Tungsten Carbide Wear Parts Manufacturer

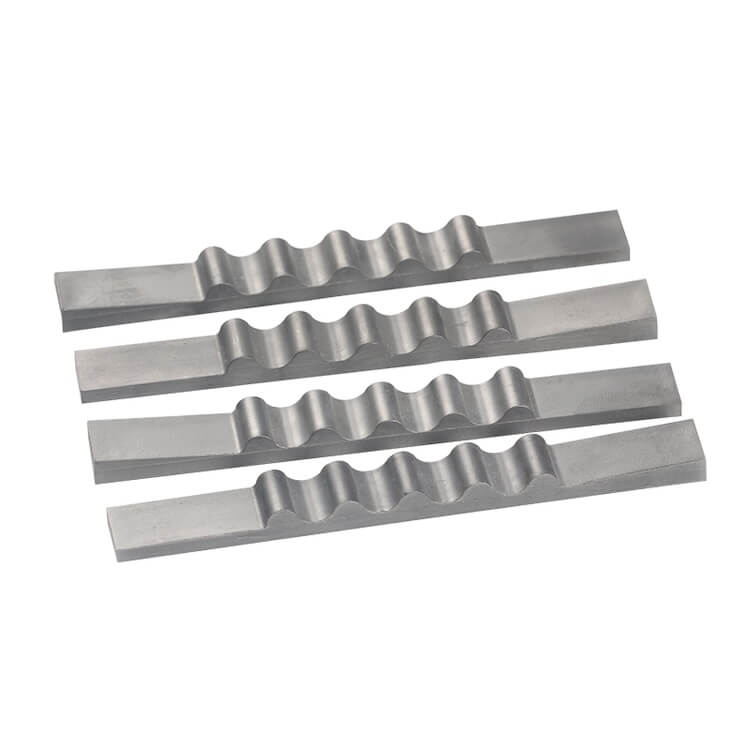

At Retop, we manufacture precision tungsten carbide wear parts engineered for superior durability in mining, construction, fluid handling, and heavy-duty applications. Custom shapes, grades, and tolerances available.

Tungsten Carbide Wear Parts Product Categories

Explore our full range of tungsten carbide wear parts, engineered for superior performance in abrasion, impact, and high-pressure industrial applications across multiple demanding sectors.

Quick and easy: Enter your specifications and get a quote in one business day

Carbide Grade Chart

Choosing the right carbide grade is essential for optimal performance and longevity. Below is a detailed description of commonly used Retop tungsten carbide grades, their chemical composition, and mechanical properties.

| Retop Grade | ISO Grade | Chemical Composition | Physical Mechanical Properties | ||||

| WC | Co | Density | Bend Strength | Hardness | |||

| % | % | G/Cm3 | N/mm2 | HRA | |||

| YG3 | K01 | 96.5–97 | 3 | 14.9–15.3 | ≥1180 | ≥92.5 | |

| YG6X | K10 | 93.5 | 6 | 14.8–15.1 | ≥1420 | ≥92 | |

| YG6 | K20 | 94 | 6 | 14.7–15.1 | ≥1600 | ≥91 | |

| YG8 | K20–K30 | 92 | 8 | 14.5–14.9 | ≥1600 | ≥90 | |

| YG10 | K40 | 90 | 10 | 14.3–14.7 | ≥1900 | ≥89 | |

| YG10X | K40 | 89 | 10 | 14.3–14.7 | ≥2200 | ≥90 | |

| YG15 | K30 | 85 | 15 | 13.9–14.2 | ≥2100 | ≥87 | |

| YG20 | K30 | 80 | 20 | 13.4–13.7 | ≥2500 | ≥85.5 | |

How to Select the Right Carbide Grade?

Choosing the correct tungsten carbide grade is essential for achieving optimal wear resistance, toughness, and performance in your specific application. The right grade ensures longer service life, lower maintenance, and improved efficiency.

1. Understand Your Application Requirements

| Condition | What You Need |

|---|---|

| High Abrasion | Fine grain, high hardness |

| Impact / Shock | More cobalt, higher toughness |

| Corrosive Environment | Nickel binder or anti-corrosion grade |

| Precision Fit | Submicron carbide, tight tolerance |

2. Compare Carbide Grades

| Grade | Co% | Hardness (HRA) | Feature | Best Use |

|---|---|---|---|---|

| YG6X | 6% | ~92.0 | High hardness | Cutting, valves |

| YG8 | 8% | ~90.0 | Balanced toughness | Seal sleeves |

| YG10X | 10% | ~91 | Impact resistant | Plungers |

| YG11C | 11% | ~86 | Maximum toughness | Mining |

3. Recommended Grades by Industry

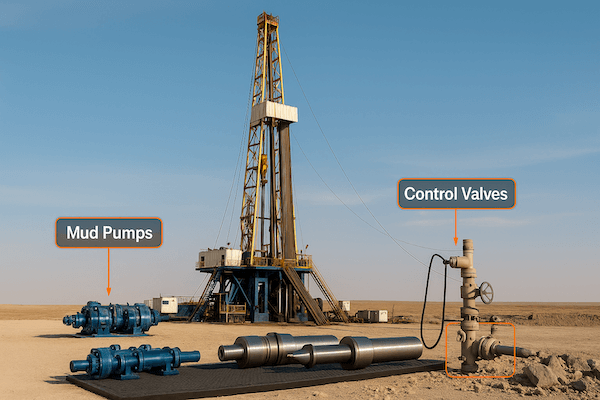

Oil & Gas

YG6, YG8, YN9, YN12Mining

YG11C, YG6, YG10Pump & Seals

YG6, YG8, YG10XCold Forming

YG8, YG10, YG15Quick and easy: Enter your specifications and get a quote in one business day

Application Scenarios for Tungsten Carbide Wear Parts

Explore how tungsten carbide wear parts are applied in mining, oil & gas, fluid sealing, metal forming, and high-wear industrial environments to improve durability and reduce equipment downtime.

