Trong máy bơm, máy nén, tua bin và thiết bị hàng hải, vòng đệm kín rất quan trọng để ngăn ngừa rò rỉ và bảo vệ máy móc.

Việc lựa chọn vật liệu phù hợp cho vòng đệm kín có tác động trực tiếp đến tuổi thọ, độ tin cậy và chi phí bảo trì thiết bị. Hai trong số những vật liệu được sử dụng phổ biến nhất là cacbua vonfram và gốm.

Cả hai vật liệu đều có những ưu điểm vượt trội, nhưng chúng không giống nhau. Bài viết này cung cấp so sánh chi tiết giữa vòng đệm cacbua vonfram và vòng đệm gốm, tập trung vào đặc tính, hiệu suất và ứng dụng của chúng.

Vòng đệm cacbua vonfram là gì?

Cacbua vonfram là hợp chất của vonfram và cacbon, liên kết với coban hoặc niken. Nó được sử dụng rộng rãi trong phớt cơ khí vì:

Vô cùng độ cứng → Chống mài mòn do ma sát và chất lỏng mài mòn.

Cường độ nén cao → Khả năng chịu tải trọng áp lực lớn.

Độ ổn định nhiệt → Độ tin cậy ở nhiệt độ hoạt động cao.

Khả năng chống ăn mòn → Bảo vệ mạnh mẽ trong dầu, khí đốt, nước biển và hóa chất.

Độ bền → Tuổi thọ cao, giảm thiểu việc thay thế.

Vòng đệm gốm là gì?

Vòng đệm gốm được làm từ các vật liệu như nhôm oxit hoặc silicon carbide. Chúng được biết đến với các đặc tính sau:

Mạnh khả năng chống ăn mòn → Hiệu suất tuyệt vời trong môi trường giàu hóa chất.

Nhẹ → Thấp hơn Tỉ trọng so với kim loại.

Khả năng chịu nhiệt → Độ ổn định trong ứng dụng nóng.

Chi phí thấp → Nói chung rẻ hơn cacbua vonfram.

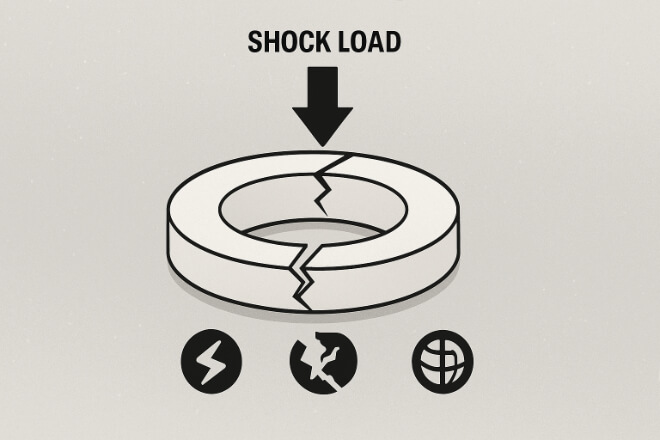

Tuy nhiên, gốm sứ giòn hơn, khiến chúng ít chịu được va đập hoặc rung động.

Điểm mạnh của vòng đệm cacbua vonfram

Thượng đẳng độ dẻo dai – Ít giòn hơn, có thể chịu được va đập và rung động.

Tuổi thọ dài hơn – Đặc biệt trong các ứng dụng mài mòn hoặc áp suất cao.

Tốt hơn khả năng chống mài mòn – Lý tưởng cho máy bơm bùn và thiết bị khai thác dầu khí.

Khả năng tái chế – Cacbua vonfram có thể được thu gom và tái sử dụng.

Điểm yếu của vòng đệm cacbua vonfram

Vật liệu nặng hơn – Cao hơn Tỉ trọng làm tăng trọng lượng cho thiết bị.

Chi phí trả trước cao hơn – Đắt hơn so với các lựa chọn thay thế bằng gốm.

Các loại liên kết coban – Ít hơn chống ăn mòn trong nước biển so với gốm sứ.

Điểm mạnh của vòng đệm gốm

Khả năng chống hóa chất tuyệt vời – Hiệu suất mạnh mẽ chống lại axit và kiềm.

Thiết kế nhẹ – Hữu ích trong các hệ thống mà trọng lượng là yếu tố quan trọng.

Chi phí thấp hơn – Đầu tư ban đầu rẻ hơn so với cacbua vonfram.

Vật liệu phi kim loại – Thích hợp cho các ứng dụng nhạy cảm với điện.

Điểm yếu của vòng đệm gốm

Tính chất giòn – Dễ bị nứt khi chịu tác động cơ học hoặc rung động.

Thấp hơn độ dẻo dai – Không thể xử lý được các mức áp suất đột ngột.

Tuổi thọ ngắn hơn trong chất lỏng mài mòn – Mòn nhanh hơn trong môi trường bùn hoặc chứa đầy cát.

So sánh song song

| Tính năng | Vòng đệm cacbua vonfram | Vòng đệm gốm |

|---|---|---|

| Khả năng chống mài mòn | Tuyệt vời, xử lý tốt các chất mài mòn | Trung bình, yếu hơn trong bùn |

| Khả năng chống ăn mòn | Chất lượng tốt, liên kết niken vượt trội | Tuyệt vời, đặc biệt là trong axit |

| Độ dẻo dai | Cao, chống sốc và rung động | Thấp, giòn khi va chạm |

| Tuổi thọ | Bền lâu trong điều kiện khắc nghiệt | Ngắn hơn trong hệ thống mài mòn |

| Trị giá | Đầu tư ban đầu cao hơn | Chi phí ban đầu thấp hơn |

| Khả năng tái chế | Có, có thể tái chế | Khả năng tái chế hạn chế |

Ứng dụng của vòng đệm cacbua vonfram

Dầu khí máy bơm → Chịu được áp suất, chất mài mòn và hydrocarbon.

