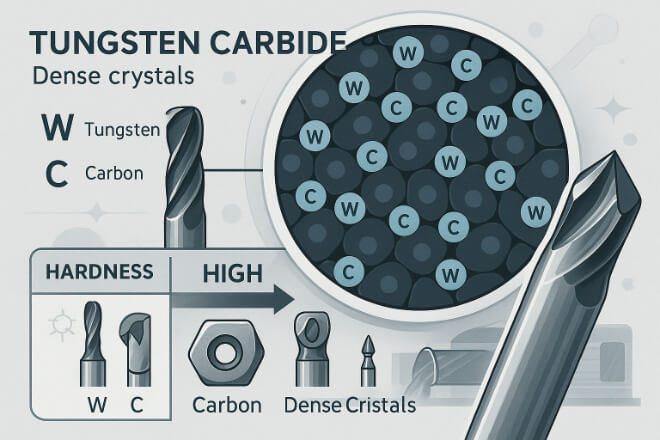

工作原理 – 碳化钨切削刀具

碳化钨刀具在现代机械加工中至关重要。这些刀具以其卓越的硬度和强度而闻名,广泛应用于从航空航天零件到汽车零部件等各种领域。但它们究竟是如何工作的?是什么让它们如此可靠?为什么它们比其他刀具材料更受青睐?在本篇博客中,我们将为您揭晓答案 […]

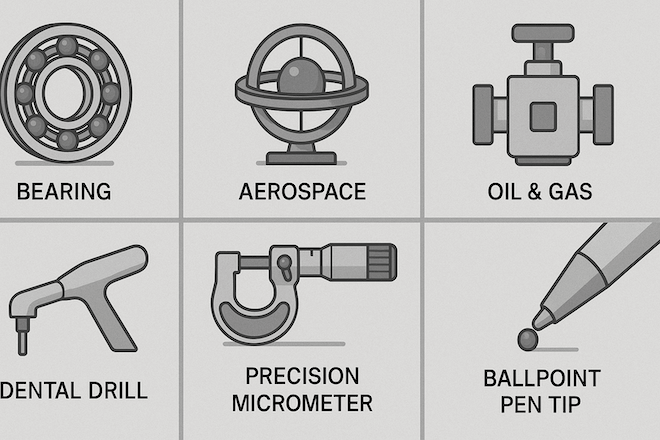

碳化钨 – 切削刀具:工业和科学

在现代制造和精密加工领域,碳化钨切削刀具至关重要。无论您身处航空航天、汽车、石油天然气还是科学研究领域,这些刀具都能提供高性能、长寿命和始终如一的加工效果。但为什么碳化钨如此强大的材料?这些刀具如何服务于工业和科学领域?[…]

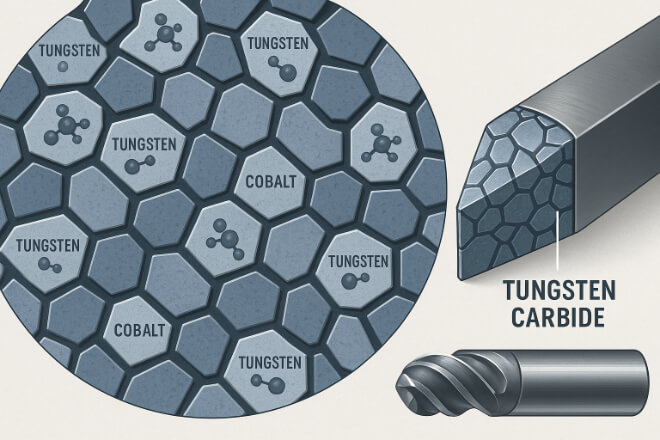

刀具领域中的硬质合金与碳化钨

说到制造业使用的切削刀具,“硬质合金”这个词经常被提及。但它究竟是什么意思呢?更重要的是,“硬质合金”和“碳化钨”之间有什么区别?如果您是机械加工或工具行业的决策者,了解切削刀具背后的材料是更好地选择刀具的关键[...]

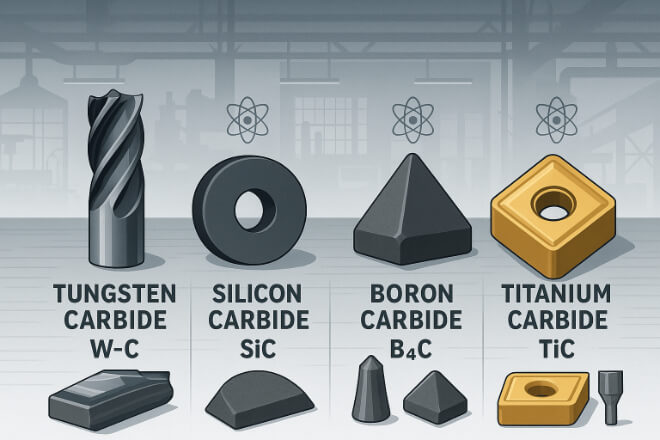

了解切削刀具中不同类型的碳化物

在机械加工中,选择合适的切削刀具会对加工结果产生重大影响——而许多刀具的核心材料是硬质合金。但并非所有硬质合金都一样。硬质合金有不同的类型和等级,每种类型和等级都针对特定的应用而设计。如果您是机械加工行业的决策者,了解 […]

