Các bộ phận mài mòn cacbua are used in industries like khai thác mỏ, tạo hình kim loại, dầu khí, and manufacturing because of their hardness and durability.

However, even carbide has limits. In extreme environments—high temperatures, heavy abrasion, or corrosive conditions—uncoated carbide can wear out faster.

This is where coatings come in. A high-quality coating can extend the life of carbide parts, reduce friction, improve heat resistance, and protect against corrosion.

For decision-makers, understanding coating technology is essential for improving productivity and lowering maintenance costs.

In this article, we explore:

Why coatings are used on carbide wear parts.

Different coating types and their benefits.

How coatings improve performance in real-world applications.

Key factors to consider when choosing a coating.

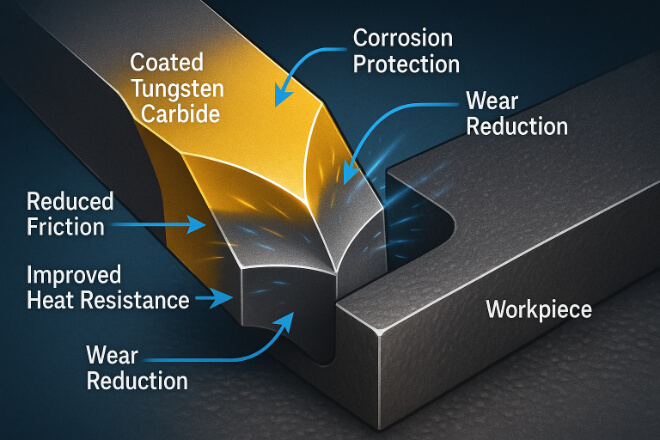

Why Coatings Are Applied to Carbide Wear Parts

Even though tungsten carbide is extremely hard, its surface can still suffer from:

Abrasive wear from hard particles.

Corrosion from chemicals or moisture.

Oxidation at high temperatures.

Frictional heat during high-speed operations.

Coatings act as a protective layer. They:

Reduce direct contact between the carbide and the work material.

Improve resistance to heat, wear, and chemical attack.

Help maintain sharpness and shape for longer periods.

Impact for Businesses: Coatings can reduce downtime, lower replacement costs, and increase efficiency.

Common Coating Types for Carbide Wear Parts

| Loại lớp phủ | Lợi ích chính | Tốt nhất cho |

|---|---|---|

| TiN (Titan Nitride) | High hardness, reduced friction, golden finish | General machining, cutting tools |

| TiAlN / AlTiN (Titanium Aluminum Nitride) | Excellent heat resistance, oxidation protection | High-speed and dry cutting |

| DLC (Carbon giống kim cương) | Ultra-low friction, wear resistance | Non-ferrous machining, sealing parts |

| Kim cương CVD | Extreme hardness, abrasion resistance | Composites, graphite, ceramics |

| CrN (Crom Nitride) | Chống ăn mòn và mài mòn | Food processing, chemical industry |

How Coatings Improve Carbide Wear Performance

Reduced Friction

A smooth coating lowers friction between the tool and material.

Benefit: Less heat buildup, reduced wear rate, better surface finish.

Higher Temperature Resistance

Coatings like TiAlN form an oxide layer at high heat, protecting the tool from softening.

Benefit: Longer tool life in high-speed operations.

Better Corrosion Resistance

Coatings act as a barrier against chemicals, moisture, or acidic materials.

Benefit: Prevents pitting and material breakdown.

Increased Wear Resistance

Hard coatings like diamond significantly reduce abrasive wear.

Benefit: Maintains part geometry for longer periods.

Coating Application Methods

Different application techniques affect coating performance.

1). PVD (Physical Vapor Deposition)

Produces thin, hard coatings.

Great for precision tools and sharp edges.

2). CVD (Chemical Vapor Deposition)

Creates thicker coatings with strong adhesion.

Suitable for heavy-duty applications.

3). Electroplating

Cost-effective but less common for high-wear tools.

Used in specific industrial cases.

4). Thermal Spraying

Applies thicker, wear-resistant layers.

Suitable for large components.

Impact for Businesses: Choosing the right method ensures the coating matches the part’s application and operating environment.

Matching Coating to Application

Not all coatings work for every job. The right choice depends on:

Material being processed (steel, aluminum, composites).

Operating temperature.