Oil & Gas Industry

Tungsten carbide wear parts are widely used in downhole tools, drilling stabilizers, valve trims, and mud nozzles for their extreme wear and corrosion resistance in high-pressure environments.

Mining & Construction

Used in rock drilling bits, tunneling machines, and excavation equipment, carbide parts offer high impact toughness and abrasion resistance to extend equipment service life in harsh terrain.

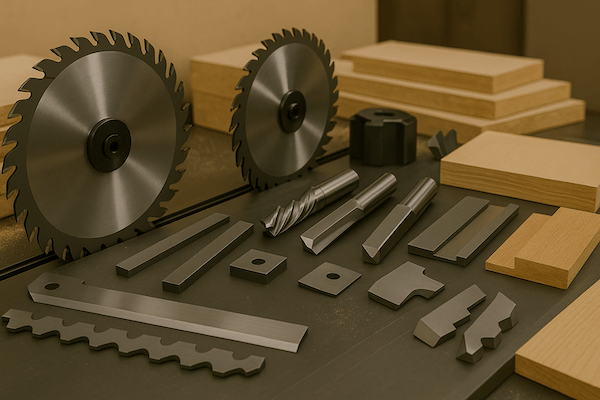

Woodworking Industry

Carbide blades, cutters, and planer knives are essential for high-speed woodworking machines, offering sharpness retention, clean finishes, and resistance to resin buildup during long production cycles.

Metal Forming & Stamping Industry

Cold heading dies, drawing dies, and carbide punches ensure dimensional accuracy and long life in high-volume forming operations for automotive, aerospace, and electronics components.

Why Choose Retop for Tungsten Carbide Wear Parts Supplier?

Discover why Retop is trusted globally for tungsten carbide wear parts—offering precision manufacturing, customized material grades, strict quality control, and technical support tailored to your industrial applications.

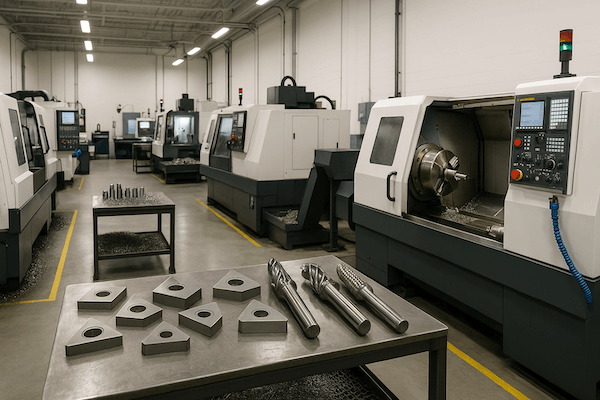

Production Process of Tungsten Carbide Wear Parts

Explore the key steps in producing tungsten carbide wear parts—from powder mixing and sintering to precision grinding and inspection—ensuring durability, accuracy, and performance in demanding applications.

Top 10 FAQs for Tungsten Carbide Wear Parts

Find quick answers to the most common questions about tungsten carbide wear parts—covering applications, materials, custom manufacturing, lead time, and technical support for your industrial needs.

1. What are tungsten carbide wear parts used for?

Tungsten carbide wear parts are used in applications involving high abrasion, impact, or corrosion—such as mining tools, pump sleeves, valve components, and metal-forming dies.

2. What industries do your wear parts serve?

We supply carbide wear parts to the mining, oil & gas, fluid handling, construction, automotive, and metal forming industries.

3. What materials and grades do you offer?

We offer a full range of WC-Co and WC-Ni grades, including fine grain, submicron, and coarse grain carbide. Common grades include YG6X, YG8, YG10X, and YG20.

4. Can you manufacture parts based on customer drawings?

Yes. We specialize in custom wear parts based on your 2D/3D drawings or physical samples, with tolerances up to ±0.01 mm.

5. What is the typical lead time for production?

Standard lead time is 15–25 days depending on the complexity and quantity. Urgent orders can be expedited upon request.

6. Do you provide surface treatment or finishing?

Yes, we offer precision grinding, polishing, and coating options like TiN or TiAlN upon request.

7. How do I select the right carbide grade for my application?

Our engineers can recommend the best grade based on your operating conditions (wear, impact, corrosion). You can also refer to our Carbide Grade Selection Guide on the page.

8. Can I request material certification or inspection reports?

Yes. We provide full quality documentation including density, hardness, and metallographic reports with each batch.

9. Do you offer samples for testing before bulk orders?

Yes. Samples are available for most standard parts or small-batch custom prototypes.

10. What packaging and shipping methods do you use?

All products are securely packed in anti-impact foam and export-grade cartons. We support express, air freight, and sea freight shipping options globally.

Quick and easy: Enter your specifications and get a quote in one business day