In modern manufacturing, choosing the right cutting tool is very important. Tools must be strong, precise, and last a long time. Tungsten carbide cutting tools are trusted by industries because of one big reason — superior wear resistance.

In this blog, we explain what makes tungsten carbide so tough, why it lasts longer than other materials, and how it helps in different industries. If you’re looking for high-performance tools, this article will help you understand why tungsten carbide is the smart choice.

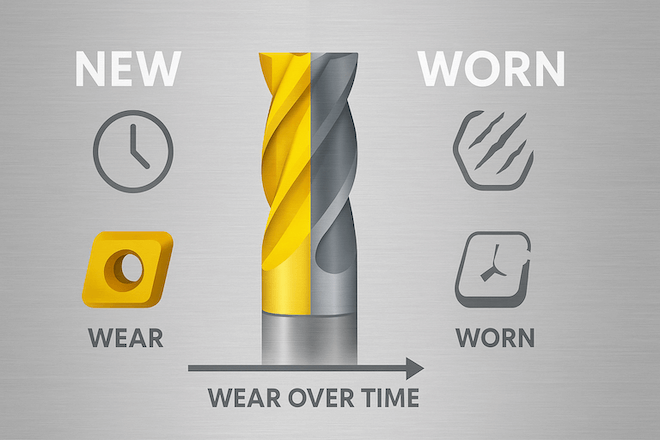

What Is Wear Resistance?

Wear resistance means how well a tool can stay strong and sharp when used over time. When tools cut, drill, or grind materials, they rub against surfaces. This causes wear – a slow breakdown of the tool.

Materials with high wear resistance do not get dull or damaged quickly. This is important for saving costs, reducing downtime, and making clean, precise cuts.

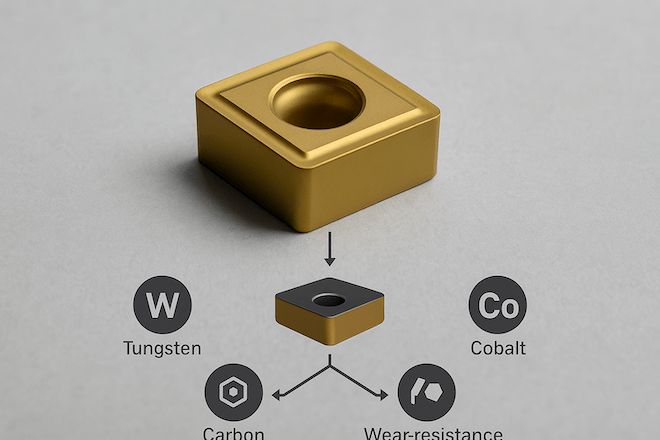

What Is Tungsten Carbide?

Tungsten carbide (WC) is a compound made from tungsten (W) and carbon (C). It is one of the hardest materials used in cutting tools. Sometimes, a binder like cobalt (Co) is added to make it tougher.

Tungsten carbide is:

Harder than steel

Very dense

Strong at high temperatures

These properties help it resist wear much better than traditional tool steels like High-Speed Steel (HSS).

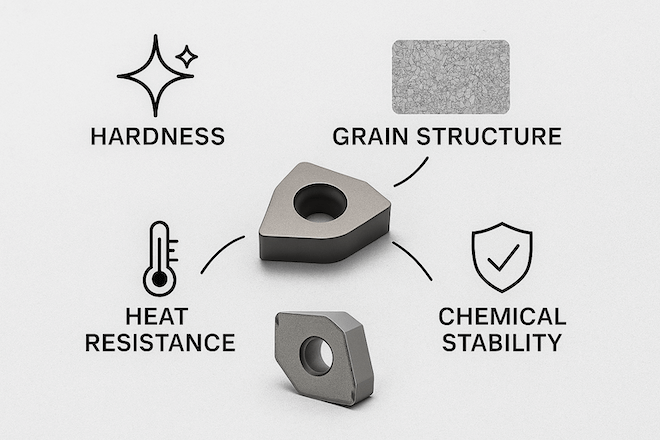

Why Tungsten Carbide Tools Resist Wear So Well

There are several reasons why tungsten carbide cutting tools are more resistant to wear than others:

1. High Hardness

Tungsten carbide is extremely hard — reaching up to HRA 92 on the Rockwell scale. This allows the tool to cut hard materials like stainless steel, titanium, and cast iron without losing its edge.

Harder tools = slower wear = longer tool life.

2. Strong Grain Structure

The microstructure of tungsten carbide includes tightly packed grains and a tough binder. This helps reduce chipping and cracking, especially in heavy-duty operations.

You can explore different grades and grain sizes on the carbide grades guide from Retop.

3. Heat Resistance

Tungsten carbide keeps its strength even at high temperatures. It doesn’t soften easily during high-speed cutting. This is important when machining hard metals or using tools continuously.

4. Coating Compatibility

Tungsten carbide tools can be coated with PVD, CVD, or diamond coatings. These coatings give even more protection against friction, wear, and heat.

5. Chemical Stability

WC is resistant to corrosion, oxidation, and chemical reactions. This makes it ideal for cutting tools in wet, acidic, or corrosive environments.

