Các dầu khí industry operates in one of the toughest environments on Earth.

Equipment used in drilling, pumping, and refining faces high pressure, abrasive fluids, extreme temperatures, and corrosive chemicals.

To keep systems running safely and efficiently, every component must deliver exceptional reliability.

Among these components, ống lót cacbua vonfram play a vital role. They support rotating shafts, minimize friction, and protect critical equipment such as mud pumps, compressors, turbines, and subsea systems.

This article explains why tungsten carbide bushings are essential for oil and gas applications, how they improve reliability, and what makes them superior to conventional materials.

The Harsh Operating Conditions in Oil and Gas

Dầu khí operations expose machinery to conditions that quickly wear out ordinary materials.

Typical challenges include:

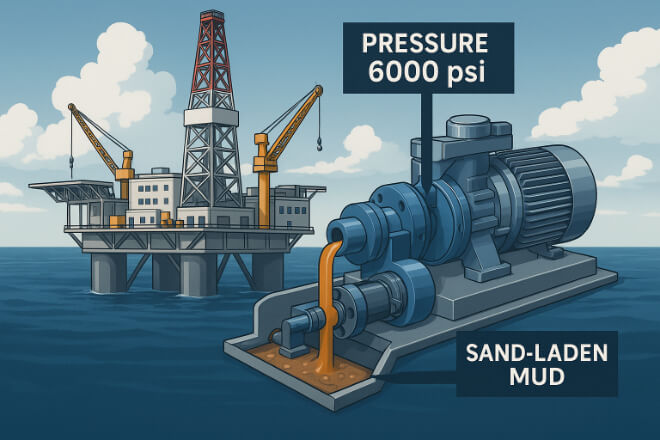

High pressure: Often exceeding 6000 psi in deep-well or high-lift pumps.

Abrasive media: Sand, drilling mud, or particulates in crude oil.

Corrosive fluids: Containing sulfur compounds, brine, or CO₂.

Temperature extremes: From cryogenic LNG processing to superheated steam injection.

Continuous operation: Many systems run 24/7 with minimal downtime.

In these conditions, traditional bronze or stainless-steel bushings wear rapidly, leading to vibration, leakage, or even catastrophic equipment failure. Tungsten carbide bushings, however, are built to survive.

Key Material Advantages of Tungsten Carbide

Tungsten carbide (WC) is a composite material combining hard tungsten particles with a metallic binder (usually cobalt or nickel).

It provides the strength of metal with the độ cứng of ceramic.

| Vật liệu | Khả năng chống mài mòn | Khả năng chống ăn mòn | Typical Lifetime |

|---|---|---|---|

| Bronze | Thấp | Nghèo | 3–6 months |

| Stainless Steel | Trung bình | Tốt | 1 year |

| Cacbua Vonfram | Xuất sắc | Excellent (Ni binder) | 3–5 years |

Tungsten carbide’s hardness (88–92 HRA) and compressive strength (>4000 MPa) make it one of the most durable materials for rotating equipment in oil and gas operations.

Applications in Drilling and Mud Pumps

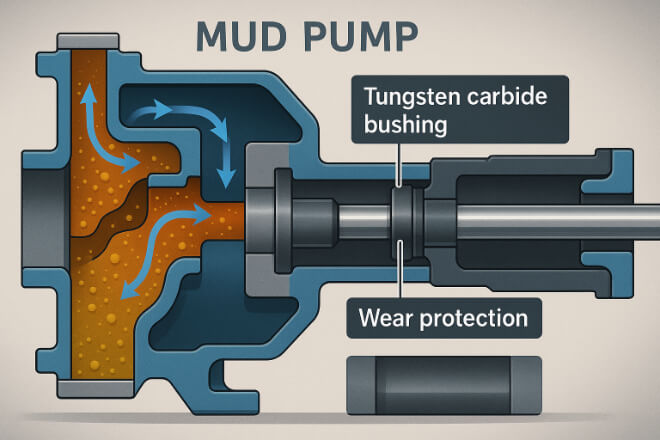

Drilling rigs use heavy-duty pumps to move drilling mud, a mixture that cools the bit and removes cuttings.

This mud contains abrasive sand, rock, and chemicals that quickly destroy conventional bushings.

Ống lót cacbua vonfram được sử dụng trong:

Mud pump liners and wear sleeves

Plunger pump housings

Agitator shaft supports

Bởi vì của họ khả năng chống mài mòn and low friction, they maintain tight clearances, reducing vibration and improving pump efficiency.

In deep drilling applications, carbide bushings can operate thousands of hours without visible wear — even in high-sand content mud.

