如何磨锐和修复碳化钨切削刀具

碳化钨切削刀具以其卓越的耐用性和持久的刃口保持性而闻名。然而,即使是最坚固的刀具,在日常使用中也会磨损。与其每次都更换钝的刀具,不如经常进行磨锐或修复,以恢复其性能并延长使用寿命。这不仅节省成本,还有助于维护[…]

延长碳化钨切削刀具寿命的维护技巧

碳化钨切削刀具以其强度、耐用性和耐磨性而闻名。但即使是最坚固的刀具,如果没有适当的保养,也无法长久使用。如果您想最大限度地利用您的碳化钨刀具,并避免浪费时间和金钱,就需要养成良好的维护习惯。本指南将为您分解一些简单实用的技巧,帮助您延长刀具使用寿命[…]

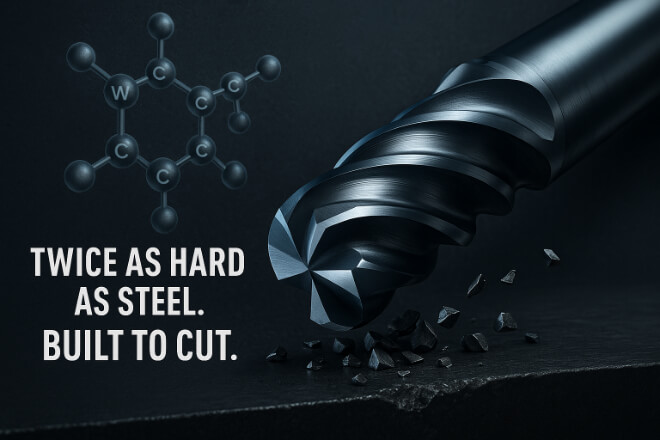

为什么碳化钨切削刀具具有优越的耐磨性

在现代机械加工中,刀具磨损是最大的挑战之一。刀具磨损过快会导致表面质量差、生产速度慢、成本上升。因此,耐磨性至关重要——而这正是碳化钨切削刀具真正闪耀光芒的地方。碳化钨不仅仅是一种刀具材料。它是最坚硬、最耐用的刀具之一[…]

了解碳化钨刀具应用的等级

说到切削刀具,碳化钨是追求强度、速度和可靠性的专业人士的首选材料。但并非所有碳化钨刀具都生来平等。您选择的碳化钨等级会极大地影响刀具的性能和使用寿命。无论您是切削铝、钢还是复合材料,使用[…]

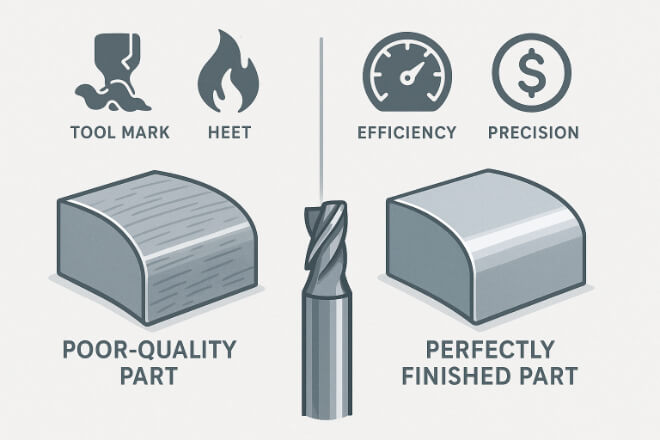

碳化钨切削刀具如何提高加工效率和精度

在现代机械加工中,速度和精度至关重要。无论您是在数控车间生产零件,还是管理大规模生产,切削刀具的质量都会直接影响产量、成本和产品质量。正因如此,越来越多的行业正在从传统刀具转向碳化钨切削刀具。但它们究竟有何特别之处?[…]

碳化钨切削刀具在各行业的主要应用

碳化钨刀具以其超强硬度、极佳的耐用性和出色的刀刃保持性而闻名。这些刀具广泛应用于从航空航天到木工等众多行业,因为它们能够胜任普通钢制刀具无法胜任的复杂加工。在本文中,我们将探讨使用碳化钨刀具的顶级行业,以及这些刀具为何如此受欢迎[…]

碳化钨与高速钢:哪种切削刀具更好?

说到切削刀具,两种材料总是被反复提及:碳化钨和高速钢 (HSS)。如果您想知道哪种材料更适合您的工作,答案取决于您更看重什么——速度、耐用性还是预算。但如果您想要耐用的刀具、更佳的性能和更快的加工速度,碳化钨无疑是最佳选择[…]

如何根据您的应用选择合适的碳化钨切削刀具

碳化钨刀具坚固耐用、快速可靠,但选择合适的刀具并非易事。面对琳琅满目的刀具类型、涂层和用途,感到不知所措是正常的,尤其是在您并非刀具专家的情况下。在本指南中,我们将向您展示如何根据工作需求选择合适的碳化钨刀具。[…]

在数控加工中使用碳化钨切削刀具的好处

在数控加工中,精度和生产效率至关重要。无论您是生产单个高精度零件,还是运行整条生产线,切削刀具都发挥着至关重要的作用。有一种材料脱颖而出:碳化钨。越来越多的机加工厂和制造商正在转向使用碳化钨切削刀具——这是有充分理由的。这些刀具 […]

什么是碳化钨切削刀具?新手入门指南

在当今快速发展的制造业中,切削刀具需要坚固、精准、耐用。这正是碳化钨切削刀具的用武之地。这些刀具几乎应用于所有行业——汽车、航空航天、建筑、石油和天然气等等——因为它们能够轻松切割最坚硬的材料。如果您是机械加工新手,或者只是好奇[…]