Bóng cacbua vonfram có kích thước nhỏ nhưng mang lại giá trị lớn trong nhiều ngành công nghiệp.

Được biết đến với sự cực đoan của họ độ cứng, cao khả năng chống mài mònvà khả năng làm việc dưới tải trọng nặng, chúng được lựa chọn thay vì bi thép khi hiệu suất và độ tin cậy là yếu tố quan trọng.

Đối với những người ra quyết định, việc hiểu rõ những quả bóng này được sử dụng ở đâu có thể giúp lập kế hoạch đầu tư tốt hơn và giảm chi phí dài hạn.

Bài viết này giải thích các ứng dụng hàng đầu của bi cacbua vonfram trong công nghiệp, cho thấy cách chúng hỗ trợ ổ trục, van, vít me bi, hoạt động mài, dầu khí công cụ và dụng cụ chính xác.

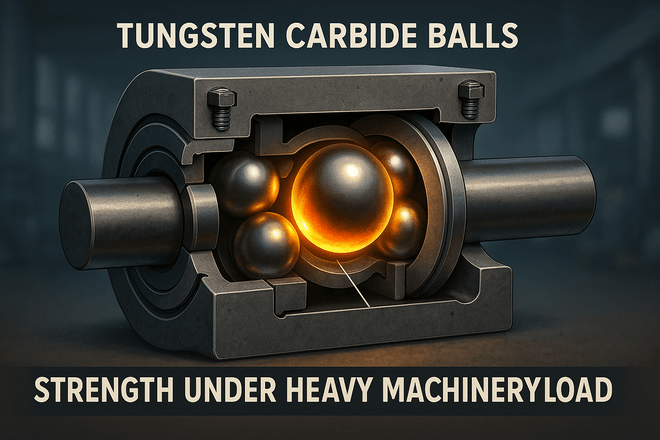

Vòng bi chịu tải nặng và tuổi thọ cao

Một trong những ứng dụng lớn nhất của bi cacbua vonfram là trong vòng bi.

Vòng bi có bi cacbua được sử dụng trong máy móc hạng nặng, hàng không vũ trụ, Và ô tô hệ thống.

Bởi vì của họ độ cứng và khả năng chịu đựng căng thẳng, những quả bóng này:

Bền hơn vòng bi thép

Giảm ma sát dưới áp suất cao

Giữ cho máy móc hoạt động trơn tru ngay cả trong điều kiện khắc nghiệt

Đối với những ngành công nghiệp mà thời gian ngừng hoạt động tốn kém, ổ bi cacbua là một khoản đầu tư thông minh.

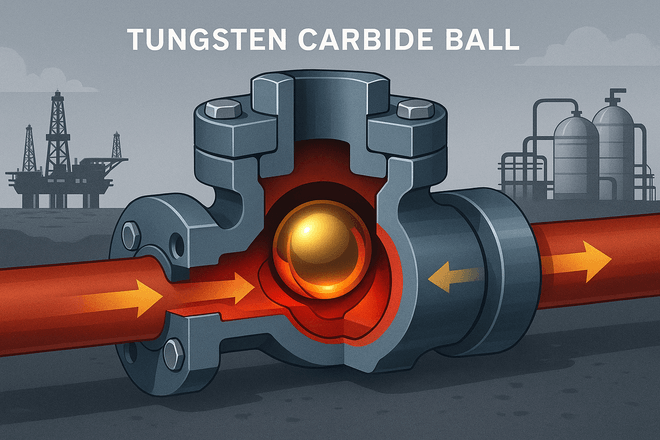

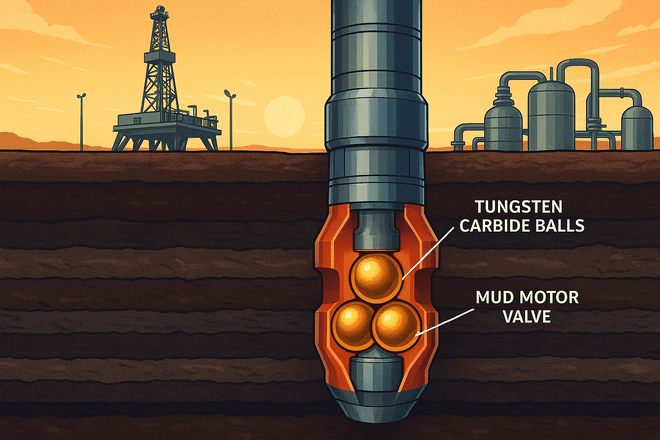

Van trong ngành dầu khí và hóa chất

Bi cacbua vonfram đóng vai trò quan trọng trong van công nghiệp. Trong dầu khí đường ống, nhà máy hóa chất và nhà máy phát điện, van phải được bịt kín để tránh rò rỉ.

