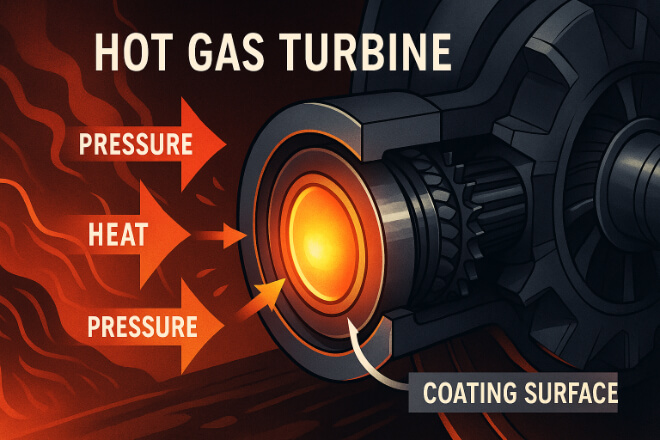

In gas turbines, compressors, and energy systems, sealing at high temperature is one of the biggest engineering challenges.

Gas at hundreds of degrees can damage equipment, cause leaks, and reduce efficiency. For these extreme conditions, companies need sealing solutions that are both tough and reliable.

This is where tungsten carbide seal rings stand out. Known for their hardness and durability, these rings also offer excellent performance in high-temperature gas sealing.

For decision-makers in oil, gas, power, and aerospace industries, choosing tungsten carbide seal rings ensures safety, uptime, and cost savings.

The Challenge of High-Temperature Gas Sealing

When machines handle hot gas, seals face three major problems:

Thermal Stress: Heat can weaken or deform many materials.

Wear and Friction: Hot gas increases friction, causing faster wear.

Chemical Attack: At high temperature, gases may become corrosive.

If the seal fails, it can lead to leakage, shutdowns, or safety risks. Standard materials like steel or ceramics cannot always survive these conditions.

What Makes Tungsten Carbide Suitable for High Temperatures?

Tungsten carbide has unique properties that make it ideal for hot environments:

Hardness: Almost as hard as diamond, it resists wear even at high heat.

Thermal Stability: Keeps its shape and strength at high temperatures.

Corrosion Resistance: Nickel-bonded grades resist chemical gases.

Toughness: Cobalt-bonded grades resist cracking under load and shock.

These properties combine to give reliable sealing where other materials fail.

Key Properties for High-Temperature Gas Sealing

1). Hardness and Wear Resistance

Even at high heat, tungsten carbide maintains hardness, resisting scratches and erosion from gas particles.

2). Thermal Stability

Unlike steel, which can lose strength, tungsten carbide stays stable under continuous high-temperature operation.

3). Low Friction Surface

Polished tungsten carbide rings reduce friction, preventing overheating and improving efficiency.

Nickel-bonded tungsten carbide resists corrosive hot gases found in chemical plants and refineries.

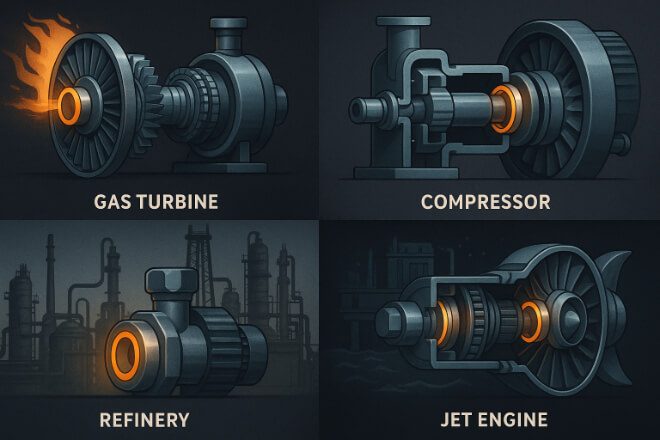

Applications of Tungsten Carbide Seal Rings in High-Temperature Gas Systems

1). Gas Turbines

Turbines in power plants run at very high temperatures. Tungsten carbide rings ensure tight seals, improving efficiency and preventing leaks.

2). Compressors

Gas compressors in oil and gas industries handle hot gases under pressure. Seal rings prevent gas escape and reduce energy loss.

3). Refining and Petrochemical Plants

Tungsten carbide rings resist hot, corrosive gases produced in refining and chemical reactions.

