In industries where machines face friction, abrasion, heat, and pressure, material choice is critical. Wear parts are the first line of defense in protecting equipment from damage.

The wrong choice can lead to frequent breakdowns, costly downtime, and unsafe operations.

Tungsten carbide is one of the most reliable materials for wear parts. It offers exceptional hardness, long service life, and resistance to extreme working conditions.

For decision-makers, understanding why tungsten carbide is the right choice helps in making better investments and supplier decisions.

This article explains why tungsten carbide is the top choice for wear parts, covering its unique properties, industrial applications, cost advantages, and long-term value.

What Is Tungsten Carbide?

Tungsten carbide is a composite material made of:

Tungsten carbide grains (WC) – very hard ceramic particles.

Binder metal (usually cobalt or nickel) – adds toughness and holds grains together.

The result is a material that combines the hardness of ceramics with the toughness of metals.

Compared to steel, tungsten carbide is much harder and lasts many times longer.

For wear parts, this means superior performance and longer life under extreme stress.

The Key Properties of Tungsten Carbide

The success of tungsten carbide in wear parts comes from its unique physical properties:

High Hardness – HRA 89.5–92.5, close to diamond on the hardness scale.

Excellent Wear Resistance – resists abrasion from metals, rocks, sand, and chemicals.

High Density – 14.5–15.0 g/cm³, giving strong impact resistance.

High Compressive Strength – withstands extreme pressure without deformation.

Thermal Stability – maintains hardness at high operating temperatures.

Corrosion Resistance – with special binders or coatings, it resists chemicals and fluids.

These properties make tungsten carbide ideal for parts that need precision, durability, and reliability.

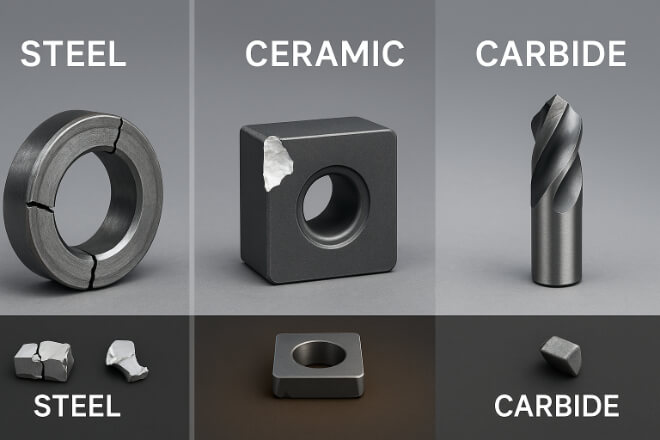

Advantages Over Other Materials

Why choose tungsten carbide instead of steel, ceramics, or alloys?

Compared to Steel: Tungsten carbide lasts 5–10 times longer and resists abrasion better.

Compared to Ceramics: Carbide is less brittle and offers better toughness.

Compared to Coated Alloys: Carbide performs better in extreme wear and high-pressure environments.

In short, tungsten carbide offers the best balance between hardness and toughness, giving decision-makers confidence in high-demand applications.

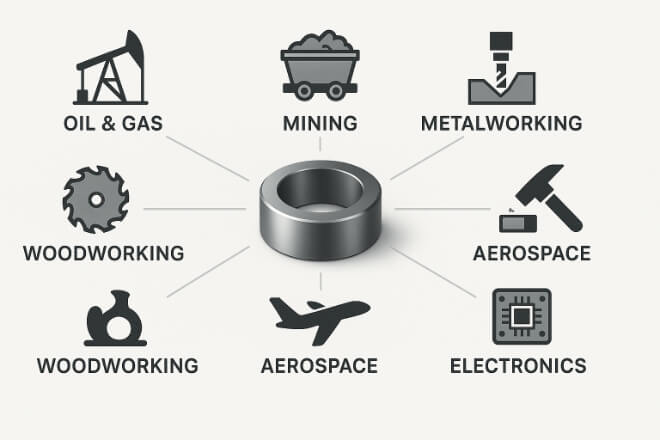

Applications in Heavy Industries

Tungsten carbide wear parts are used in many industries where durability is essential:

Oil and Gas Industry – valve seats, sleeves, nozzles, seals for drilling and pumping systems.

Mining and Construction – drill bits, crusher hammers, boring machine tools, wear plates.

Metalworking – cutting inserts, dies, forming tools, saw tips.

