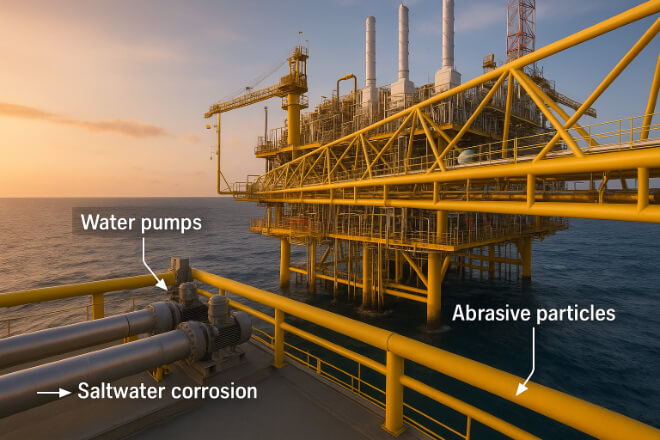

Marine and offshore industries face some of the harshest working conditions on earth.

Saltwater, pressure, vibration, and constant exposure to abrasive particles create extreme stress on machinery components.

Pumps, compressors, and rotating equipment must operate continuously with little room for error.

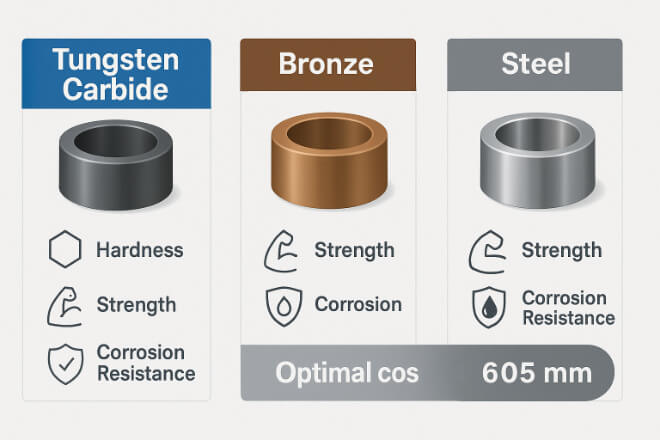

In such environments, ống lót cacbua vonfram play a vital role. They provide dimensional stability, khả năng chống mài mòn, and corrosion protection where traditional metals like bronze or stainless steel often fail.

This article explains why tungsten carbide bushings are essential for marine and offshore use, how they handle corrosion and wear, and the design factors that make them a long-term investment in reliability.

Environmental Challenges in Marine and Offshore Systems

Saltwater is a powerful enemy of metals. It contains chlorides and dissolved oxygen, which accelerate corrosion.

Offshore machinery also faces abrasive sand, pressure changes, and limited access for maintenance.

Key operating conditions include:

Constant exposure to seawater and brine.

High mechanical load from pumps and rotating shafts.

Abrasion from particles in ballast or cooling water.

Temperature and pressure variation.

Limited on-site maintenance or replacement access.

Under these conditions, conventional bronze or steel bushings wear quickly — leading to shaft misalignment, vibration, and seal failure.

Ống lót cacbua vonfram offer a reliable solution to these problems.

Why Tungsten Carbide Performs Better

Tungsten carbide (WC) is made from tungsten and carbon combined with a metallic binder such as nickel or cobalt.

It offers the độ cứng of a ceramic and the strength of a metal, making it ideal for harsh marine conditions.

Key Advantages:

High hardness (88–92 HRA) for abrasion resistance.

Xuất sắc khả năng chống ăn mòn (especially with nickel binder).

Low thermal expansion for dimensional stability.

High compressive strength (>4000 MPa) for heavy-duty loads.

Long wear life in continuous saltwater exposure.

These properties ensure reliable operation for years, even in offshore pumps or subsea compressors.

Corrosion Behavior in Saltwater

| Vật liệu | Khả năng chống ăn mòn | Service Life (Approx.) |

|---|---|---|

| Bronze | Poor – prone to dezincification | 3–6 months |

| Stainless Steel | Moderate – affected by pitting and crevice corrosion | 1 year |

| Nickel-Bonded Tungsten Carbide | Excellent – inert to seawater and brine | 3–5 years or more |

Nickel-bonded tungsten carbide forms a stable passive layer that protects it from oxidation and chloride attack.

Even in high-salinity seawater or marine diesel systems, carbide bushings maintain their surface finish without pitting or discoloration.

Wear and Erosion Protection

Offshore equipment often pumps water with entrained sand or fine solids that act like abrasives.

Over time, these particles can wear out steel components, especially at shaft interfaces.

Tungsten carbide’s micrograin structure resists cutting, grinding, and surface erosion.

Its độ cứng prevents deformation, maintaining tight shaft clearances and smooth operation.

