In the world of modern industry, performance and reliability are critical. Many companies depend on precision components that can handle high stress, heavy loads, and long service hours.

One such component is the tungsten carbide ball. Known for its strength, durability, and resistance to wear, these balls are used in bearings, van, flowmeters, grinding media, and many other high-demand applications.

This article explores why tungsten carbide balls are stronger and longer-lasting than steel or ceramic alternatives, what gives them their unique performance, and why companies across industries choose them.

What Are Tungsten Carbide Balls?

Tungsten carbide balls are spherical components made from a compound of tungsten and carbon. The material is extremely hard, ranking close to diamond on the độ cứng scale.

This hardness, combined with độ dẻo dai from a metallic binder (usually cobalt or nickel), makes the balls ideal for demanding industrial use.

They are produced in a wide range of diameters, from tiny precision balls for flowmeters to large balls for valves and heavy machinery. The balance of hardness and toughness is what sets them apart from regular steel balls.

Key Properties That Drive Strength

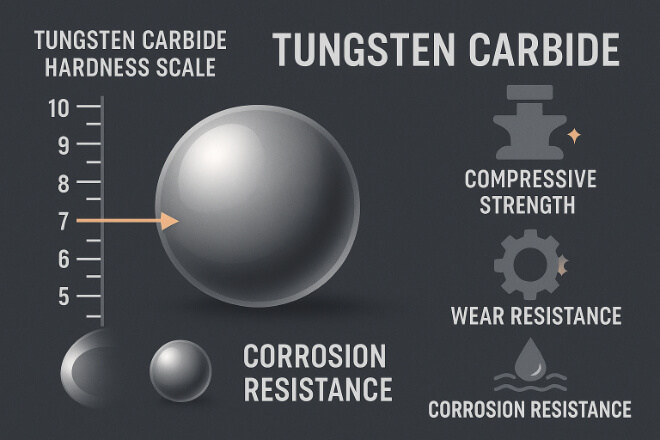

The strength of tungsten carbide balls comes from their microstructure. Several features make them stand out:

Cao Độ cứng – Second only to diamond, providing strong resistance against abrasion.

Compressive Strength – They can withstand massive loads without cracking.

Khả năng chống mài mòn – Designed to last longer under friction and contact pressure.

Khả năng chống ăn mòn – With the right binder and coatings, they resist rust and chemicals.

For companies, this means longer service life and lower replacement costs, especially in high-wear environments.

Why Durability Matters in Industry

Durability is not just a technical feature—it has direct business impact. When a bearing or valve fails, operations stop. Downtime can cost thousands or even millions in lost production.

Tungsten carbide balls reduce downtime by lasting far longer than alternatives.

While a steel ball may wear out quickly under high stress, tungsten carbide maintains its shape and performance for much longer.

For decision-makers, this translates into:

Lower operational costs

Less frequent replacements

More reliable performance

Better return on investment

Tungsten Carbide vs Steel Balls

Steel balls are cheaper and widely used, but they fall short in high-load or abrasive environments. Tungsten carbide balls, on the other hand:

Last up to 10x longer than steel.

Handle higher pressure without deformation.

Perform better in abrasive or corrosive conditions.

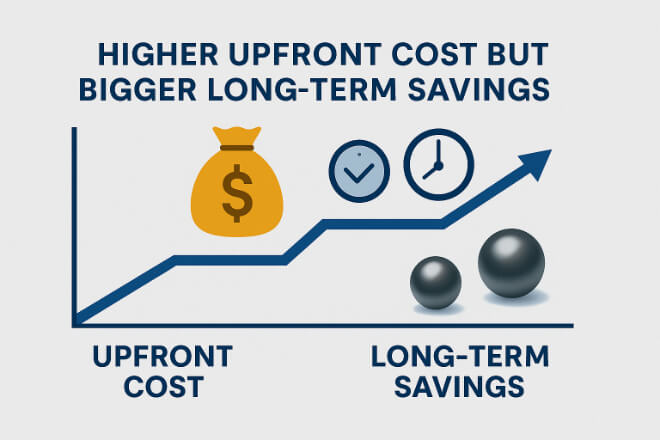

While the upfront cost is higher, the long-term savings and reliability make tungsten carbide the better choice for industries where performance matters.

Common Industrial Applications

Tungsten carbide balls are used across multiple industries because of their strength and durability. Some key examples include:

Bearings – For heavy-duty equipment, turbines, and automotive parts.

Valves – In dầu, khí đốt, and chemical industries where sealing under pressure is critical.

Flowmeters – To maintain accurate measurements in harsh environments.

Grinding Media – In mining, cement, and material processing plants.

Precision Instruments – Micrometers, gauges, and scientific tools.

In each case, the decision to use tungsten carbide balls is based on their ability to provide consistent performance under stress.

Chi phí so với Giá trị dài hạn

Some companies hesitate because tungsten carbide balls cost more upfront. However, when looking at the full lifecycle, they deliver better value.

Lower frequency of replacements → Fewer shutdowns.

Less wear on machinery → Longer equipment life.

Consistent performance → Higher product quality.

In industries where every hour of downtime is expensive, the durability of tungsten carbide pays for itself.

Tính bền vững và tái chế

Durability also supports sustainability. Longer life means fewer replacements, less waste, and lower material consumption.

Additionally, tungsten carbide balls can be recycled, reducing environmental impact.

Many suppliers offer recycling programs where worn carbide parts are collected, processed, and reused.

Những điểm chính cần ghi nhớ cho người ra quyết định

For company leaders and procurement managers, the choice of materials directly affects cost, efficiency, and reliability. Tungsten carbide balls offer:

Unmatched strength in high-load applications.

Proven durability that lowers downtime.

Better long-term ROI compared to steel.

A sustainable option through recycling.

When performance and reliability are non-negotiable, tungsten carbide is the smarter investment.

Phần kết luận

The strength and durability of tungsten carbide balls make them an essential choice for industries that demand precision, reliability, and cost savings over time.

From bearings to valves, flowmeters to grinding media, they consistently outperform steel and other alternatives.

For decision-makers, choosing tungsten carbide balls is not just a technical choice—it’s a business strategy for long-term efficiency and sustainability.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.