Applications in Downhole Tools and Subsea Systems

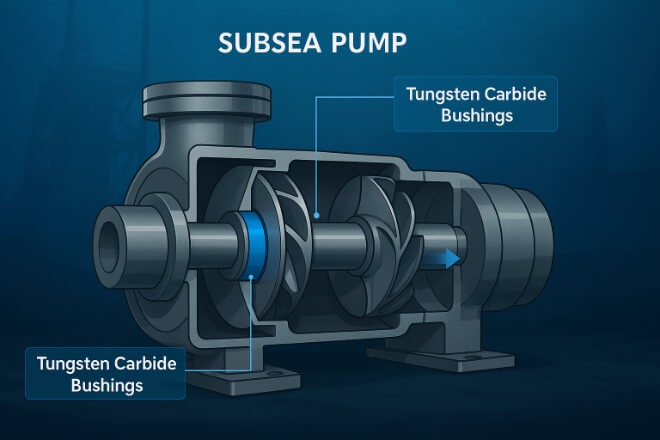

Downhole tools and subsea pumps operate in extreme conditions — under immense pressure, in saltwater, and often without maintenance for years.

Tungsten carbide bushings are commonly used in:

Electric submersible pumps (ESP)

Subsea motor shafts and bearings

Control valves and flow restrictors

Nickel-bonded carbide types are preferred in subsea environments because of their excellent khả năng chống ăn mòn against seawater and chemical injection fluids.

These bushings ensure reliable operation in places where replacement or repair is costly or nearly impossible.

Applications in Compressors and Turbines

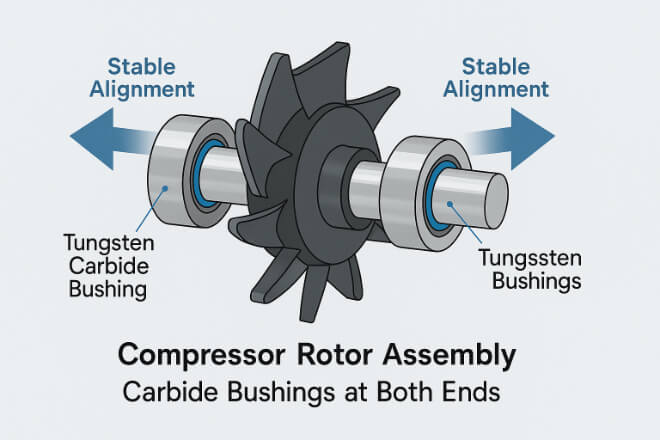

Gas compressors and turbines in refineries or LNG plants run continuously, handling high-speed rotation and heat.

In these machines, even small alignment errors can cause vibration or bearing failure.

Tungsten carbide bushings are used in:

Compressor balance sleeves

Turbine guide bushings

Gearbox bearing housings

Their low thermal expansion ensures accurate shaft alignment, even under temperature fluctuations.

Additionally, their polished surfaces reduce energy loss through friction, improving overall efficiency.

Binder Type Selection for Oil & Gas

| Loại chất kết dính | Khả năng chống ăn mòn | Độ dẻo dai | Recommended Environment |

|---|---|---|---|

| Coban (Co) | Vừa phải | Cao | High-load, non-acidic drilling systems |

| Niken (Ni) | Xuất sắc | Tốt | Corrosive or subsea chemical exposure |

The correct binder choice ensures optimal durability based on chemical exposure and mechanical load.

Resistance to Corrosion and Erosion

Oil and gas media often contain hydrogen sulfide, brine, and acidic compounds that cause pitting and chemical attack on metal parts.

Nickel-bonded tungsten carbide offers superior protection due to its passive surface layer that prevents oxidation.

Erosion from sand and particulates is also a major problem. Carbide bushings resist micro-cutting by maintaining their hardness even at high temperatures, unlike stainless steel, which softens over time.

The result is a dramatic reduction in maintenance frequency and consistent performance under extreme stress.

Reliability and Downtime Reduction

In oil and gas operations, downtime is extremely costly — sometimes thousands of dollars per minute.

A single component failure can stop production for hours or days.

Tungsten carbide bushings reduce downtime by:

Preventing shaft misalignment and seal wear

Maintaining clearances for stable operation

Extending mean time between maintenance (MTBM)

Operating safely in corrosive or abrasive fluids

This high reliability justifies the initial investment and offers a much lower total life-cycle cost compared to cheaper alternatives.

Real-World Example

| Vật liệu | Operating Condition | Service Life | Maintenance Frequency |

|---|---|---|---|

| Bronze | Moderate sand, seawater | 6 months | Cao |

| Stainless Steel | Saltwater, mild corrosion | 1 year | Trung bình |

| Nickel-Bonded Tungsten Carbide | Abrasive, corrosive subsea | 3–5 years | Thấp |

The data clearly shows that tungsten carbide bushings outperform other materials, particularly in offshore and subsea applications where repair costs are high.

Phần kết luận

In the oil and gas industry, equipment reliability determines profitability. Tungsten carbide bushings are essential because they combine mechanical strength, corrosion resistance, and long service life.

Whether used in pumps, compressors, turbines, or subsea systems, they help reduce downtime, improve safety, and extend operational life.

For decision-makers, investing in tungsten carbide bushings is not just a material choice — it’s a strategic decision for long-term equipment performance and cost control.

Nếu bạn muốn biết thêm chi tiết về bất kỳ công ty nào, vui lòng liên hệ với chúng tôi.