The oilfield and petrochemical industries run some of the most demanding systems in the world.

Pumps, compressors, valves, and drilling equipment must work under high pressure, heat, and corrosive fluids.

A failure in sealing systems can lead to downtime, safety risks, and financial loss. This is why many companies choose tungsten carbide seal rings.

This article explains how vòng đệm cacbua vonfram perform in oilfield and petrochemical applications, their unique properties, and why they are the best option for long-term reliability and cost savings.

Why Seal Rings Matter in Oilfield and Petrochemical Equipment

Seal rings are critical in protecting equipment against:

Leakage of dầu, khí đốt, or chemicals

Erosion from abrasive particles

Căng thẳng nhiệt từ nhiệt độ cao

Sốc cơ học từ những thay đổi áp suất đột ngột

A strong, durable seal material ensures safety, compliance, and efficiency in these harsh environments.

Tính chất của vòng đệm cacbua vonfram

Tungsten carbide is a material created by combining tungsten and carbon, bonded with cobalt or nickel. Its main properties include:

Vô cùng độ cứng – Prevents wear from friction and abrasives.

High compressive strength – Withstands heavy pressure loads.

Thermal stability – Works reliably in hot oil and gas systems.

Khả năng chống ăn mòn – Resists hydrocarbons, seawater, and chemicals.

Long service life – Reduces replacement frequency.

These features make tungsten carbide the preferred sealing material in drilling rigs, refineries, and petrochemical plants.

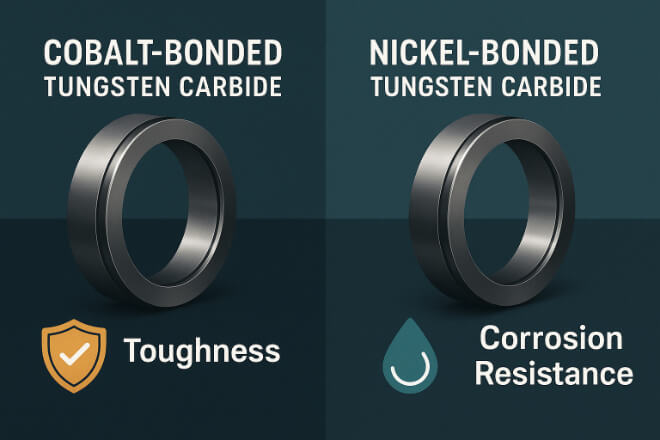

Cacbua vonfram liên kết coban so với liên kết niken

Binder choice affects performance:

1). Cacbua vonfram liên kết coban

Cao độ dẻo dai, good for vibration and shock.

Best in oilfield compressors and drilling pumps.

Vừa phải corrosion resistance.

2). Cacbua vonfram liên kết niken

Excellent resistance to corrosive chemicals.

Best for refineries and petrochemical plants.

Ít bền hơn so với liên kết bằng coban.

Decision-makers must match the grade to the specific operating environment.

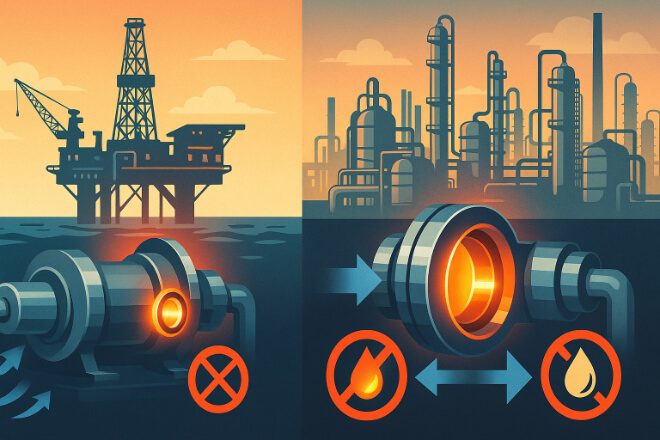

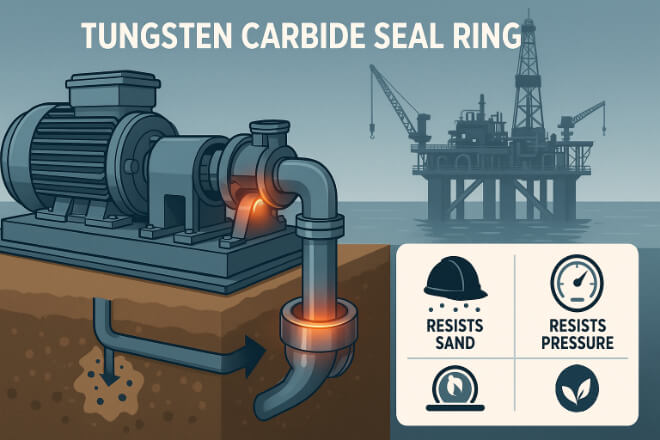

Performance in Oilfield Applications

In oilfield operations, seal rings face:

High-pressure crude dầu khí

Sand and abrasive particles in drilling fluids

Extreme temperature changes

Protect pumps and compressors from wear.

Prevent leakage that could cause safety issues.

Extend service life in drilling and production systems.

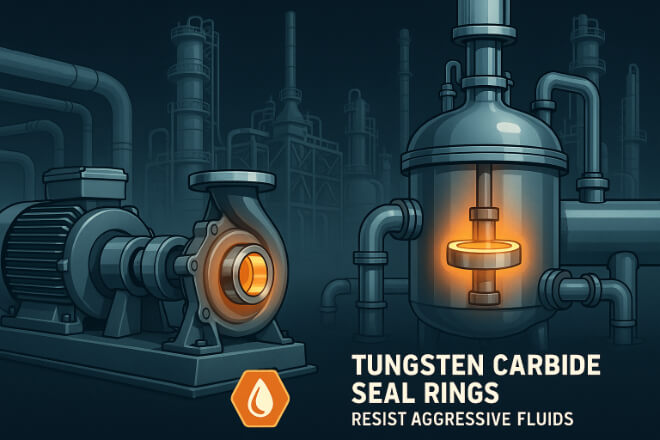

Performance in Petrochemical Applications

In petrochemical plants, seals face aggressive chemical exposure. Tungsten carbide seal rings:

Provide resistance against solvents, acids, and alkalis.

