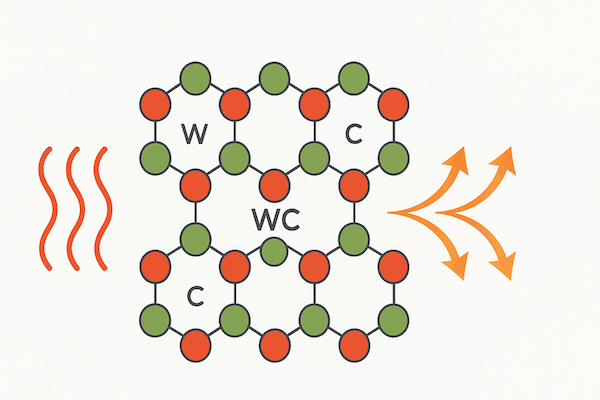

碳化钨行业的热稳定性:解释性概述

简介 在先进材料领域,碳化钨 (WC) 以其出色的硬度、耐磨性和高熔点脱颖而出。这些特性使其成为采矿、航空航天、制造业和汽车行业等各种行业不可或缺的材料。在其众多优势特性中,热稳定性是一项关键特性,对性能有重大影响 […]

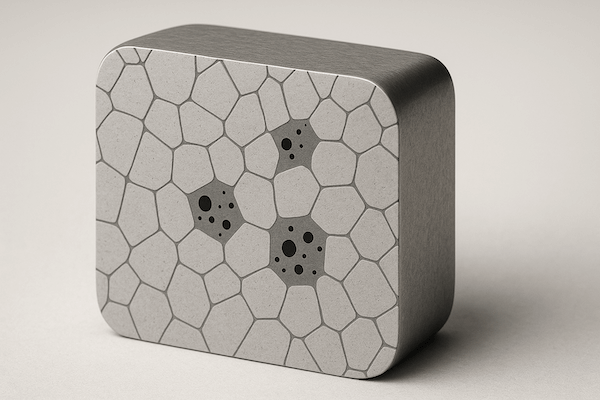

碳化钨行业中的孔隙率:解释性概述

简介:孔隙率是材料科学中的一个重要概念,尤其适用于工业刀具中使用的高性能材料,例如碳化钨 (WC)。尽管孔隙率常常被忽视,但它在决定硬质合金刀具的机械强度、耐磨性和整体可靠性方面起着至关重要的作用。本文将深入探讨孔隙率的概念、形成机制以及[…]

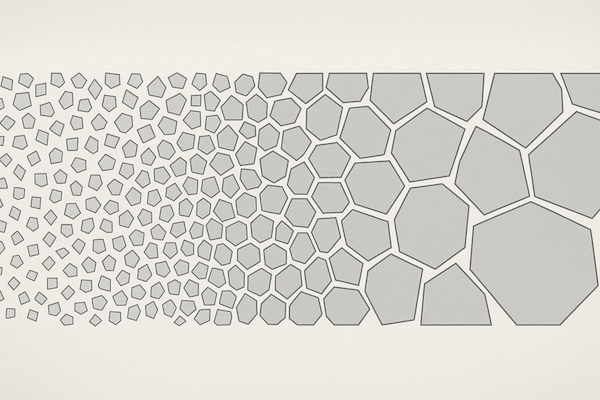

了解碳化钨刀具的晶粒尺寸

在先进材料和刀具领域,一个经常出现的术语是“晶粒尺寸”。虽然这听起来像是只有冶金学家才会关心的细节,但晶粒尺寸对于采矿、机械加工、石油天然气和精密制造行业使用的碳化钨刀具的性能、强度和耐用性起着至关重要的作用。那么——[…]

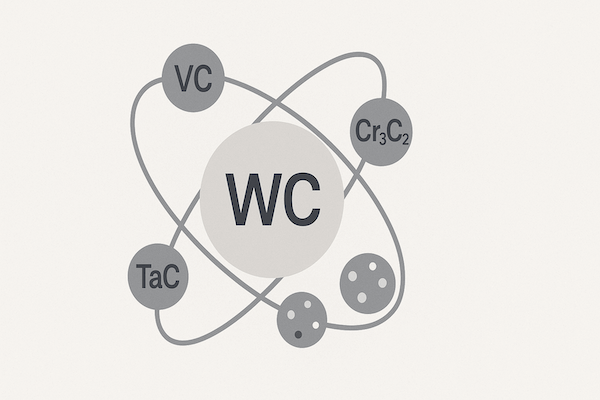

了解碳化钨刀具中的合金元素

碳化钨刀具以其卓越的硬度、耐磨性和耐受极端工况的能力而闻名。然而,这种卓越性能的背后不仅仅在于WC和钴,更在于精心挑选的合金元素。这些微量添加元素虽然含量微乎其微,但却对刀具性能有着巨大的影响,[…]