Sản xuất hiện đại đòi hỏi tốc độ, độ chính xác và độ bền.

Trong các ngành công nghiệp từ hàng không vũ trụ ĐẾN ô tô, các công ty cần các công cụ và thành phần có thể xử lý các điều kiện khắc nghiệt trong khi vẫn kiểm soát được chi phí.

Cacbua vonfram đã trở thành một trong những vật liệu quan trọng nhất để đạt được những mục tiêu này.

Được biết đến với sự đặc biệt của nó độ cứng Và khả năng chống mài mòn, cacbua vonfram được sử dụng rộng rãi trong dụng cụ cắt, các bộ phận hao mònvà thiết bị công nghiệp.

Bài viết này giải thích cacbua vonfram là gì, cách thức hoạt động, nơi sử dụng và lý do tại sao nó rất quan trọng đối với sản xuất hiện đại.

Cacbua Vonfram là gì?

Cacbua vonfram (WC) là hợp chất được tạo thành từ các nguyên tử vonfram và cacbon, liên kết với nhau để tạo thành vật liệu cứng và đặc.

Nó thường được kết hợp với một lượng nhỏ coban hoặc niken làm chất kết dính. Sự kết hợp này tạo ra một vật liệu:

Cứng gấp đôi thép

Rất cứng (gần giống kim cương trên độ cứng tỉ lệ)

Khả năng chống mài mòn và chịu nhiệt cao

Nhờ những đặc tính này, cacbua vonfram là lựa chọn ưu tiên cho các công cụ và linh kiện sản xuất hiệu suất cao.

Tại sao cacbua vonfram lại quan trọng trong sản xuất

Trong sản xuất, thời gian chết và hiệu suất dụng cụ kém gây tốn kém chi phí. Vonfram cacbua mang lại những lợi ích trực tiếp cải thiện năng suất và lợi nhuận:

Tuổi thọ dụng cụ dài hơn – Dụng cụ có tuổi thọ dài hơn nhiều so với thép tốc độ cao (HSS) hoặc các vật liệu dụng cụ khác.

Sản xuất nhanh hơn – Tốc độ cắt cao hơn giúp giảm thời gian chu kỳ.

Độ chính xác tốt hơn – Giữ cho cạnh sắc nét trong thời gian dài, đảm bảo chất lượng đồng nhất.

Chi phí thấp hơn cho mỗi bộ phận – Ít thay đổi công cụ và ít phế liệu hơn.

Ứng dụng chính của cacbua vonfram trong sản xuất

| Ứng dụng | Ví dụ về công cụ hoặc thành phần | Lợi ích chính |

|---|---|---|

| Cắt kim loại | Chèn tiện, dao phay, mũi khoan | Tốc độ và độ chính xác cao |

| Hình thành và Định hình | Chết, đấm | Khả năng chống biến dạng |

| Khai thác và khoan | Mũi khoan, mũi cắt | Khả năng chống va đập và mài mòn |

| Các bộ phận hao mòn | Ghế van, ống lót | Chống ăn mòn và mài mòn |

Cacbua Vonfram so với các vật liệu dụng cụ khác

| Tài sản | Cacbua Vonfram | Thép tốc độ cao (HSS) | Đồ gốm |

|---|---|---|---|

| Độ cứng | Rất cao | Trung bình | Rất cao |

| Độ dẻo dai | Cao | Cao | Thấp |

| Khả năng chịu nhiệt | Cao | Trung bình | Cao |

| Tuổi thọ công cụ | Dài | Ngắn | Trung bình |

Lợi ích cho người ra quyết định

Đối với các nhà quản lý và đội ngũ mua sắm, lợi ích của cacbua vonfram không chỉ dừng lại ở hiệu suất kỹ thuật. Việc sử dụng các công cụ và linh kiện WC có thể:

Cải thiện ROI – Ngay cả khi chi phí trả trước cao hơn, lợi ích tiết kiệm được từ tuổi thọ dụng cụ dài hơn và chu kỳ nhanh hơn thường lớn hơn chi phí bỏ ra.

Nâng cao chất lượng sản phẩm – Hiệu suất ổn định giúp giảm thiểu sản phẩm lỗi và sản phẩm phải làm lại.

Giảm nhu cầu tồn kho – Ít sản phẩm thay thế có nghĩa là mức tồn kho thấp hơn.