在不锈钢上使用碳化钨切削刀具的最佳实践

不锈钢是一种坚韧耐用的材料,常用于航空航天、汽车、医疗和食品加工等行业。然而,由于不锈钢的硬度、韧性以及在切削过程中容易加工硬化的特性,其加工难度颇高。这正是碳化钨刀具大显身手的地方。碳化钨刀具以其[…]而闻名。

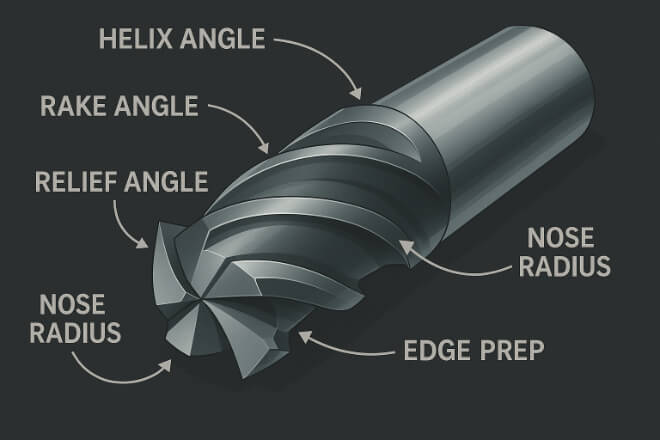

不同碳化钨切削刀具几何形状的比较

碳化钨刀具以其强度高、寿命长和加工硬质材料的能力而闻名。但一个经常被忽视的因素是刀具的几何形状——刀具切削刃的形状和角度。选择合适的几何形状可以显著提高加工速度、表面光洁度、切屑控制和刀具磨损。[…]

什么是碳化钨球?新手完全指南

碳化钨球是由一种名为碳化钨的超硬材料制成的小型球形部件。这些球因其优异的硬度、耐磨性和强度而被广泛应用于许多行业。如果您是碳化钨球领域的新手,本指南将帮助您了解它们是什么、它们是如何制造的,以及[…]

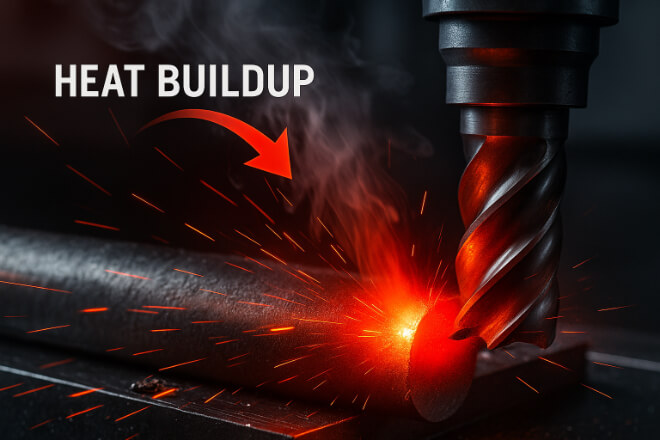

冷却液和润滑对碳化钨切削刀具的影响

在高速加工和精密制造领域,碳化钨切削刀具是实现精准高效加工的关键。这些刀具以其卓越的硬度和耐磨性而闻名。但即使是最好的刀具也需要一些辅助才能达到最佳性能——这时冷却液和润滑剂就派上用场了。使用 […]

碳化钨切削刀具可以回收吗?

在当今的制造业中,可持续发展不仅仅是一种趋势,更是一份责任。许多企业忽视的一个重要领域是切削刀具的回收利用,尤其是碳化钨刀具。如果您正在经营机械加工业务,您可能想知道:碳化钨切削刀具可以回收利用吗?简而言之,答案是肯定的,而且其益处深远 […]

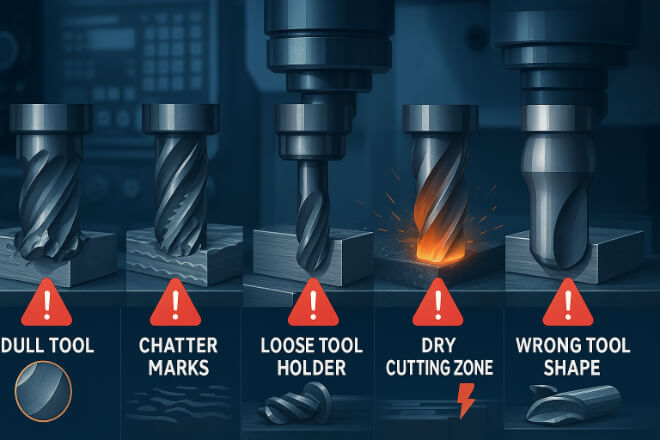

解决碳化钨切削刀具表面光洁度差的问题

在机械加工中,干净光滑的表面光洁度至关重要。它能够提升精度、节省后处理时间,并提升零件的整体质量。然而,即使使用高性能碳化钨刀具,表面光洁度差也是一个常见问题。本文将帮助您了解导致表面光洁度差的原因,以及如何识别其根源[…]

越南六大碳化钨工具制造商

越南制造业正在快速发展,硬质合金刀具行业也不例外。越来越多的工厂、机械加工公司,甚至跨国公司都将目光投向越南本土的硬质合金刀具供应商。那么问题来了:在众多选择中,哪些制造商真正值得信赖?在本文中,我们整理了一份 […]