Tungsten carbide wear components are used in industries like mining, oil and gas, manufacturing, and metalworking because of their high hardness, wear resistance, and long service life.

Even though they are much stronger than steel, they will eventually wear down or fail.

For decision-makers, knowing when to replace these components is key to avoiding costly downtime, protecting other machine parts, and keeping production efficient.

In this guide, we’ll explain the signs that replacement is needed, how to carry it out correctly, and how to extend the lifespan of new components.

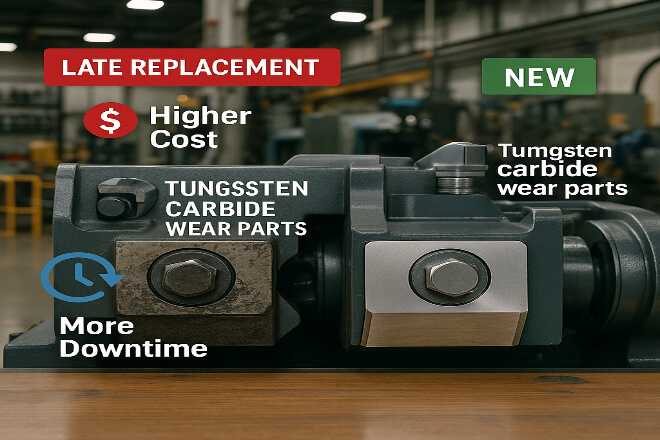

Why Replacement Timing Matters

Replacing tungsten carbide wear parts too late can lead to:

Unplanned downtime

Higher repair costs

Damage to other parts

Lower product quality

Replacing too early, however, can waste resources. A balance is needed—monitor wear parts regularly and replace them at the optimal time.

Common Signs a Component Needs Replacement

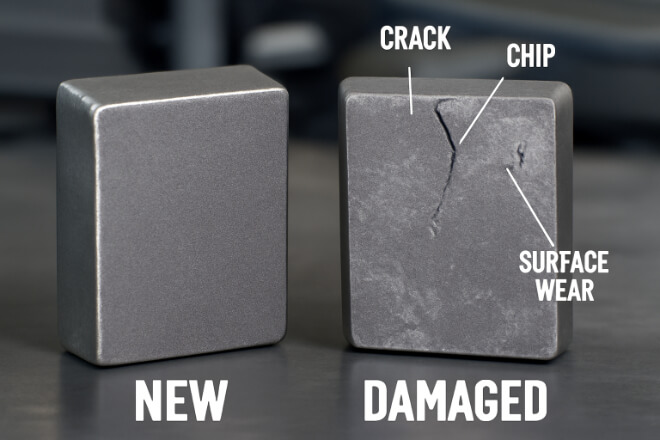

Excessive Wear

If the working surface has lost significant material thickness or shape, it may no longer function effectively. This can lead to misalignment, overheating, or reduced cutting performance.

Cracks or Chipping

Small cracks in tungsten carbide can quickly grow under stress, leading to sudden failure. Any visible chipping is a strong indicator that replacement is needed.

Performance Drop

If your machinery requires more energy, produces lower-quality output, or slows down, worn wear parts may be the cause.

Increased Vibration or Noise

Worn parts often cause imbalance, resulting in vibration or unusual noise during operation.

Factors That Affect Replacement Intervals

Different working conditions change how often wear components need replacement.

| Factor | Impact on Wear Life |

|---|---|

| Material Processed | Abrasive materials like sand or glass shorten lifespan |

| Operating Temperature | High heat can weaken carbide and cause cracks |

| Load and Pressure | Higher loads accelerate fatigue |

| Lubrication Quality | Poor lubrication increases friction and wear |

| Shock and Impact | Frequent impacts can chip carbide edges |

How to Inspect Tungsten Carbide Wear Parts

Regular inspections are the key to timely replacement.

Step 1 – Visual Check

Look for cracks, chips, discoloration, or uneven wear.

Step 2 – Dimensional Measurement

Use calipers or micrometers to measure thickness, length, or diameter and compare to the original specs.

Step 3 – Performance Data Review

Track machine efficiency, power consumption, and output quality.

Step 4 – Maintenance Records

Log wear rates over time to predict the replacement schedule.

