Trong các ngành công nghiệp như sự thi công, manufacturing, and gia công kim loại, cutting rebar and wire accurately and efficiently is crucial.

The cutting tools used must withstand constant wear and high-impact forces. Tungsten carbide tips are often the best choice for these applications due to their outstanding impact resistance, durability, and khả năng chống mài mòn.

In this blog, we will explore the benefits of using tungsten carbide tips for rebar and wire cutting, and how they contribute to improving performance and extending tool life in harsh environments.

Why Tungsten Carbide Tips Are Ideal for Rebar and Wire Cutting

Rebar and wire cutting can be challenging due to the hardness and toughness of the materials involved.

Tungsten carbide tips are designed to handle these challenges effectively, providing long-lasting performance under demanding conditions.

1). Cao cấp Độ cứng

Tungsten carbide is one of the hardest materials available, which makes it an ideal choice for cutting through tough materials like rebar and wire.

Its hardness ensures that tungsten carbide tips maintain sharpness over time, enabling precise cuts without the need for frequent tool changes.

2). Impact Resistance

Rebar and wire cutting often involve high-impact forces, which can cause traditional cutting tools to break or wear down quickly.

Tungsten carbide tips are highly resistant to impact, meaning they can withstand the stresses of cutting through these tough materials without chipping or cracking.

This impact resistance is key to maintaining consistent performance in demanding applications.

Due to the abrasive nature of rebar and wire, cutting tools are subjected to significant wear.

Tungsten carbide tips resist wear much better than many other materials, allowing them to perform efficiently over extended periods.

The wear resistance of carbide tips reduces the need for frequent tool replacements and helps keep production costs down.

Performance Benefits of Tungsten Carbide Tips in Rebar and Wire Cutting

Using tungsten carbide tips for rebar and wire cutting offers numerous performance benefits that directly enhance productivity and cost efficiency in various industries.

1). Enhanced Cutting Precision

Tungsten carbide tips retain their sharp cutting edges for longer periods, which ensures cleaner and more precise cuts.

This precision is critical in applications where rebar and wire must be cut to specific lengths or sizes for construction and manufacturing purposes.

The consistent performance of tungsten carbide tips results in fewer mistakes, better quality control, and reduced waste.

2). Longer Tool Life

Các độ cứng, impact resistance, and khả năng chống mài mòn of tungsten carbide tips significantly extend their lifespan.

These tips are less likely to become dull or damaged during rebar and wire cutting, allowing manufacturers to use the same tools for longer periods.

This longer tool life results in fewer tool changes, which helps reduce downtime and improve overall efficiency.

3). Reduced Operational Costs

While tungsten carbide tips may have a higher upfront cost compared to other materials, their durability and longer tool life result in long-term savings.

Fewer tool replacements and reduced maintenance costs lead to overall lower operational expenses, making tungsten carbide tips a cost-effective solution for high-volume rebar and wire cutting applications.

Applications of Tungsten Carbide Tips in Rebar and Wire Cutting

Tungsten carbide tips are used in various tools for rebar and wire cutting, each designed to meet the specific demands of the job. These tips provide reliable performance in several key applications:

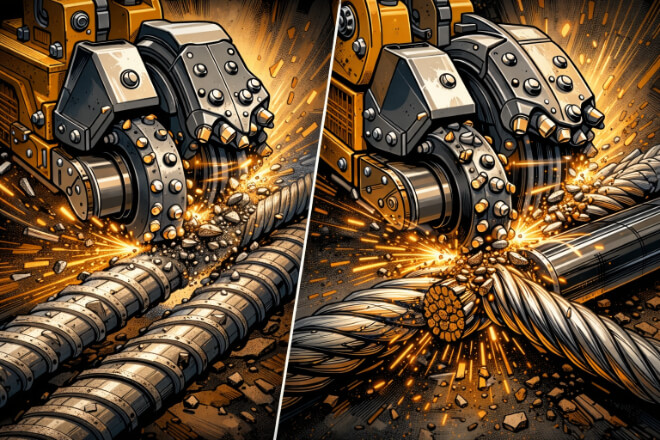

1). Rebar Cutting

Rebar is commonly used in construction to reinforce concrete, and cutting it requires strong, durable tools.

Tungsten carbide tips are used in rebar cutters, which are designed to cut through steel bars with minimal effort.

The wear and impact resistance of tungsten carbide ensure that these tools maintain their cutting effectiveness over time, even when cutting through tough rebar.

2). Wire Cutting

Wire cutting is a common task in industries such as electrical manufacturing, metalworking, and construction.

Tungsten carbide tips are used in wire cutters and other cutting tools to provide precise cuts on wire materials such as steel, copper, and aluminum.

The sharpness and durability of carbide tips ensure that wire cutting tools continue to perform efficiently, even in high-demand operations.