Work reliably in refinery pumps and chemical reactors.

Reduce downtime by lasting longer under corrosive conditions.

This makes them essential in facilities where chemical resistance is critical.

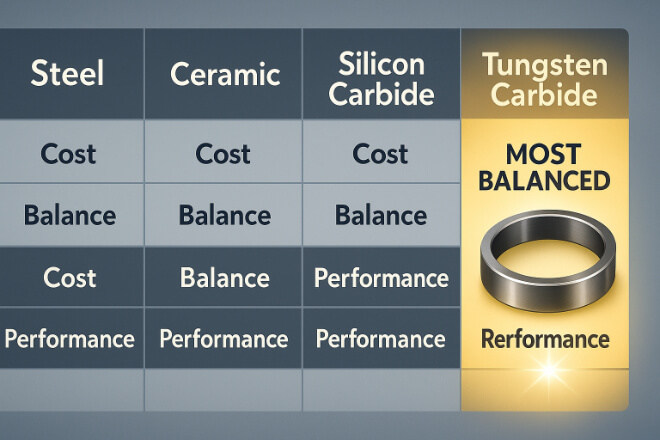

So sánh với các vật liệu niêm phong khác

Steel seals – Cheap but corrode quickly in oil and chemicals.

Ceramic seals – Chemically resistant but brittle under shock.

Silicon carbide – Strong against chemicals but less tough under impact.

Tungsten carbide – Best balance of strength, độ dẻo dai, and chemical resistance.

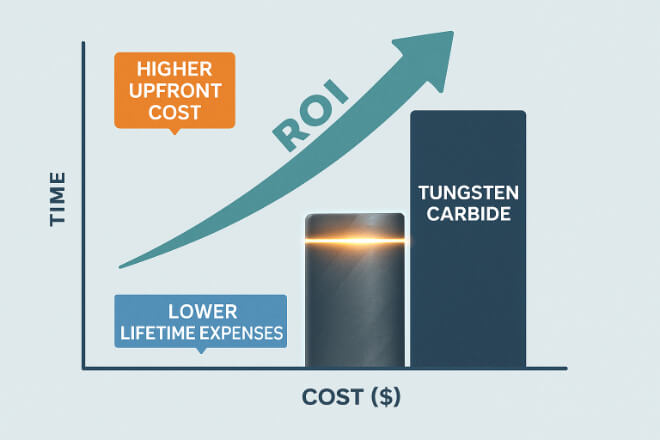

Chi phí so với Giá trị dài hạn

Although tungsten carbide seal rings have a higher initial cost, their life cycle benefits outweigh the price:

Ít thay thế hơn → Giảm chi phí phụ tùng thay thế.

Less downtime → Năng suất cao hơn.

Longer pump life → Reduced equipment damage.

ROI tốt hơn → Cơ sở tài chính vững chắc cho người ra quyết định.

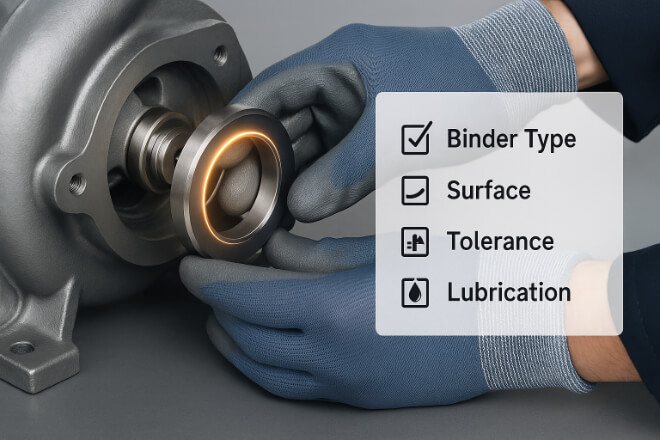

Thực hành tốt nhất để sử dụng vòng đệm cacbua vonfram

To ensure maximum performance in oilfield and petrochemical systems:

Choose the right grade → Niken chống ăn mòn, coban chống sốc.

Cài đặt cẩn thận → Avoid scratches that weaken chemical resistance.

Kiểm tra thường xuyên → Phát hiện sớm các dấu hiệu hao mòn hoặc ăn mòn.

Duy trì bôi trơn → Reduces heat and friction damage.

Tính bền vững và tái chế

Tungsten carbide seal rings are recyclable. Many suppliers reclaim used rings and process them into new products.

This reduces waste and supports environmental goals, which is increasingly important in oil and petrochemical industries.

Những điểm chính cần ghi nhớ cho người ra quyết định

Tungsten carbide seal rings are best for oilfield and petrochemical equipment.

They resist wear, pressure, heat, and corrosion.

Cobalt-bonded grades suit heavy loads and shock.

Nickel-bonded grades suit chemical-rich environments.

Higher upfront cost is offset by longer service life and fewer failures.

Phần kết luận

For oilfield and petrochemical applications, tungsten carbide seal rings are the most reliable choice. They handle harsh conditions, corrosive fluids, and heavy loads better than most alternatives.

For decision-makers, investing in tungsten carbide seal rings means safer operations, less downtime, and stronger long-term value.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.