In industries where machines handle high pressure, fast speed, or corrosive fluids, sealing systems must be strong and reliable.

A weak seal can cause leaks, downtime, or even accidents. One of the best solutions is the tungsten carbide seal ring.

Tungsten carbide is well-known for its hardness and durability. When used in seal rings, it provides excellent protection against wear, heat, and chemicals.

For decision-makers, understanding what these rings are and how they work is key to making smart investments.

This guide explains everything you need to know about tungsten carbide seal rings—their properties, benefits, applications, and how to select the right type.

What Are Tungsten Carbide Seal Rings?

Tungsten carbide seal rings are mechanical sealing components made from tungsten and carbon compounds.

A small amount of binder (cobalt or nickel) is added to improve toughness.

These rings are used in pumps, compressors, mixers, and other rotating machines.

Their main purpose is to prevent leakage of liquids or gases while withstanding friction and pressure.

Key features:

Extreme hardness (close to diamond)

Resistance to abrasion and corrosion

Long service life under tough conditions

Stable performance at high temperature

Why Choose Tungsten Carbide for Seal Rings?

Seal rings can be made from ceramics, silicon carbide, or stainless steel. However, tungsten carbide stands out for several reasons:

Superior Hardness: Handles abrasive fluids better than most materials.

High Density: Provides strong sealing ability under heavy loads.

Thermal Stability: Works in both hot and cold environments.

Versatility: Suitable for oil, water, chemicals, and even gas sealing.

Longer Life: Reduces downtime and replacement costs.

For industries where reliability matters, tungsten carbide seal rings are often the most cost-effective choice.

Benefits of Tungsten Carbide Seal Rings

1). Longer Service Life

They can last 5–10 times longer than regular steel rings, saving money in the long run.

2). Excellent Wear Resistance

Even in abrasive liquids like slurry or chemical mixtures, they resist scratching and erosion.

3). Better Corrosion Protection

Nickel-bonded tungsten carbide rings are especially resistant to acids and seawater.

4). High Sealing Performance

They maintain tight sealing even at high pressure, reducing leak risk.

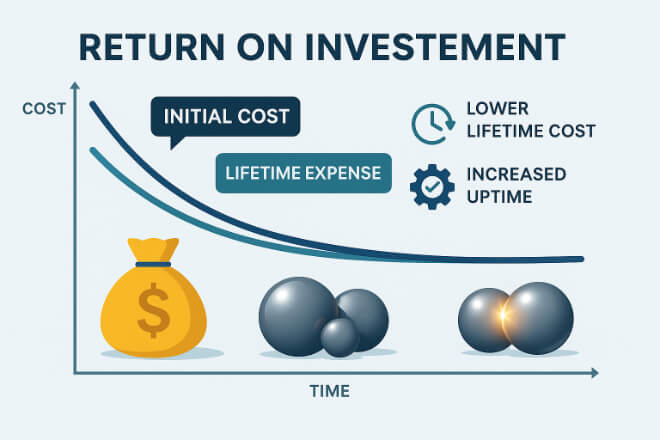

5). Cost Savings

Though initial cost is higher, fewer replacements and less downtime mean stronger ROI.

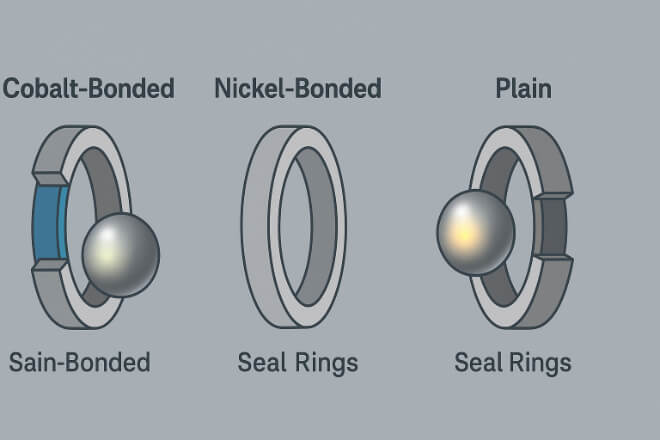

Types of Tungsten Carbide Seal Rings

1). Cobalt-Bonded Rings

More toughness

Ideal for oil and gas industry

Slightly less corrosion resistance

2). Nickel-Bonded Rings

Better against acids and seawater

Common in chemical and marine applications

3). Plain Seal Rings

Basic sealing for water and general machinery

4). Composite Seal Rings

Tungsten carbide combined with ceramics or silicon carbide

Used when extreme conditions require multi-layer protection

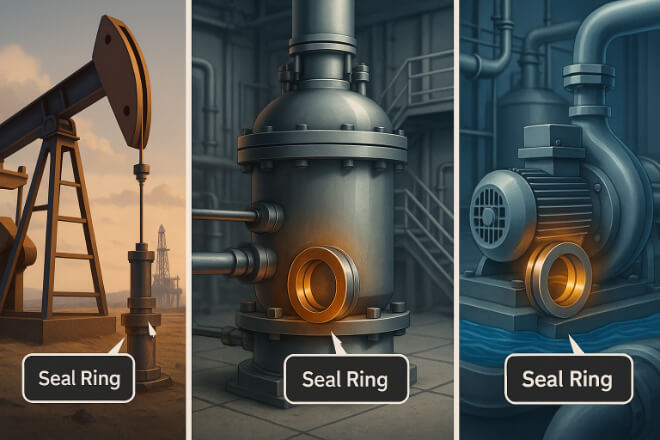

Common Applications

Oil & Gas Industry

Used in pumps and compressors where pressure is high and fluids are abrasive.

Chemical Industry

Protects systems from corrosion caused by acids and aggressive chemicals.

