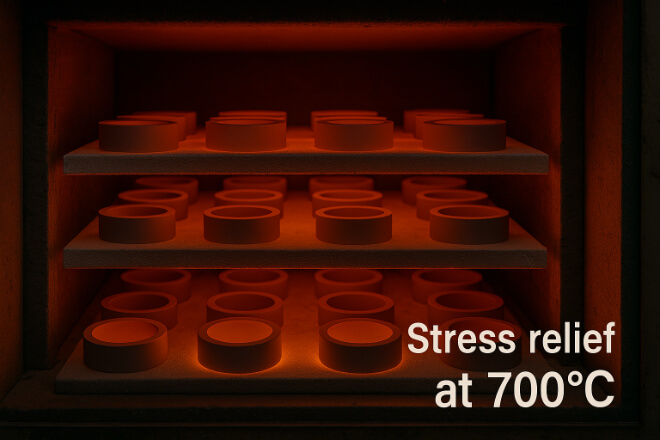

Stress Relief Heat Treatment

Residual stresses from grinding are removed through low-temperature annealing (600–800°C).

This prevents micro-cracks and dimensional warping in later stages, ensuring that the bushing maintains flatness during operation.

Lapping and Polishing

This step creates the mirror-smooth surfaces that tungsten carbide bushings are known for.

Using diamond abrasives and precise lapping machines, the surface roughness is reduced to Ra ≤ 0.05 µm.

Polishing ensures:

Minimal friction between moving parts

Long seal life

Better fluid film stability

Inspection and Quality Control

Every bushing undergoes strict testing for dimensions, density, and flatness.

1). Inspection Checklist

| Parameter | Typical Standard | Test Method |

|---|---|---|

| Độ cứng | 88–92 HRA | Rockwell A test |

| Tỉ trọng | ≥ 14.0 g/cm³ | Archimedes method |

| Flatness | ≤ 0.3 µm | Optical interferometer |

| Hoàn thiện bề mặt | Ra ≤ 0.05 µm | Profilometer |

Only bushings meeting all these standards move to the final packaging stage.

Cleaning and Packaging

Before shipping, each bushing is ultrasonically cleaned using deionized water or alcohol to remove oil and particles.

After drying, they are sealed in anti-static vacuum packaging to prevent corrosion and dust contamination.

This ensures they arrive ready for installation in clean or precision applications, including pumps, compressors, and turbines.

End-to-End Process Summary

| Step | Process Description | Mục đích |

|---|---|---|

| 1 | Powder selection | Defines final strength and toughness |

| 2 | Mixing and granulation | Ensures even particle distribution |

| 3 | Pressing | Forms the green compact |

| 4 | Thiêu kết | Creates full density and strength |

| 5 | Grinding and polishing | Achieves final geometry and finish |

| 6 | Inspection and cleaning | Guarantees quality and precision |

Phần kết luận

The manufacturing process of tungsten carbide bushings is a precise balance of material science, process control, and quality assurance.

Every step — from powder preparation to polishing — determines the performance, durability, and reliability of the final product.

For decision-makers, understanding this workflow helps identify trusted suppliers capable of meeting strict tolerances and delivering consistent quality for high-demand industrial systems.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.