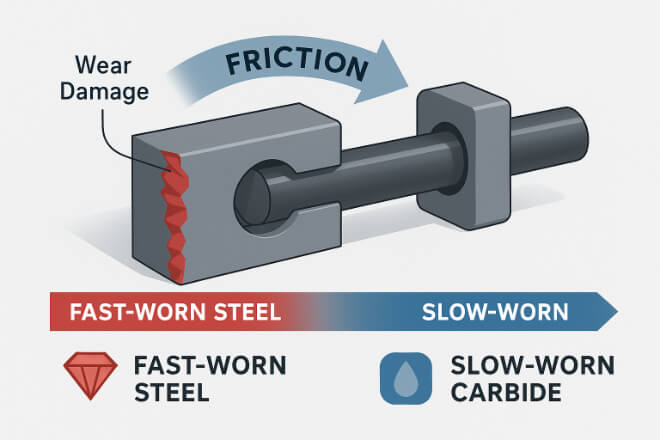

In modern industries, machinery parts face constant wear. Friction, heat, and impact often damage critical components, leading to downtime and costly repairs.

This is why wear resistance has become a key factor when choosing parts. Among the many materials available, carbide parts stand out as the most reliable option.

Their ability to resist abrasion, maintain shape, and last longer than other materials makes them the preferred choice for demanding industries.

This article explains why carbide parts outperform others, how they are made, where they are used, and why they bring the best value for companies looking to reduce costs and improve efficiency.

What Is Wear Resistance?

Wear resistance refers to a material’s ability to withstand damage caused by friction, impact, or chemical attack.

In industries such as mining, oil & gas, metalworking, and manufacturing, parts are exposed to tough conditions every day.

If materials wear out too quickly, companies must spend more on replacements and lose time in production.

Carbide, made mainly of tungsten carbide (WC) combined with a metal binder like cobalt or nickel, offers exceptional hardness.

Its unique structure allows it to resist wear much better than steel, ceramics, or other alloys. This is why carbide is often called the “ultimate wear material.”

Why Carbide Parts Outperform Others

Carbide parts have several advantages that make them stronger and more durable than alternatives.

Extreme Hardness

Tungsten carbide has a hardness close to diamond. This makes it highly resistant to abrasion, even under severe conditions.

High Wear Life

Carbide parts last several times longer than steel or ceramic parts. This reduces downtime and replacement costs.

Toughness and Strength

Unlike ceramics, carbide can resist both impact and wear. It combines hardness with toughness, which is ideal for heavy-duty applications.

Heat Resistance

Carbide maintains its hardness even at very high temperatures, making it suitable for cutting, drilling, and grinding operations.

Dimensional Stability

Carbide parts keep their precise shape and size even after long use. This ensures consistent performance in machinery.

Versatility

Carbide parts can be produced in many shapes and sizes, such as bushings, nozzles, seal rings, inserts, and balls, for use in different industries.

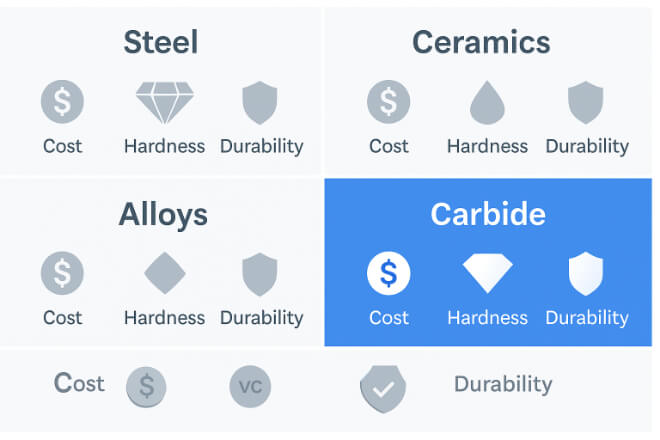

Comparison with Other Materials

To understand why carbide is superior, let’s compare it with common alternatives:

Steel Parts: Affordable but wear out quickly in high-friction environments. Frequent replacements are required.

Ceramic Parts: Hard but brittle, making them prone to cracking under impact.

Alloy Parts: Better than plain steel but still less durable than carbide.

Carbide Parts: Combine hardness and toughness, giving both long life and reliability.

In most cases, companies that switch to carbide parts see longer service life and reduced total costs, even if the initial investment is higher.