Marine & Offshore

Handles seawater exposure and prevents leakage in underwater pumps.

Power Plants

Ensures turbines and pumps remain leak-free under heavy stress.

Food & Pharmaceutical

Keeps mixers and pumps leak-free while meeting hygiene standards.

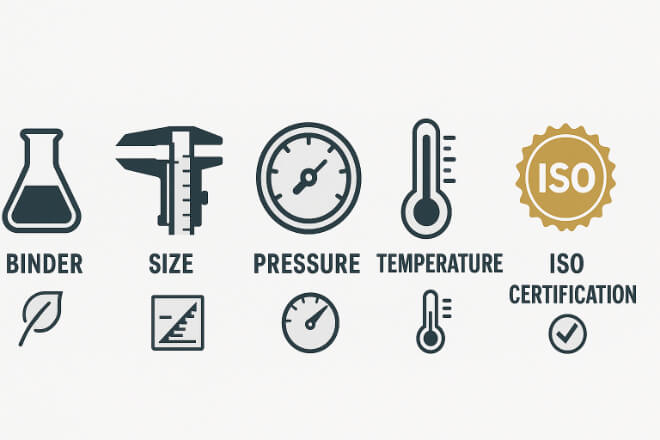

How to Select the Right Tungsten Carbide Seal Ring

When making a purchase decision, consider:

1). Binder Material:

Cobalt for toughness

Nickel for corrosion resistance

2). Size & Shape:

Must fit the pump or compressor design.

3). Operating Conditions:

Temperature range

Pressure level

Type of liquid or gas

4). Coating Options:

Some rings are coated with special layers to reduce friction.

5). Supplier Certification:

ISO or other quality standards ensure reliability.

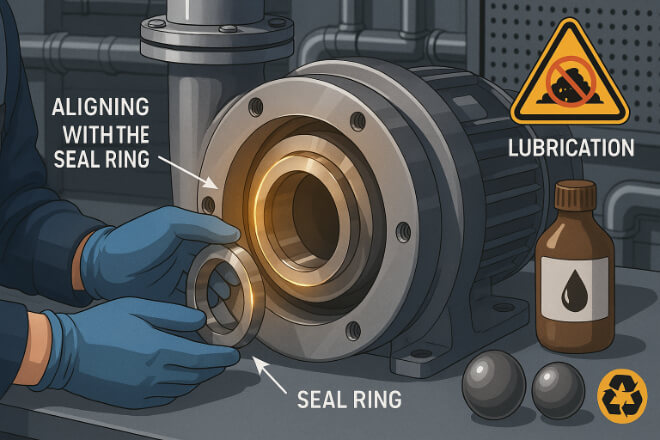

Best Practices for Using Seal Rings

Correct Installation: Misalignment reduces lifespan.

Proper Lubrication: Essential for reducing friction and heat.

Regular Inspection: Look for cracks, scratches, or uneven wear.

Avoid Contamination: Dirt or sand can quickly damage the ring.

Replace on Time: Don’t wait for total failure; plan preventive replacement.

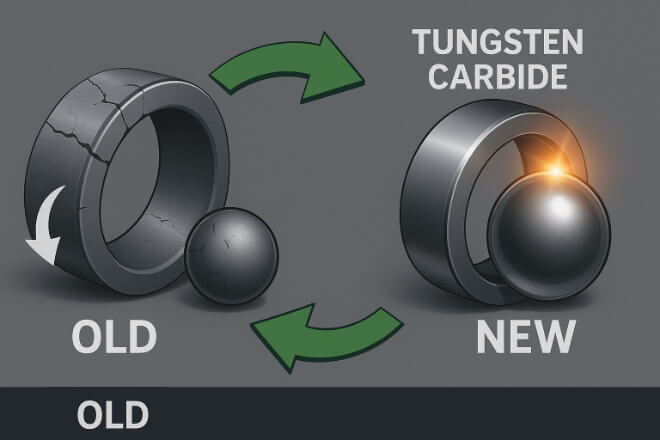

Maintenance and Replacement

Even the strongest seal ring wears out eventually.

Inspection Frequency: Every 2–4 weeks in critical operations.

Signs of Wear: Increased leakage, noise, or vibration.

Replacement Policy: Always replace with the same grade and dimensions.

Recycling: Worn tungsten carbide rings can be recycled, lowering costs.

Cost Benefits for Companies

Lower Maintenance Cost: Fewer replacements needed.

Reduced Downtime: Machines stay running longer.

Safer Operations: Stronger seals reduce accident risks.

Higher ROI: Savings over time outweigh higher upfront price.

For decision-makers, the financial advantage is clear: fewer failures mean more productivity and stronger profitability.

Case Studies

1). Oil Drilling Company

After switching to tungsten carbide seal rings, the company reduced downtime by 40% because seals lasted longer in abrasive drilling fluids.

2). Chemical Plant

Nickel-bonded rings resisted acid corrosion, cutting replacement frequency in half.

3). Marine Pump Manufacturer

Seal rings survived longer in seawater conditions, improving customer satisfaction and lowering warranty claims.

How to Source Tungsten Carbide Seal Rings

When sourcing, decision-makers should:

Select suppliers with proven industry experience

Confirm ISO and quality certifications

Ask about local stock for faster delivery

Request custom designs if unique sizes are required

Check after-sales service for technical support

For more supplier information, visit Retopz.com to explore trusted global options.

Conclusion

Tungsten carbide seal rings are the backbone of reliable sealing systems. Their hardness, resistance to wear, and corrosion protection make them the top choice for demanding industries.

For company leaders, choosing tungsten carbide means stronger performance, longer service life, and lower overall costs.

Whether in oil & gas, chemical, marine, or power industries, these rings provide the security and efficiency businesses need.

If you want to know more details about any company, please feel free to contact us.