Hỗ trợ các mục tiêu bền vững – Vonfram cacbua có thể được tái chế.

Các loại phổ biến và công dụng của chúng

| Cấp | Nội dung chất kết dính | Tốt nhất cho |

|---|---|---|

| WC hạt mịn | 6–8% Coban | Hoàn thiện các hoạt động, công cụ nhỏ |

| WC hạt trung bình | 8–10% Coban | Gia công chung |

| WC hạt thô | 10–15% Coban | Cắt nặng, cắt gián đoạn |

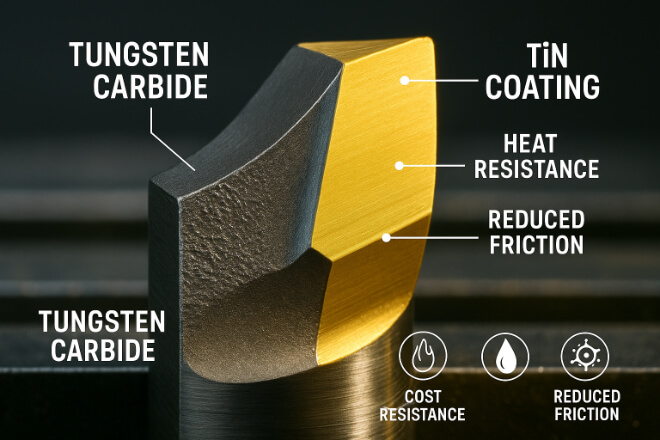

Lớp phủ cho dụng cụ cacbua vonfram

Nhiều dụng cụ cacbua vonfram được phủ các vật liệu như TiN, TiAlN hoặc kim cương để cải thiện hiệu suất hơn nữa. Các lớp phủ này có thể:

Giảm ma sát

Cải thiện khả năng chịu nhiệt

Kéo dài tuổi thọ dụng cụ

Cho phép gia công khô trong một số trường hợp

Cân nhắc về chi phí

Dụng cụ cacbua vonfram có giá cao hơn dụng cụ HSS, nhưng tuổi thọ dài hơn và hiệu quả cao hơn thường giúp chúng tiết kiệm chi phí hơn về lâu dài.

Khi đánh giá chi phí, người ra quyết định nên cân nhắc:

Chi phí cho mỗi bộ phận thay vì chỉ giá mua

Tiết kiệm chi phí bảo trì và thời gian chết

Tín dụng tái chế từ các công cụ cacbua được trả lại

Tính bền vững và tái chế

Cacbua vonfram có thể tái chế 100%. Nhiều nhà cung cấp có chương trình mua lại dụng cụ đã qua sử dụng.

Cacbua vonfram tái chế có thể được chế tạo thành các công cụ mới mà không làm giảm chất lượng, giúp giảm tác động đến môi trường và chi phí vật liệu.

Lựa chọn giải pháp cacbua vonfram phù hợp

Khi lựa chọn dụng cụ hoặc linh kiện cacbua vonfram, hãy cân nhắc:

Yêu cầu ứng dụng – Loại vật liệu được gia công, điều kiện cắt, bề mặt hoàn thiện mong muốn

Hình dạng dụng cụ – Hình dạng và kích thước ảnh hưởng đến hiệu suất và tuổi thọ

Lớp phủ và lớp phủ – Phù hợp với độ cứng Và độ dẻo dai cần thiết

Chất lượng nhà cung cấp – Nhà cung cấp đáng tin cậy đảm bảo hiệu suất nhất quán

Phần kết luận

Cacbua vonfram đóng vai trò quan trọng trong sản xuất hiện đại. Sự kết hợp độc đáo giữa độ cứng, độ dẻo dai và khả năng chống mài mòn khiến nó trở thành vật liệu lý tưởng cho các công cụ hiệu suất cao và các chi tiết chịu mài mòn.

Đối với những người ra quyết định, việc hiểu rõ khả năng và ứng dụng của cacbua vonfram có thể đưa đến những lựa chọn mua hàng tốt hơn, giảm chi phí sản xuất và cải thiện chất lượng sản phẩm.

Bằng cách lựa chọn giải pháp cacbua vonfram phù hợp, các công ty có thể tăng hiệu quả, kéo dài tuổi thọ dụng cụ và duy trì khả năng cạnh tranh trong môi trường sản xuất khắt khe hiện nay.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.