In cooling water or fire pump systems, carbide bushings reduce wear-related vibration and extend mean time between overhauls (MTBO).

Applications in Marine and Offshore Equipment

| Equipment | Environment | Function of Bushing |

|---|---|---|

| Seawater Lift Pump | High chloride, moderate solids | Shaft support and alignment |

| Ballast Water Pump | Continuous seawater flow | Bearing and corrosion shield |

| Firewater Pump | High velocity, intermittent operation | Wear protection under cavitation |

| Subsea Motor or Compressor | Pressurized and corrosive conditions | Sealing and load-bearing support |

These applications highlight the wide use of tungsten carbide bushings in critical marine systems — both topside and subsea — where reliability is essential.

Binder Selection for Offshore Use

| Loại chất kết dính | Performance | Recommended Use |

|---|---|---|

| Coban (Co) | High toughness but moderate corrosion resistance | Freshwater or non-corrosive offshore systems |

| Niken (Ni) | Excellent corrosion resistance in saltwater | Seawater, ballast, and subsea environments |

For most offshore installations, nickel-bonded carbide is the top choice because of its ability to resist chloride attack and maintain mechanical strength over long service intervals.

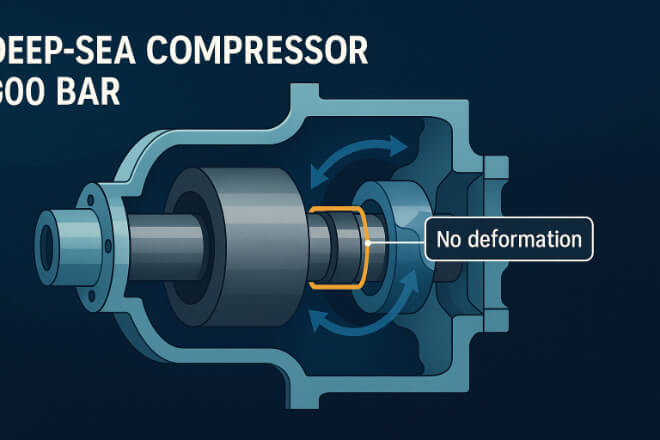

Thermal and Pressure Stability

Marine equipment often experiences large temperature and pressure variations.

Tungsten carbide’s low thermal expansion ensures stable performance in both cold seawater and high-pressure subsea systems.

Even under pressures exceeding 300 bar, carbide bushings maintain dimensional accuracy and alignment — preventing vibration and premature seal wear.

This makes them suitable for subsea compressors, pumps, and deep-sea drilling systems.

Real-World Case Study

| System | Old Bushing Material | Service Life Before | Service Life After (WC) | Maintenance Reduction |

|---|---|---|---|---|

| Offshore Firewater Pump | Bronze | 6 months | 4 years | 85% |

| Ballast Pump | Stainless Steel | 1 year | 3.5 years | 70% |

After switching to ống lót cacbua vonfram, both systems showed a significant increase in uptime and reduction in maintenance costs — confirming their value in long-term offshore operations.

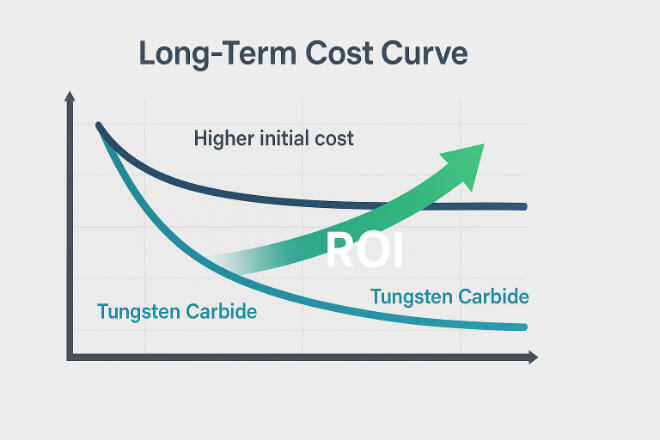

Cost and Life-Cycle Benefits

While ống lót cacbua vonfram are more expensive initially, their durability greatly reduces the total cost of ownership.

Each avoided shutdown or replacement saves labor, logistics, and production downtime costs — which are extremely high offshore.

In many cases, operators recover the higher upfront cost within the first maintenance cycle, as equipment reliability increases and parts last several times longer.

Phần kết luận

For marine and offshore environments, tungsten carbide bushings are the clear choice for performance and reliability.

Their combination of hardness, corrosion resistance, and stability ensures continuous operation under seawater, pressure, and abrasive exposure.

By choosing the right binder and design, decision-makers can achieve long service life, reduced maintenance, and lower operating costs — essential factors for offshore efficiency and safety.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.