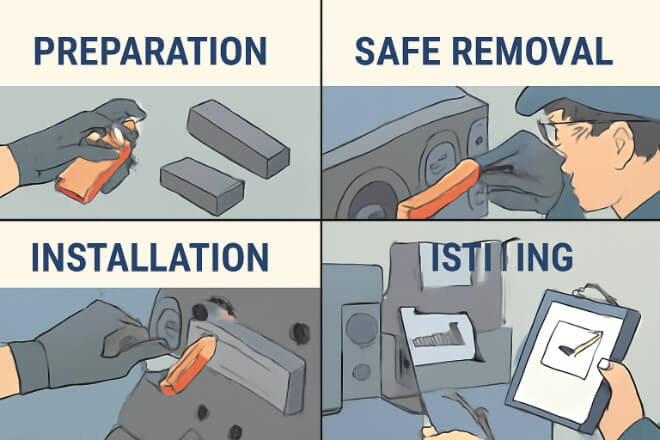

Replacement Process: Step-by-Step

1). Prepare the New Component

Make sure it is the correct grade and size.

Check manufacturer specifications.

Inspect for any defects before installation.

2). Safe Removal of Old Component

Shut down and lock out the machine.

Use the correct tools to avoid damaging surrounding parts.

Dispose of worn components according to recycling guidelines.

3). Installation of New Component

Follow torque and alignment instructions from the manufacturer.

Use proper lubrication if required.

Avoid excessive force during fitting.

4). Post-Installation Checks

Test run the machine at low speed.

Monitor for noise, vibration, or leaks.

Re-check fasteners after the first few hours of operation.

Recycling Worn Tungsten Carbide

Tungsten carbide can be recycled to recover valuable tungsten and cobalt. Partnering with a reliable recycling company can:

Reduce costs

Lower environmental impact

Ensure compliance with waste regulations

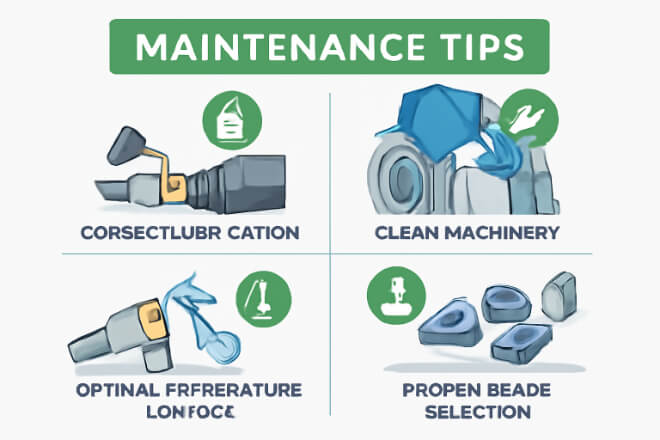

Extending the Life of Wear Components

The longer your components last, the fewer replacements you need.

Choose the Right Grade – Different grades of tungsten carbide are designed for specific conditions.

Improve Lubrication – Use the correct lubricant for your environment.

Control Operating Conditions – Avoid unnecessary impacts and overheating.

Regular Maintenance – Clean, inspect, and adjust machinery often.

Maintenance & Replacement Checklist

| Check Item | Frequency | Action |

|---|---|---|

| Visual Inspection | Weekly | Look for cracks, chips, or discoloration |

| Dimensional Measurement | Monthly | Compare with original specifications |

| Lubrication | Daily/As needed | Ensure correct type and cleanliness |

| Performance Review | Monthly | Track output quality and energy usage |

| Replacement | As required | Follow manufacturer recommendations |

Working with Trusted Suppliers

The right supplier can help:

Analyze wear patterns

Suggest better carbide grades

Provide precision-made replacements

Offer faster delivery for urgent replacements

Conclusion

For decision-makers in industries that depend on tungsten carbide wear components, knowing when and how to replace parts is critical.

Delaying replacement risks equipment damage and production loss, while replacing too early wastes resources.

By monitoring wear indicators, following a proper replacement process, and working with trusted suppliers, companies can reduce downtime, cut maintenance costs, and extend the overall life of their equipment.

If you want to know more details about any company, please feel free to contact us.