When sourcing custom ống lót cacbua vonfram, two terms often decide whether your project runs smoothly or faces costly delays: MOQ (Minimum Order Quantity) and lead time.

For many decision-makers, these factors directly affect production schedules, procurement costs, and inventory strategies.

Understanding how MOQ and lead time are set — and how to manage them effectively — can save both time and money.

Tungsten carbide bushings are not standard parts. They are custom-engineered to fit specific shafts, housings, or operational environments.

Because of this, each batch requires tailored production, from powder preparation to sintering, grinding, and inspection.

This article explains what MOQ and lead time mean in the tungsten carbide manufacturing process, what affects them, and how to optimize your sourcing strategy for cost efficiency and reliability.

What Is MOQ and Why It Exists

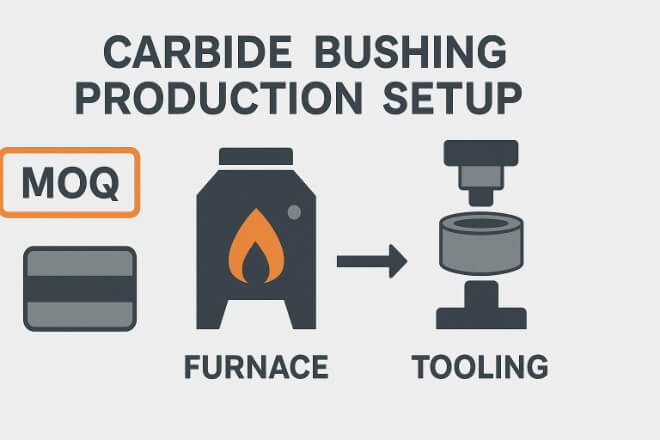

MOQ (Minimum Order Quantity) represents the smallest production batch a supplier is willing to manufacture or sell.

It ensures that the production setup and tooling costs are covered, while keeping operations efficient.

For custom ống lót cacbua vonfram, MOQ is usually 10 to 50 pieces, depending on size, tolerance, and shape complexity.

Suppliers need to maintain this minimum because of:

Tooling preparation: Every design requires molds and dies.

Sintering furnace loading: Carbide parts must be fired in batches to use energy efficiently.

Inspection time: Each piece needs dimensional and surface finish checks.

Inventory and raw material waste: Small orders often lead to unused powder or binder.

In short, MOQ protects the supplier’s production efficiency and ensures the customer receives consistent quality at a reasonable cost.

Typical MOQ Ranges by Application

The MOQ for tungsten carbide bushings can vary widely depending on the application type and part size.

| Ứng dụng | Part Type | Approximate MOQ | Notes |

|---|---|---|---|

| Pump and Compressor Bushings | Cylindrical or flanged | 20–30 pcs | Standard industrial grade, moderate complexity |

| Chemical and Marine Bushings | Nickel-binder types | 15–20 pcs | Lower batch size, higher cost per unit |

| Customized OEM Projects | Special geometry | 30–50 pcs | Includes setup and tooling investment |

If you only need a few prototypes, many manufacturers can still help — but the unit cost will be much higher, as setup costs are distributed over fewer parts.

Understanding Lead Time

Lead time refers to how long it takes for the supplier to produce and deliver your order after confirmation.

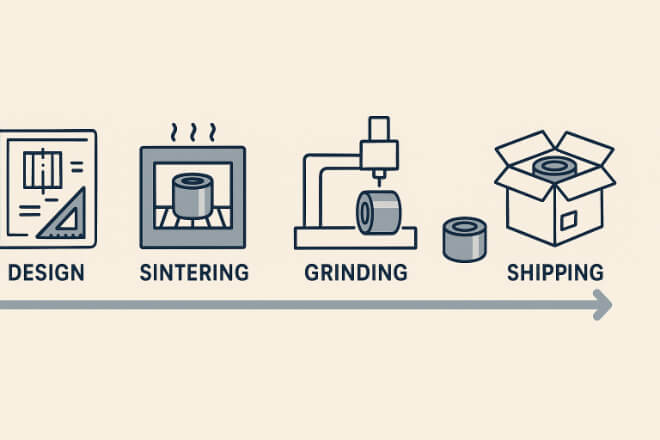

For tungsten carbide bushings, this period includes several steps:

Design and drawing review (1–3 days)

Raw material preparation and pressing (3–5 days)

Sintering process (5–7 days)

Grinding, lapping, and inspection (7–10 days)

Packaging and shipping (2–3 days)

In total, typical lead times range from 3 to 6 weeks for custom bushings — depending on size, tolerance, and supplier workload.