4). Aerospace Engines

High-performance jet engines require seals that can handle extreme heat. Tungsten carbide provides durability and reliability.

Benefits for High-Temperature Operations

Longer Service Life: Resists wear and heat better than steel or ceramic seals.

Improved Safety: Strong seals reduce risk of leaks or accidents.

Lower Maintenance Costs: Fewer failures mean fewer shutdowns.

Better Efficiency: Reduced friction helps machines run smoother.

Comparison with Other Seal Materials

| Material | Strengths | Weaknesses |

|---|---|---|

| Stainless Steel | Affordable, easy to make | Loses strength at high heat, wears faster |

| Silicon Carbide | Good corrosion resistance | Brittle, cracks under shock load |

| Ceramics | High hardness, handles heat | Fragile, breaks under impact |

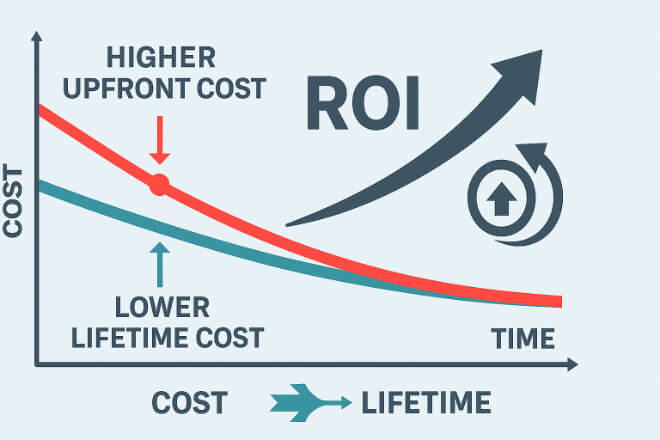

| Tungsten Carbide | Excellent hardness, thermal stability, and toughness | Higher upfront cost |

Case Studies

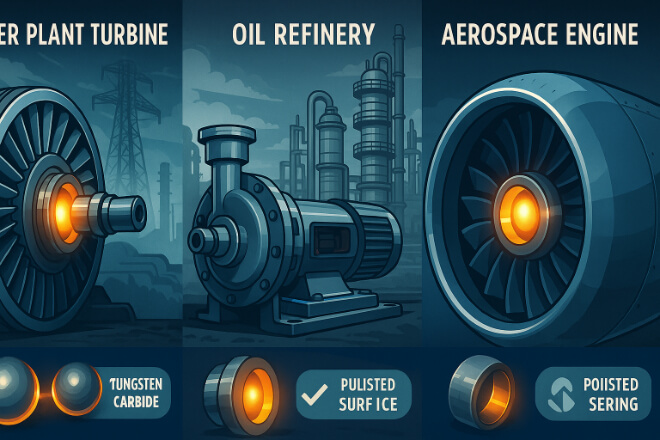

1). Power Plant Turbine

A plant replaced steel seals with tungsten carbide rings. Result: fewer breakdowns and better energy efficiency.

2). Oil Refinery

Nickel-bonded tungsten carbide rings resisted hot, corrosive gases, extending service life by 60%.

3). Aerospace Engines

Tungsten carbide seals improved safety and durability under high-temperature jet engine conditions.

How to Select the Right Tungsten Carbide Seal Ring for Gas Sealing

1). Binder Choice:

Nickel for corrosive gases

Cobalt for high load and shock

2). Surface Finish:

Polished surfaces for reduced friction

3). Operating Conditions:

Match grade to temperature and pressure range

4). Supplier Quality:

Choose ISO-certified suppliers with proven experience

Maintenance and Replacement in High-Temperature Systems

Even with tungsten carbide, inspection is needed:

Check for cracks or wear regularly

Replace seals before full failure

Ensure replacements match grade and dimensions

Recycle old tungsten carbide to reduce costs

Cost and ROI for Decision-Makers

While tungsten carbide seal rings cost more upfront, the long-term value is higher:

5–10x longer lifespan

Reduced downtime in critical systems

Safer and more reliable operations

Stronger return on investment

Conclusion

Tungsten carbide seal rings are the best choice for high-temperature gas sealing.

Their combination of hardness, toughness, and thermal stability makes them ideal for turbines, compressors, refineries, and aerospace engines.

For decision-makers, this means fewer failures, safer operations, better efficiency, and lower long-term costs.

If you want to know more details about any company, please feel free to contact us.