Linh kiện mài mòn cacbua vonfram được sử dụng trong các ngành công nghiệp như khai thác mỏ, dầu khí, sản xuất và gia công kim loại vì tính chất cao của chúng độ cứng, khả năng chống mài mònvà tuổi thọ cao.

Mặc dù chúng bền hơn thép rất nhiều nhưng cuối cùng chúng vẫn bị mòn hoặc hỏng.

Đối với những người ra quyết định, việc biết khi nào cần thay thế các thành phần này là chìa khóa để tránh thời gian ngừng hoạt động tốn kém, bảo vệ các bộ phận máy khác và duy trì hiệu quả sản xuất.

Trong hướng dẫn này, chúng tôi sẽ giải thích các dấu hiệu cho thấy cần thay thế, cách thực hiện đúng và cách kéo dài tuổi thọ của các linh kiện mới.

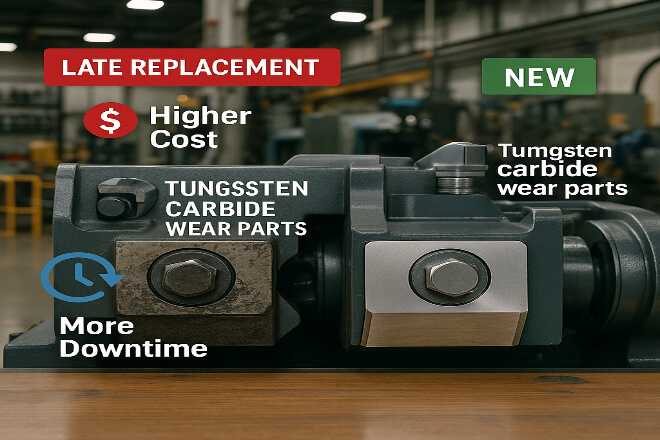

Tại sao thời điểm thay thế lại quan trọng

Việc thay thế các bộ phận hao mòn cacbua vonfram quá muộn có thể dẫn đến:

Thời gian ngừng hoạt động không theo kế hoạch

Chi phí sửa chữa cao hơn

Thiệt hại cho các bộ phận khác

Chất lượng sản phẩm thấp hơn

Tuy nhiên, việc thay thế quá sớm có thể gây lãng phí tài nguyên. Cần cân bằng giữa việc theo dõi các bộ phận hao mòn thường xuyên và thay thế chúng vào thời điểm tối ưu.

Dấu hiệu phổ biến cho thấy một thành phần cần được thay thế

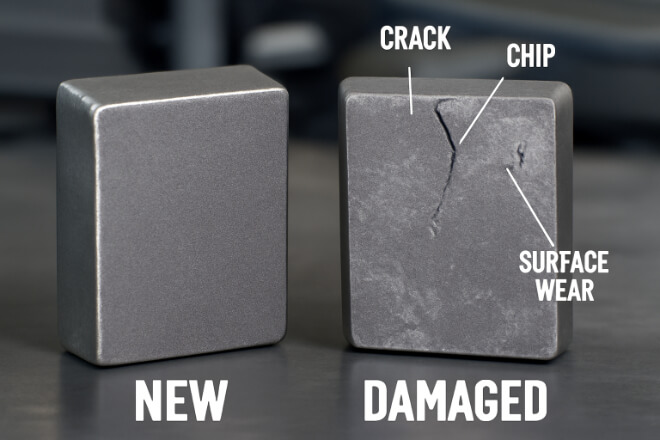

Mặc quá mức

Nếu bề mặt làm việc bị mất độ dày hoặc hình dạng vật liệu đáng kể, nó có thể không còn hoạt động hiệu quả. Điều này có thể dẫn đến sai lệch, quá nhiệt hoặc giảm hiệu suất cắt.

Nứt hoặc sứt mẻ

Các vết nứt nhỏ trên cacbua vonfram có thể nhanh chóng phát triển dưới áp lực, dẫn đến hỏng hóc đột ngột. Bất kỳ vết sứt mẻ nào nhìn thấy được đều là dấu hiệu rõ ràng cho thấy cần phải thay thế.

