Every machine depends on small parts to work well. One of the most trusted small parts in modern industries is the tungsten carbide ball.

These balls are used in valves, bearings, flowmeters, drilling tools, and many other systems.

Decision-makers often ask: Why should we choose tungsten carbide balls instead of steel or ceramic balls?

The answer is simple—they are stronger, last longer, and bring better value over time.

This article explains the benefits and uses of tungsten carbide balls. We will look at how they improve performance, reduce costs, and support industries that need both precision and strength.

What Makes Tungsten Carbide Balls Different?

Tungsten carbide is a compound made of tungsten and carbon.

It is one of the hardest materials available for industrial use. A binder, usually cobalt or nickel, is added to improve toughness.

Key features include:

Rất cao độ cứng (gần kim cương)

Dài wear resistance, even in rough conditions

Ability to keep shape under high pressure

Strong resistance to corrosion

Compared to standard steel balls, tungsten carbide balls provide far greater durability. This makes them a top choice in systems where reliability is critical.

Benefits of Tungsten Carbide Balls

1). Cực đoan Độ cứng

Tungsten carbide balls can resist heavy loads and high impact without breaking.

This makes them perfect for industries like hàng không vũ trụ, dầu khí, and heavy machinery.

2). Longer Service Life

They last many times longer than regular steel balls. Less replacement means less downtime and lower maintenance costs.

3). Wear and Khả năng chống ăn mòn

Even in contact with abrasive fluids, chemicals, or extreme heat, tungsten carbide balls maintain their strength and surface finish.

4). Better Precision

For measuring devices and flow control systems, their stable shape ensures accurate results over time.

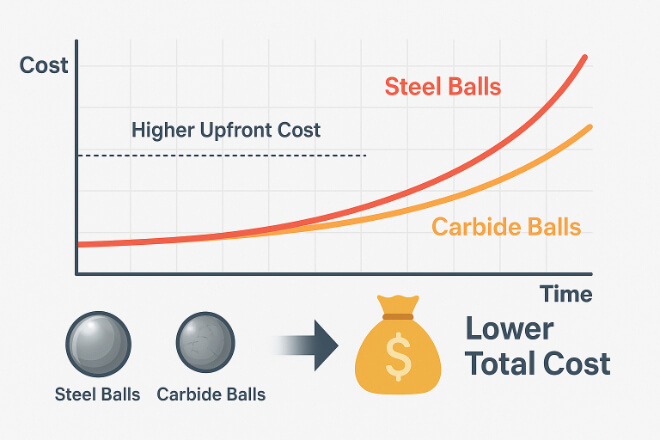

5). Cost Efficiency

Although the purchase cost is higher, the overall savings are much greater because of their long life and reduced failure rate.

Main Uses of Tungsten Carbide Balls

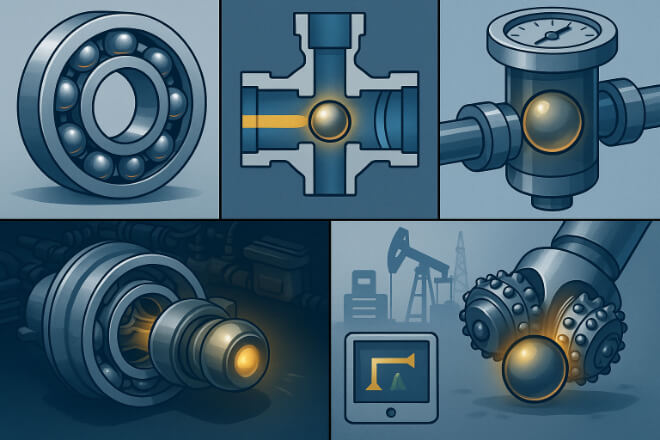

Bearings

Carbide balls inside bearings help machines run smoothly under high load. They are used in turbines, engines, and precision machinery.

In pipeline and pump systems, tungsten carbide balls work as sealing elements. They prevent leaks, even under extreme pressure or in corrosive liquids.

Flowmeters

Small precision balls inside flowmeters allow accurate control of gas and liquid flow. They keep readings stable for years.

From turbochargers to control parts, carbide balls ensure engines and systems can handle high heat and speed.

Dầu khí Drilling

Drilling tools and mud motors use tungsten carbide balls to withstand abrasion and heavy impact underground.

Industrial Tools

Carbide balls are also used in grinding, milling, and precision instruments where strength and accuracy are required.

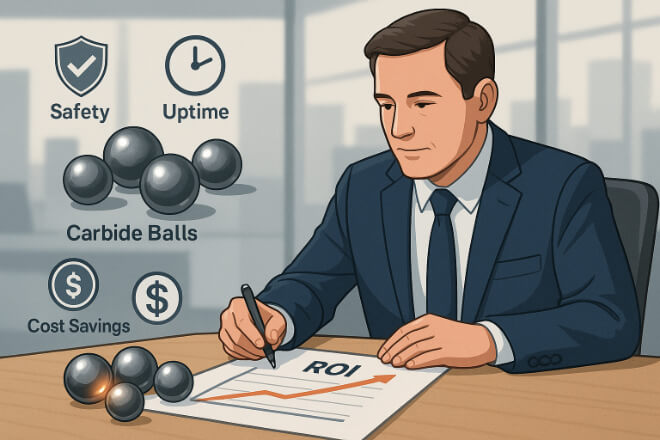

Why Decision-Makers Should Care

For company leaders and purchasing managers, the choice of materials directly affects business results.

Choosing tungsten carbide balls brings benefits beyond technical performance.