Tua bin phát điện → Xử lý chu kỳ nhiệt và ứng suất.

Hệ thống đẩy tàu biển → Chống rung và nước biển.

Nhà máy hóa chất → Hoạt động tốt trong chất lỏng có tính ăn mòn khi có chất kết dính phù hợp.

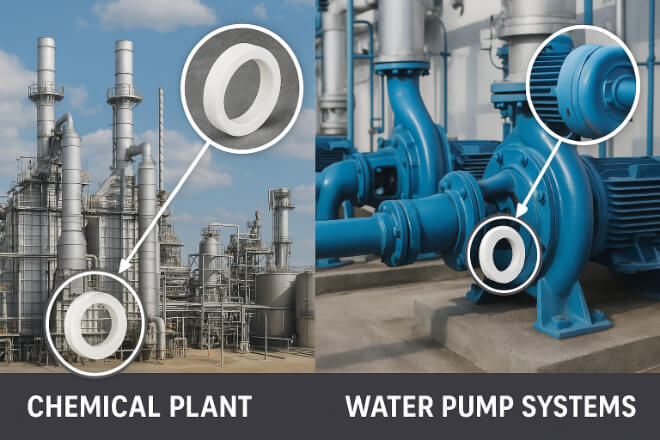

Ứng dụng của vòng đệm gốm

Xử lý hóa học → Chống lại axit và kiềm.

Máy bơm nước → Tiết kiệm chi phí trong điều kiện ít mài mòn.

Ngành công nghiệp điện tử → Thích hợp cho các ứng dụng bịt kín phi kim loại.

Hệ thống hàng hải hạng nhẹ → Làm việc trong môi trường nước biển có độ rung thấp.

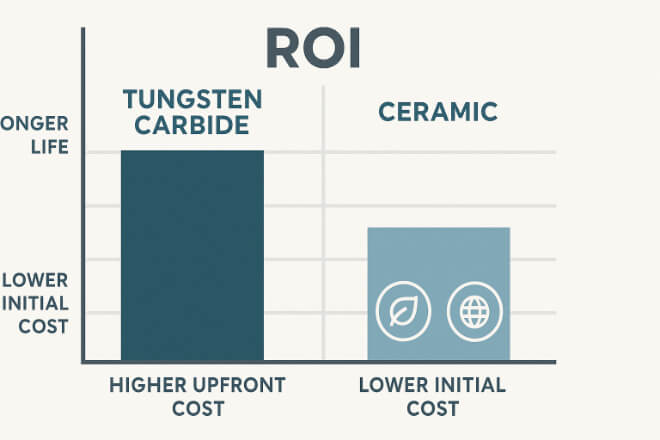

Chi phí so với Giá trị dài hạn

Cacbua vonfram → Chi phí mua cao hơn nhưng tuổi thọ dài hơn và ít phải thay thế hơn → ROI tốt hơn.

Gốm sứ → Chi phí mua thấp hơn nhưng tuổi thọ ngắn hơn trong các hệ thống mài mòn hoặc chịu va đập mạnh → chi phí bảo trì cao hơn.

Đối với những người ra quyết định, sự lựa chọn thường phụ thuộc vào khả năng tiết kiệm chi phí lâu dài chứ không chỉ là giá ban đầu.

Những điểm chính cần ghi nhớ cho người ra quyết định

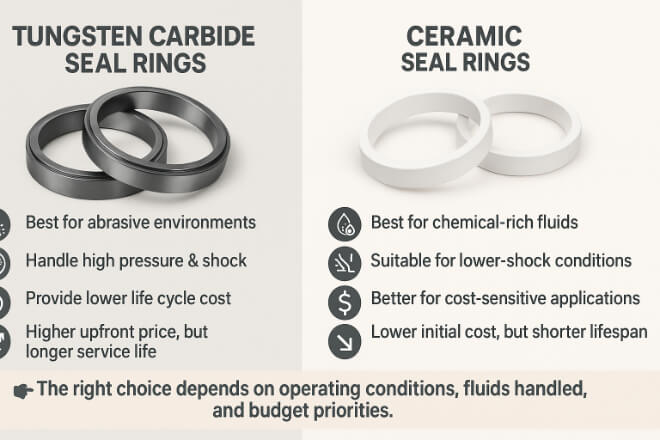

Vòng đệm cacbua vonfram phù hợp nhất với môi trường mài mòn, áp suất cao và va đập mạnh.

Vòng đệm gốm phù hợp nhất với môi trường giàu hóa chất, ít va chạm và nhạy cảm về chi phí.

Sự lựa chọn phụ thuộc vào điều kiện vận hành, chất lỏng được xử lý và ưu tiên ngân sách.

Trong nhiều trường hợp, cacbua vonfram có chi phí vòng đời thấp hơn, ngay cả khi giá ban đầu cao hơn.

Phần kết luận

Cả vòng đệm cacbua vonfram và vòng đệm gốm đều đóng vai trò quan trọng trong hệ thống đệm kín công nghiệp.

Cacbua vonfram mang lại độ bền, khả năng chống mài mòn và độ bền trong môi trường khắc nghiệt, trong khi gốm sứ có khả năng chống hóa chất tuyệt vời và tiết kiệm chi phí.

Đối với người ra quyết định, sự lựa chọn đúng đắn phụ thuộc vào điều kiện hoạt động cụ thể.

Trong các hệ thống mài mòn, áp suất cao, cacbua vonfram thường là lựa chọn tốt hơn. Trong môi trường hóa chất ít va đập, phớt gốm có thể là lựa chọn phù hợp.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.