Giảm hiệu suất

Nếu máy móc của bạn cần nhiều năng lượng hơn, tạo ra sản phẩm chất lượng thấp hơn hoặc hoạt động chậm lại thì nguyên nhân có thể là do các bộ phận bị mòn.

Tăng độ rung hoặc tiếng ồn

Các bộ phận bị mòn thường gây mất cân bằng, dẫn đến rung động hoặc tiếng ồn bất thường trong quá trình vận hành.

Các yếu tố ảnh hưởng đến khoảng thời gian thay thế

Các điều kiện làm việc khác nhau sẽ thay đổi tần suất cần thay thế các bộ phận hao mòn.

| Nhân tố | Tác động đến tuổi thọ sử dụng |

|---|---|

| Vật liệu được xử lý | Vật liệu mài mòn như cát hoặc thủy tinh làm giảm tuổi thọ |

| Nhiệt độ hoạt động | Nhiệt độ cao có thể làm yếu cacbua và gây ra các vết nứt |

| Tải trọng và áp suất | Tải trọng cao hơn làm tăng tốc độ mệt mỏi |

| Chất lượng bôi trơn | Bôi trơn kém làm tăng ma sát và mài mòn |

| Sốc và va chạm | Những va chạm thường xuyên có thể làm sứt mẻ các cạnh cacbua |

Cách kiểm tra các bộ phận hao mòn cacbua vonfram

Kiểm tra thường xuyên là chìa khóa để thay thế kịp thời.

Bước 1 – Kiểm tra trực quan

Kiểm tra các vết nứt, vết mẻ, sự đổi màu hoặc độ mòn không đều.

Bước 2 – Đo kích thước

Sử dụng thước cặp hoặc micrômet để đo độ dày, chiều dài hoặc đường kính và so sánh với thông số kỹ thuật ban đầu.

Bước 3 – Xem xét dữ liệu hiệu suất

Theo dõi hiệu suất máy, mức tiêu thụ điện năng và chất lượng đầu ra.

Bước 4 – Hồ sơ bảo trì

Ghi lại tốc độ hao mòn theo thời gian để dự đoán lịch trình thay thế.

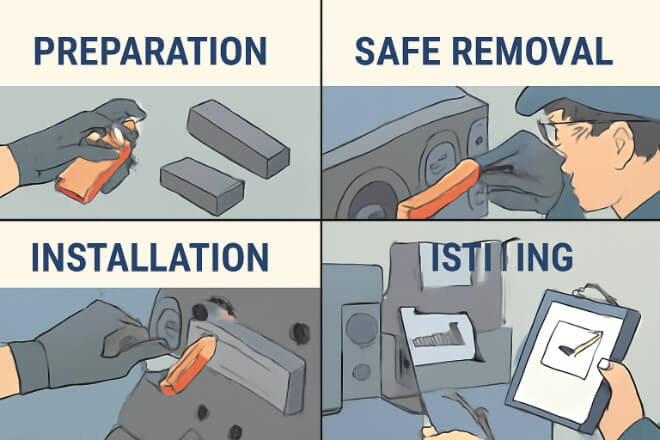

Quy trình thay thế: từng bước

1). Chuẩn bị thành phần mới

Đảm bảo rằng nó có đúng loại và đúng kích cỡ.

Kiểm tra thông số kỹ thuật của nhà sản xuất.

Kiểm tra xem có bất kỳ lỗi nào trước khi lắp đặt.

2). Tháo bỏ linh kiện cũ một cách an toàn

Tắt máy và khóa máy.

Sử dụng đúng công cụ để tránh làm hỏng các bộ phận xung quanh.

Vứt bỏ các bộ phận bị mòn theo hướng dẫn tái chế.

3). Cài đặt thành phần mới

Thực hiện theo hướng dẫn về mô-men xoắn và căn chỉnh của nhà sản xuất.

Sử dụng chất bôi trơn thích hợp nếu cần thiết.

Tránh dùng lực quá mạnh khi lắp.