Bi thép thường bị mòn nhanh, nhưng bi cacbua thì ngược lại:

Sự mài mòn từ cát, bùn và chất lỏng

Ăn mòn từ hóa chất và nước biển

Áp suất cao từ đường ống và hoạt động khoan

Điều này làm cho chúng trở nên quan trọng trong việc giảm thiểu bảo trì và cải thiện an toàn.

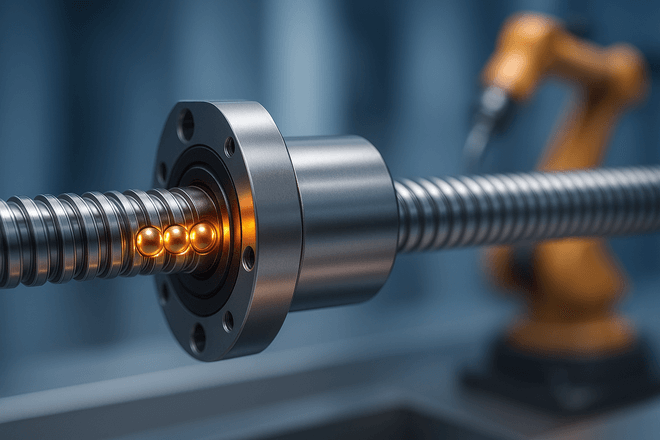

Vít me bi trong máy CNC và robot

Các thiết bị chính xác như máy CNC và hệ thống robot dựa vào trục vít me bi để chuyển động chính xác. Bi cacbua vonfram trong trục vít me bi mang lại:

Độ chính xác cao và di chuyển mượt mà

Ít hao mòn hơn khi hoạt động liên tục

Tuổi thọ dài hơn so với thép

Đối với các nhà sản xuất trong hàng không vũ trụ, thuộc về y học trong các thiết bị và ngành ô tô, vít me bi cacbua có độ chính xác cao hơn và năng suất cao hơn.

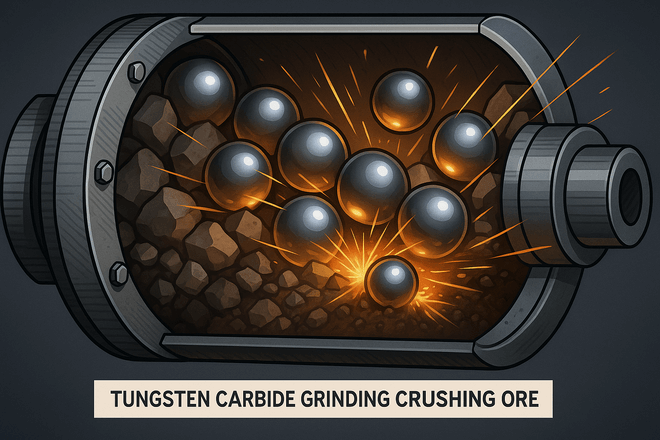

Vật liệu nghiền và xay

Bóng cacbua vonfram được sử dụng rộng rãi làm vật liệu nghiền và xay.

Chúng được đặt bên trong máy nghiền bi để nghiền nát các vật liệu cứng như khoáng chất, hợp kim và gốm sứ.

So với bi thép, chúng:

Cung cấp kết quả nghiền mịn hơn

Kéo dài thời gian trước khi thay thế

Giảm thiểu ô nhiễm vật liệu đã qua chế biến

Các ngành công nghiệp khai thác mỏ, xi măng và hóa chất phụ thuộc vào vật liệu nghiền cacbua để đạt hiệu quả và tiết kiệm chi phí.

Dụng cụ khoan dầu khí

Trong ngành dầu khí, bi cacbua được sử dụng trong các dụng cụ khoan và thiết bị khoan giếng.

Những dụng cụ này phải chịu được điều kiện khắc nghiệt như nhiệt độ cao, áp suất cao và chất lỏng mài mòn. Bi cacbua vonfram:

Cải thiện độ tin cậy của dụng cụ khi khoan sâu

Giảm thiểu sự mài mòn ở động cơ bùn và van khoan

Kéo dài tuổi thọ của thiết bị khai thác dầu khí có chi phí cao

Đối với các công ty dầu mỏ, điều này có nghĩa là ít xảy ra sự cố hơn và giảm thời gian ngừng hoạt động.