Fewer Breakdowns → less production loss

Higher Safety → stronger seals in valves and pumps

ROI tốt hơn → longer life compared to steel balls

Global Standards → widely accepted in aerospace, oil & gas, and chemical industries

This makes tungsten carbide balls not only an engineering choice but also a smart business decision.

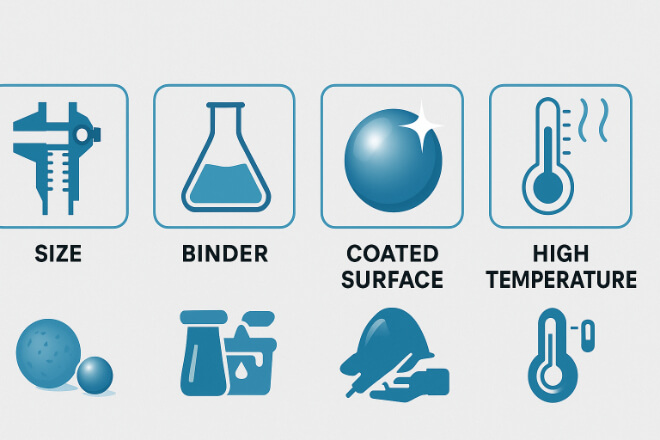

How to Select the Right Tungsten Carbide Balls

Not all applications require the same type of ball. Decision-makers should consider:

Size and Diameter – Must match system requirements. Small balls are better for precision, larger ones for heavy load.

Binder Type – Cobalt binder offers toughness; nickel binder offers better corrosion resistance.

Precision Grade – High-grade balls are used in flowmeters and measuring tools.

Coating – Some balls are coated for extra wear protection.

Environment – Consider temperature, pressure, and the type of liquid or gas.

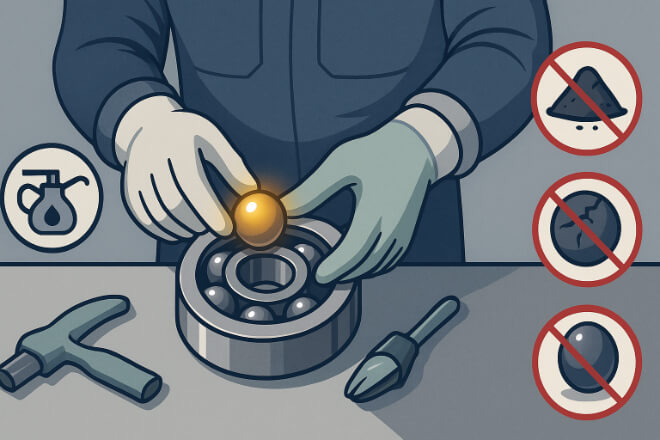

Best Practices in Use

To gain the most from tungsten carbide balls:

Install them with proper tools and alignment.

Use correct lubrication to reduce friction.

Inspect regularly for wear or cracks.

Keep systems clean to avoid dirt or sand damage.

Follow manufacturer guidelines on load and temperature limits.

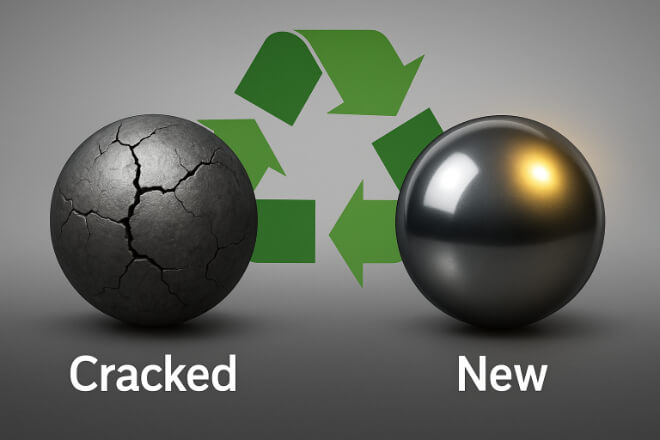

Maintenance and Replacement

Even the strongest carbide balls wear out with time. A clear maintenance plan helps prevent sudden failure.

Inspection Cycle: Critical systems should be checked every few weeks.

Warning Signs: Noise in bearings, leaks in valves, or reduced measurement accuracy.

Replacement Policy: Always replace with the same size and grade to ensure system performance.

Recycling: Tungsten carbide can be recycled, lowering replacement cost.

Cost and Value for Companies

While tungsten carbide balls cost more upfront than steel balls, their long life brings real savings.

5–10 times longer lifespan

Less downtime and repair

Reduced risk of accidents

Stronger long-term return on investment

For industries where equipment failure is very costly, these advantages make a strong financial case.

Ví dụ trường hợp

1). Oil & Gas Industry

Switching from steel to tungsten carbide balls in check valves reduced leakage and downtime, saving thousands of hours in drilling operations.

2). Automotive Industry

Turbochargers with carbide balls lasted longer and performed better under high heat, improving fuel efficiency.

3). Chemical Industry

Carbide balls in chemical pumps prevented corrosion and leakage, improving both safety and efficiency.

How to Source Tungsten Carbide Balls

When buying carbide balls, companies should:

Choose trusted suppliers with ISO certifications

Check stock availability for faster delivery

Ask for customization if special sizes or coatings are needed

Confirm technical support for testing and consultation

For supplier lists and resources, you can visit Retopz.com.

Phần kết luận

Tungsten carbide balls are small components with a big impact. Their strength, wear resistance, and precision make them essential for industries that demand reliability.

For decision-makers, choosing tungsten carbide balls means fewer failures, reduced downtime, safer operations, and better cost efficiency. That is why they remain the preferred choice across industries worldwide.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.