4). Kiểm tra sau khi lắp đặt

Chạy thử máy ở tốc độ thấp.

Theo dõi tiếng ồn, độ rung hoặc rò rỉ.

Kiểm tra lại các chốt sau vài giờ hoạt động đầu tiên.

Tái chế cacbua vonfram bị mòn

Cacbua vonfram có thể được tái chế để thu hồi vonfram và coban có giá trị. Việc hợp tác với một công ty tái chế đáng tin cậy có thể:

Giảm chi phí

Giảm tác động đến môi trường

Đảm bảo tuân thủ các quy định về chất thải

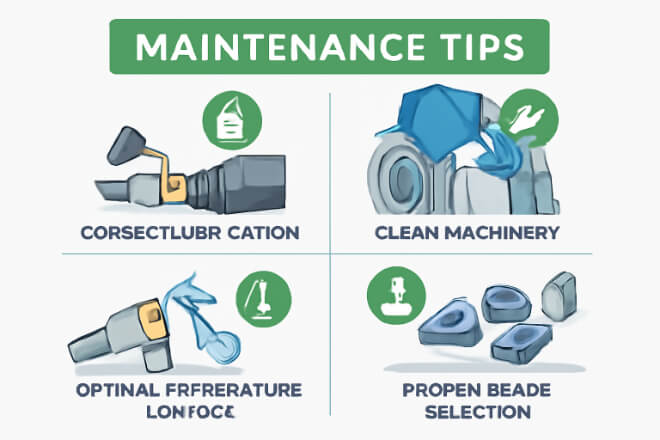

Kéo dài tuổi thọ của các bộ phận hao mòn

Linh kiện của bạn dùng càng lâu thì bạn càng ít phải thay thế.

Chọn đúng loại – Các loại cacbua vonfram khác nhau được thiết kế cho các điều kiện cụ thể.

Cải thiện khả năng bôi trơn – Sử dụng chất bôi trơn phù hợp với môi trường của bạn.

Kiểm soát điều kiện vận hành – Tránh những tác động không cần thiết và quá nhiệt.

Bảo trì thường xuyên – Thường xuyên vệ sinh, kiểm tra và điều chỉnh máy móc.

Danh sách kiểm tra bảo trì và thay thế

| Kiểm tra mục | Tính thường xuyên | Hoạt động |

|---|---|---|

| Kiểm tra trực quan | Hàng tuần | Kiểm tra các vết nứt, vết mẻ hoặc sự đổi màu |

| Đo lường kích thước | Hàng tháng | So sánh với thông số kỹ thuật ban đầu |

| Bôi trơn | Hàng ngày/Khi cần thiết | Đảm bảo đúng chủng loại và vệ sinh |

| Đánh giá hiệu suất | Hàng tháng | Theo dõi chất lượng đầu ra và mức sử dụng năng lượng |

| Thay thế | Theo yêu cầu | Thực hiện theo khuyến nghị của nhà sản xuất |

Làm việc với các nhà cung cấp đáng tin cậy

Nhà cung cấp phù hợp có thể giúp:

Phân tích các kiểu hao mòn

Đề xuất các loại cacbua tốt hơn

Cung cấp sản phẩm thay thế được chế tạo chính xác

Cung cấp dịch vụ giao hàng nhanh hơn cho các trường hợp thay thế khẩn cấp

Phần kết luận

Đối với những người ra quyết định trong các ngành công nghiệp phụ thuộc vào các bộ phận chịu mài mòn bằng cacbua vonfram, việc biết khi nào và cách thay thế các bộ phận là rất quan trọng.

Việc trì hoãn thay thế có nguy cơ làm hỏng thiết bị và mất sản lượng, trong khi việc thay thế quá sớm sẽ lãng phí tài nguyên.

Bằng cách theo dõi các chỉ số hao mòn, thực hiện quy trình thay thế phù hợp và hợp tác với các nhà cung cấp đáng tin cậy, các công ty có thể giảm thời gian ngừng hoạt động, cắt giảm chi phí bảo trì và kéo dài tuổi thọ chung của thiết bị.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.