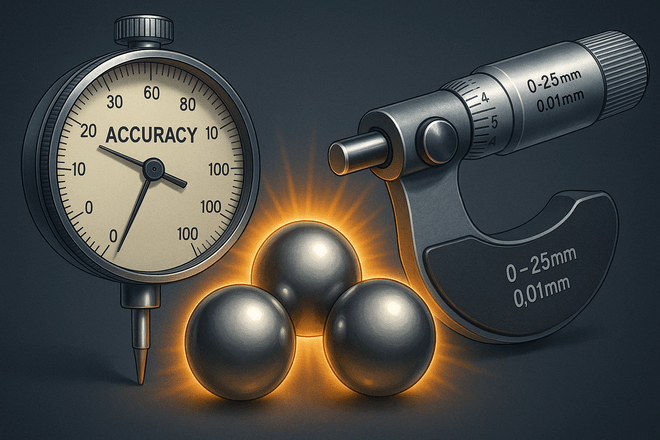

Thiết bị đo lường và dụng cụ chính xác

Bi cacbua cũng được sử dụng trong các dụng cụ chính xác như đồng hồ đo, dụng cụ đo lường và thiết bị y tế.

Độ cứng cực cao của chúng cho phép chúng giữ được hình dạng và độ chính xác trong thời gian rất dài. Các lợi ích bao gồm:

Hiệu chuẩn ổn định theo thời gian

Khả năng chống biến dạng

Độ chính xác cao trong các phép đo quan trọng

Điều này khiến chúng trở nên lý tưởng cho các ngành công nghiệp đòi hỏi độ chính xác cao.

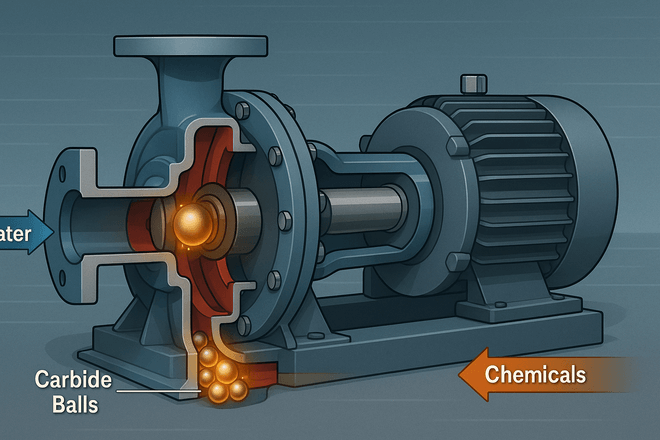

Máy bơm và hệ thống niêm phong

Trong máy bơm công nghiệp và hệ thống làm kín, bi cacbua vonfram giúp giảm rò rỉ và chịu được ma sát.

Chúng chống lại sự ăn mòn từ chất lỏng mài mòn và duy trì hiệu suất trơn tru khi vận hành liên tục.

Ứng dụng này phổ biến trong các ngành xử lý nước, hóa dầu và chế biến thực phẩm.

Bảng so sánh: Bi cacbua vonfram so với bi thép

| Tính năng | Bóng cacbua vonfram | Quả bóng thép |

|---|---|---|

| Độ cứng | Rất cao (90+ HRA) | Trung bình (~60 HRC) |

| Khả năng chống mài mòn | Tuyệt vời, tuổi thọ dài | Thấp hơn, mòn nhanh hơn |

| Khả năng chống ăn mòn | Chống lại hóa chất và nước biển | Yếu trước chất ăn mòn |

| Ứng dụng | Vòng bi, van, lưu lượng kế, dầu khí | Máy móc nói chung |

| Trị giá | Trả trước cao hơn | Thấp hơn ở phía trước |

Suy nghĩ cuối cùng

Bi cacbua vonfram là thành phần quan trọng trong nhiều ngành công nghiệp.

Từ ổ trục trong máy móc hạng nặng đến van trong dầu khí, từ vít me bi trong hệ thống CNC đến vật liệu mài trong khai thác mỏ, ứng dụng của chúng rất rộng rãi và thiết yếu.

Đối với những người ra quyết định, thông điệp rất rõ ràng: mặc dù bi cacbua có giá thành ban đầu cao hơn, nhưng chúng có tuổi thọ cao hơn, hiệu suất tốt hơn và chi phí thấp hơn trong dài hạn.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.