Woodworking and Paper Cutting – knives, blades, inserts, and trimmer parts.

Aerospace and Automotive – high-precision tools, seals, and bearings.

Electronics – micro drills, punches, dies, and fine cutting parts.

Wherever wear resistance and precision are critical, tungsten carbide provides the solution.

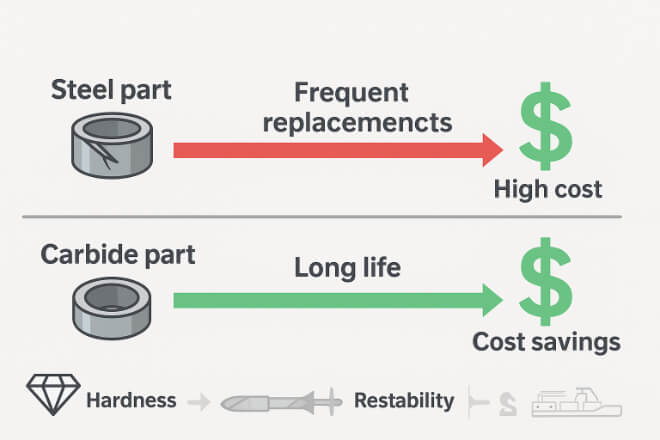

Cost Efficiency and Long-Term Value

At first, tungsten carbide parts are more expensive than steel or simple alloys. However, decision-makers should look at total cost of ownership (TCO) instead of purchase price.

Longer life = fewer replacements.

Less downtime = more production time.

Reduced maintenance = lower labor cost.

Better machine protection = less damage to expensive equipment.

Over time, tungsten carbide wear parts save money and increase productivity, making them a smart business investment.

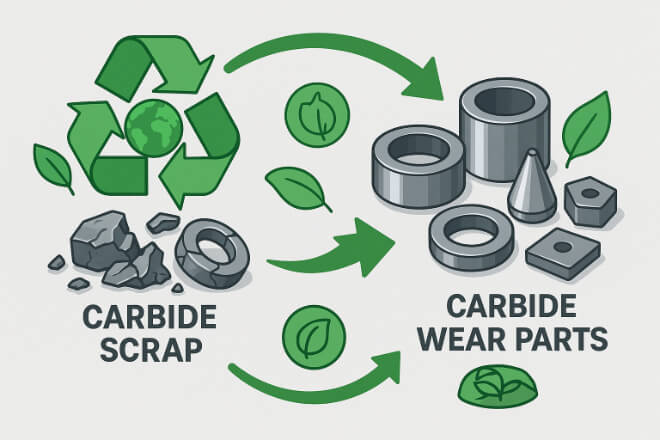

Environmental and Sustainability Benefits

Sustainability is now a priority in global industries. Tungsten carbide helps companies meet these goals by:

Reducing waste – fewer part replacements means less scrap.

Recycling – worn carbide can be collected and recycled into new parts.

Energy savings – longer tool life reduces production interruptions.

This makes tungsten carbide not only a technical choice but also an environmentally responsible one.

Supplier Considerations for Decision-Makers

When choosing tungsten carbide wear parts, selecting the right supplier is as important as choosing the material itself. Decision-makers should evaluate suppliers based on:

ISO certification and quality management systems.

Testing and inspection reports (hardness, density, microstructure).

Proven track record in delivering carbide products to similar industries.

Ability to provide custom designs for special applications.

After-sales service and technical support.

Working with reliable suppliers ensures the authenticity, performance, and consistency of tungsten carbide wear parts.

Case Example: Mining Application

In mining operations, drill bits and picks face constant rock impact and abrasion. Steel tools often last only a few hours before failure.

A tungsten carbide drill insert, however, can last five to ten times longer, reducing tool replacement frequency and downtime. This directly translates into higher productivity and lower cost per ton of ore mined.

This example proves why tungsten carbide is the logical choice for industries where wear resistance is critical.

Conclusion

Tungsten carbide is the best choice for wear parts because it offers unmatched hardness, superior wear resistance, high toughness, and long-term value. For decision-makers, it provides:

Reduced downtime

Lower long-term costs

Better performance in extreme conditions

Sustainability and recycling advantages

In industries where efficiency, safety, and reliability matter, choosing tungsten carbide for wear parts is not just a material decision – it is a strategic business choice.

If you want to know more details about any company, please feel free to contact us.