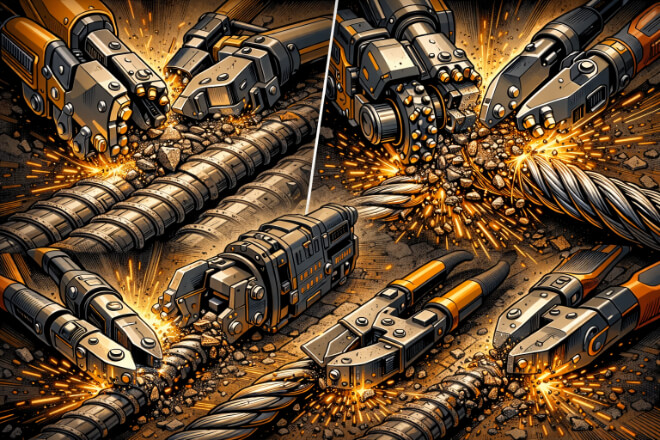

3). Industrial Cutting Tools

Tungsten carbide tips are also used in various industrial cutting tools, such as shears, saws, and grinding machines.

These tools are used in applications that involve cutting through tough materials, and carbide tips ensure that the tools maintain their cutting edges and performance for longer periods, even under harsh conditions.

Maximizing the Performance of Tungsten Carbide Tips in Cutting Tools

To get the most out of tungsten carbide tips, it’s essential to maintain and optimize their use in rebar and wire cutting applications. Here are some best practices to maximize performance:

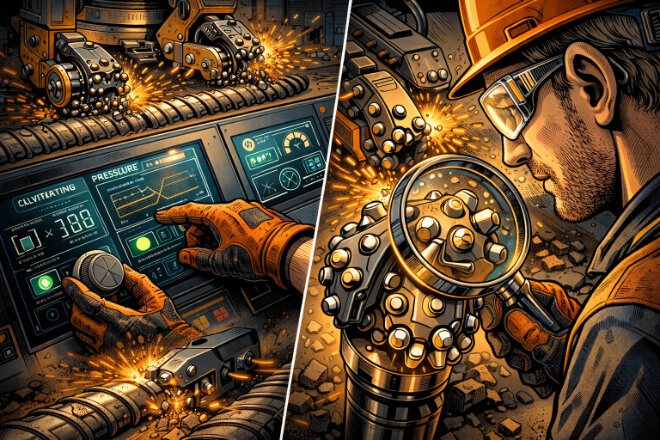

1). Adjusting Cutting Parameters

The cutting speed, feed rate, and pressure applied to the material should be optimized for the specific type of material being cut.

Tungsten carbide tips perform best when used within the recommended cutting parameters, as this reduces unnecessary wear and ensures that the tips stay sharp and effective for longer.

2). Routine Maintenance and Inspections

Regular maintenance and inspections are crucial to extending the lifespan of carbide-tipped tools.

Checking for wear and tear, cracks, or damage will help identify when the tools need reconditioning or replacement.

Preventive maintenance ensures that the tips continue to function at their best, reducing downtime and increasing productivity.

3). Proper Storage and Handling

Tungsten carbide tips should be handled and stored properly to avoid unnecessary damage. Storing tools in a dry, clean environment will prevent corrosion and prolong their useful life.

Proper handling, such as avoiding dropping the tools or using them for unintended purposes, will also prevent damage and ensure consistent performance.

Cost-Efficiency of Tungsten Carbide Tips in Rebar and Wire Cutting

Trong khi tungsten carbide tips are often more expensive than tools made from other materials, their long-term benefits make them a cost-effective solution for rebar and wire cutting.

1). Lower Maintenance and Replacement Costs

Because tungsten carbide tips last longer and perform more efficiently, companies spend less money on tool replacements and maintenance.

This reduces overall operational costs and contributes to more predictable budgets.

2). Fewer Downtime and Increased Productivity

The durability of tungsten carbide tips ensures that cutting operations experience less downtime due to tool replacements or failures.

With fewer interruptions, production is more consistent and efficient, helping companies meet deadlines and improve throughput.

3). Return on Investment (ROI)

The extended life, efficiency, and reduced operational costs associated with tungsten carbide tips contribute to a strong return on investment.

Over time, the initial higher cost of carbide tips is offset by the savings on tool replacements, maintenance, and production costs.

Phần kết luận

Tungsten carbide tips are essential for rebar and wire cutting due to their superior hardness, wear resistance, and impact toughness.

These tips provide significant benefits, such as extended tool life, enhanced cutting efficiency, and reduced downtime, all of which contribute to a more cost-effective production process.

By using tungsten carbide tips, businesses can improve their operations, lower costs, and increase productivity, making them an excellent investment for industries that rely on cutting tools for high-demand applications.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.