Type of wear (abrasive, adhesive, corrosive).

Speed and load conditions.

Example:

For high-speed steel cutting, TiAlN offers the best heat resistance.

For graphite machining, diamond coatings are unmatched.

For wet or corrosive environments, CrN or DLC may be the better choice.

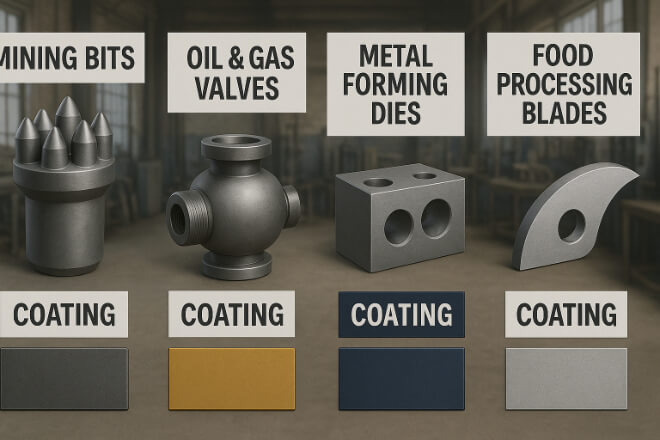

Real-World Industry Applications

1). Khai thác mỏ

Challenge: Extreme abrasion from rock and ore.

Solution: Thick CVD coatings or diamond layers for maximum hardness.

2). Dầu khí

Challenge: Corrosion from saltwater and chemicals.

Solution: CrN or multi-layer coatings for chemical resistance.

3). Metal Forming

Challenge: High pressure and friction during stamping.

Solution: TiN or TiAlN for reduced wear and longer die life.

4). Food Processing

Challenge: Hygiene and corrosion resistance.

Solution: CrN coatings for smooth, cleanable surfaces.

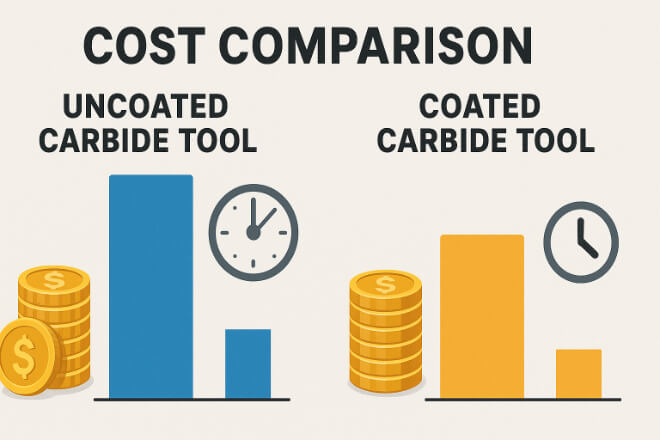

Cost vs. Benefit of Coated Carbide

While coatings increase initial part cost, they can reduce the cost per cycle by extending lifespan.

Example:

Uncoated carbide tool: 100 hours life, $200 cost → $2/hour.

Coated carbide tool: 300 hours life, $280 cost → $0.93/hour.

Conclusion: Coatings often pay for themselves through reduced downtime and replacement frequency.

Future Trends in Coating Technology

Nanostructured Coatings: Ultra-thin layers with unique wear properties.

Multi-Functional Coatings: Combine khả năng chống mài mòn, corrosion resistance, and anti-sticking properties in one layer.

AI-Optimized Coating Processes: Machine learning to predict coating performance in specific conditions.

Environmentally Friendly Coatings: Cobalt-free binders and low-emission processes.

Những điểm chính cần ghi nhớ cho người ra quyết định

Coatings can double or triple the service life of carbide wear parts.

The right coating depends on the application’s heat, wear, and corrosion demands.

Investing in coated carbide often results in lower total cost of ownership.

Stay updated with coating innovations to maintain a competitive advantage.

Phần kết luận

In modern manufacturing, mining, and processing industries, the role of coatings in enhancing carbide wear performance cannot be ignored.

By reducing friction, resisting heat, and preventing corrosion, coatings help businesses save money, improve output quality, and minimize downtime.

Decision-makers who choose the right coating for their application will not only protect their investment but also improve operational efficiency.

In a competitive market, this can be the difference between meeting deadlines and losing contracts.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.