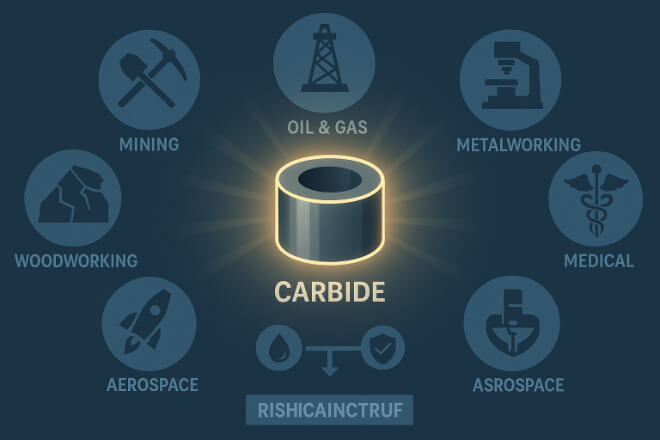

Industries That Benefit from Carbide Parts

Carbide wear parts are used in many industries where machines must operate in tough environments. Below are some examples:

Mining and Construction

Carbide tools are used in drilling, crushing, and tunneling. They extend tool life and reduce downtime in harsh working conditions.

Carbide nozzles, valve parts, and seal rings resist high pressure, corrosion, and abrasive fluids, ensuring safety and performance.

Carbide inserts and cutting tools enable faster machining, smoother finishes, and longer tool life.

Woodworking and Paper Cutting

Carbide knives and blades maintain sharp edges longer, giving better precision and reducing waste.

Aerospace and Automotive

Precision carbide parts ensure consistent performance in critical components where safety and reliability matter most.

Electronics and Medical

Carbide parts provide accuracy and long wear life in delicate and high-precision operations.

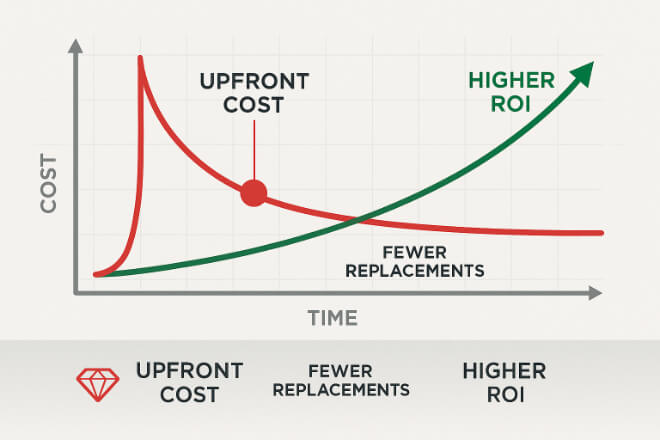

Cost Efficiency and ROI

One common concern among decision-makers is cost. Carbide parts may cost more upfront compared to steel or alloy parts.

However, when calculating return on investment (ROI), carbide always wins. The reasons are clear:

Lower Replacement Costs: Fewer parts are needed over time.

Less Downtime: Machines stay operational longer.

Improved Productivity: Consistent performance increases output.

Better Quality: Precise parts produce more accurate results.

When looking at the full lifecycle of a machine, carbide parts save money and increase profits.

How Carbide Parts Are Manufactured

The manufacturing process of carbide parts is what gives them their strength and durability.

Powder Preparation

Tungsten carbide powder is mixed with cobalt or nickel binders. This blend provides both hardness and toughness.

Pressing

The powder is pressed into the desired shape under high pressure.

Sintering

The pressed parts are heated at very high temperatures, causing the powder to fuse into a dense and hard solid.

Grinding and Finishing

Diamond grinding tools are used to give carbide parts their final shape and tight tolerances.

Optional Coating

Some parts receive a protective coating such as TiN, TiC, or DLC to further enhance wear resistance.

Environmental and Sustainability Benefits

Carbide parts are not only strong but also contribute to sustainability:

Less Waste: Longer tool life means fewer replacements and less material waste.

Lower Energy Use: Machines run more efficiently with sharp and stable parts.

Recycling: Tungsten carbide can be recycled and reused, reducing the demand for raw materials.

For companies aiming for greener operations, carbide is a smart choice.

Choosing the Right Supplier

Not all carbide parts are the same. Quality depends on raw materials, production technology, and strict quality control.

When choosing a supplier, decision-makers should look for:

Proven experience in carbide production.

Advanced R&D for material optimization.

International certifications such as ISO 9001.

Ability to provide custom solutions.

Reliable customer support and technical guidance.

Working with a trusted supplier ensures consistent performance and maximum ROI.

Conclusion

Carbide parts are the benchmark for wear resistance. Their hardness, toughness, and stability make them far superior to steel, ceramics, or alloys.

For industries where downtime is costly and reliability is critical, carbide is the material of choice.

Although the initial cost is higher, the long-term savings, improved productivity, and sustainability benefits prove that carbide parts truly outperform others.

If you want to know more details about any company, please feel free to contact us.