Lead time is not just about production; it’s also influenced by material stock, factory capacity, and testing requirements.

Factors That Affect MOQ and Lead Time

Several variables influence MOQ and lead time. Understanding them helps procurement teams plan better and negotiate smarter.

1). Part Complexity

Intricate geometries or tight tolerances require special tools and longer machining cycles.

2). Material Type

Cobalt-bonded grades are common and faster to produce, while nickel-bonded ones (used for corrosive media) take longer due to extra sintering steps.

3). Surface Finish Requirements

Mirror-lapped bushings (Ra ≤ 0.05 µm) require additional grinding and polishing time.

4). Quantity Ordered

Larger orders take more time but usually reduce cost per unit due to production efficiency.

5). Supplier’s Production Capacity

A fully booked supplier may have to queue your order, especially for high-volume clients.

How to Reduce Lead Time Without Sacrificing Quality

Decision-makers often want faster delivery — but rushing production risks quality issues.

Here are practical ways to optimize lead time without compromising performance:

Use standard sizes or geometries where possible.

Confirm drawings early to avoid approval delays.

Choose a supplier with in-house sintering and grinding.

Order in advance if your project has critical deadlines.

Establish repeat contracts for predictable demand, allowing the supplier to prepare in advance.

This proactive approach turns your supplier into a partner, not just a vendor.

Balancing MOQ and Cost Efficiency

The relationship between MOQ and price is simple: larger orders reduce the cost per unit. But ordering too many can tie up cash and storage space.

The ideal MOQ is where production efficiency and inventory cost meet in balance.

This is especially important for custom carbide bushings, which have a long shelf life but require careful handling.

| Order Quantity | Setup Cost per Unit | Unit Price | Overall Cost Efficiency |

|---|---|---|---|

| 10 pcs | Cao | $90 | Thấp |

| 25 pcs | Trung bình | $65 | Vừa phải |

| 50 pcs | Thấp | $50 | Cao |

For most industrial buyers, ordering 25–50 bushings per batch provides the best cost-performance ratio.

(Prices are fictitious, if you want to get the exact price, please liên hệ với chúng tôi!)

Negotiating MOQ and Lead Time With Suppliers

If your project has tight budgets or delivery schedules, negotiation is key.

Here’s how to approach it effectively:

Be transparent about your demand pattern: If your usage is regular, suppliers may lower MOQ.

Offer long-term agreements: Multi-order commitments encourage suppliers to plan materials in advance.

Consolidate different sizes in one batch: This can help reach the minimum required production volume.

Discuss safety stock or consignment options: Reliable suppliers often keep buffer inventory for trusted clients.

Avoid last-minute design changes: Modifications after tooling is set can delay the schedule by weeks.

Negotiation is not just about price — it’s about building trust and efficiency.

Working With Suppliers Who Offer Flexibility

Not all suppliers are equal. Some focus on large-scale OEM production, while others specialize in small-batch precision components.

If your demand varies, look for suppliers that offer:

Flexible MOQ policies

Fast prototyping services

In-house tooling and CNC grinding

Stable raw material stock

Short communication channels between sales, engineering, and production

Such suppliers help you reduce risks when your production volume changes unexpectedly.

Phần kết luận

MOQ and lead time are more than just numbers — they define how efficiently your supply chain operates.

By understanding these factors and building transparent relationships with trusted suppliers, you can secure stable pricing, fast delivery, and consistent quality.

A well-chosen tungsten carbide bushing partner can help balance cost, lead time, and reliability — giving your company a competitive advantage in both performance and delivery.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.