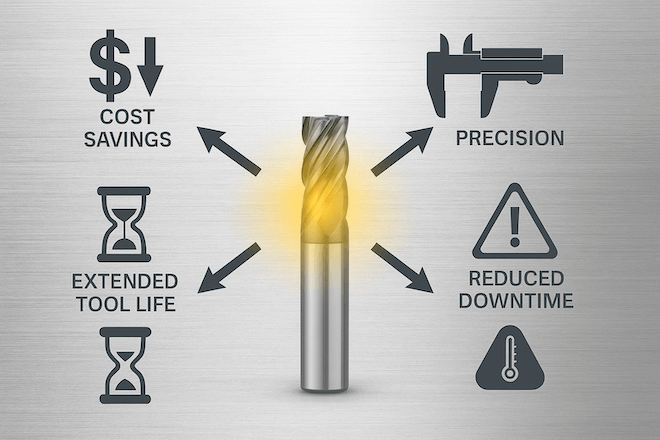

Benefits of Using Wear-Resistant Carbide Tools

Using tungsten carbide tools with strong wear resistance offers many benefits:

✅ Longer tool life

✅ Fewer tool changes

✅ Higher production speed

✅ Better surface finish

✅ Lower overall tooling cost

Want to reduce costs and downtime? Try Retop’s carbide cutting tools for consistent performance in harsh working conditions.

Real-World Applications of Tungsten Carbide Cutting Tools

Carbide tools are used in many industries that require high wear resistance:

1. Aerospace Industry

Used to cut titanium, nickel alloys, and composites with accuracy and consistency.

2. Automotive Industry

Helps machine engine parts, transmission components, and brake rotors faster and cleaner.

3. Oil & Gas Industry

Great for drilling hard rock and abrasive environments. See carbide wear parts from Retop.

4. Mold and Die Manufacturing

Precision machining of steel molds using carbide end mills and inserts.

5. Electronics and Medical

Used for micromachining with sharp edges that stay accurate even at small sizes.

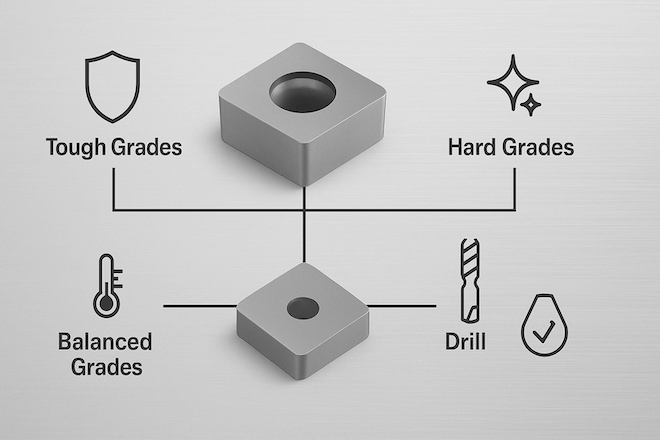

How to Choose the Right Carbide Grade for Wear Resistance

Different jobs need different carbide grades. Here are some simple tips:

| Application | Suggested Grade | Focus |

|---|---|---|

| General Cutting | YG6, YG8 | Balanced hardness and toughness |

| High Hardness | YG10X, YG15 | High wear resistance |

| Heavy Impact | YG20, YG25 | More toughness, less wear resistance |

| Precision | Sub-micron grades | Fine grain, sharp edge retention |

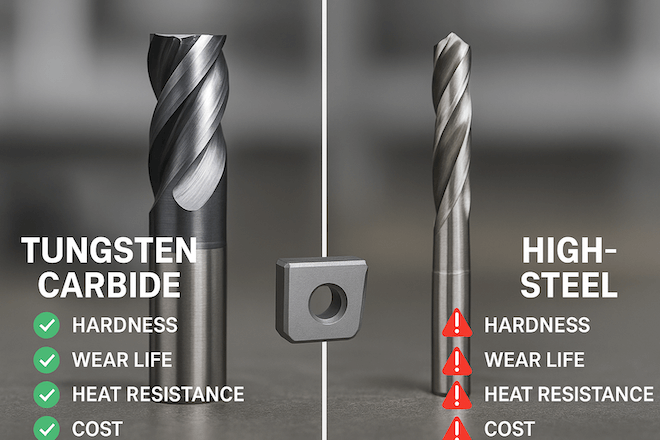

Summary: Why Tungsten Carbide Outperforms Other Materials

Let’s compare:

| Property | Tungsten Carbide | HSS / Tool Steel |

|---|---|---|

| Hardness | Very high (HRA 90–92) | Moderate |

| Heat Resistance | Excellent | Medium |

| Wear Life | 3–10x longer | Shorter |

| Cost | Higher upfront | Lower |

| Value | Better in long term | Frequent replacement |

If you’re machining hard, abrasive, or high-volume materials, tungsten carbide is the best choice.

Where to Buy High-Quality Tungsten Carbide Cutting Tools?

At Retop, we specialize in high-performance carbide tools designed for long wear life and stable cutting. We offer:

✅ Custom tool solutions

✅ Small batch flexibility

✅ ISO 9001 certified production

✅ 14+ years of manufacturing experience

👉 Visit our homepage: www.retopz.com

Or browse popular tools like:

Final Thoughts

Tungsten carbide cutting tools are trusted across industries for their superior wear resistance. Their hardness, heat resistance, and long life make them ideal for tough jobs where precision and durability matter.

Investing in quality carbide tools means fewer problems, lower long-term costs, and better results — every time.