用于泵、阀门和密封件磨损保护的碳化钨

在石油天然气、化学加工、采矿和发电等行业中,泵、阀门和密封件都面临着极端条件。它们通常在高压、磨蚀性颗粒和腐蚀性流体中运行。这种持续暴露会导致快速磨损和代价高昂的停机。碳化钨是全球信赖的解决方案之一。它以其硬度、耐磨性和[…] 而闻名。

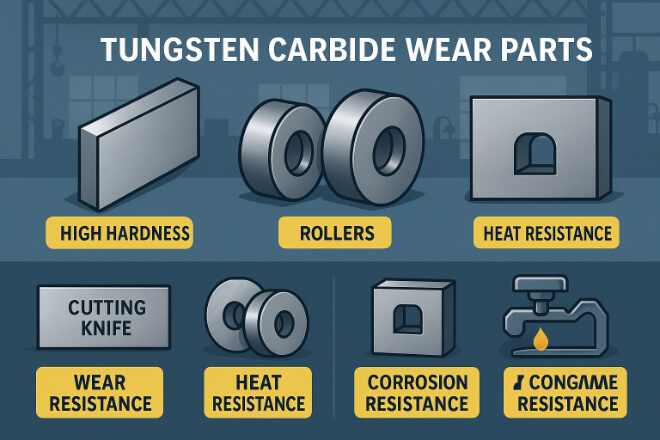

用于木工和切割应用的硬质合金耐磨部件

在木工和切割行业,效率、精度和耐用性是保持竞争力的关键。硬质合金耐磨部件已成为需要高性能工具的公司的首选。这些部件由碳化钨或其他硬质合金材料制成,耐磨、保持锋利更长时间,即使在高强度使用下也能保持良好的性能。这使得它们成为必不可少的[…]

碳化钨在造纸、纺织和包装机械中的应用

在当今的制造业中,造纸、纺织和包装行业的企业面临着激烈的竞争。他们需要能够长时间运行、生产高质量产品并保持低成本的机器。最大的挑战之一是处理机器零件的磨损。碳化钨耐磨件在这方面发挥着关键作用[…]

硬质合金耐磨零件在金属成型和冲压中的应用

在金属成型和冲压领域,设备的性能被推向极限。高压、重复运动和持续摩擦会迅速磨损普通刀具材料。正因如此,硬质合金耐磨件已成为众多制造企业值得信赖的选择。硬质合金零件以其硬度、耐磨性和长使用寿命而闻名,[…]

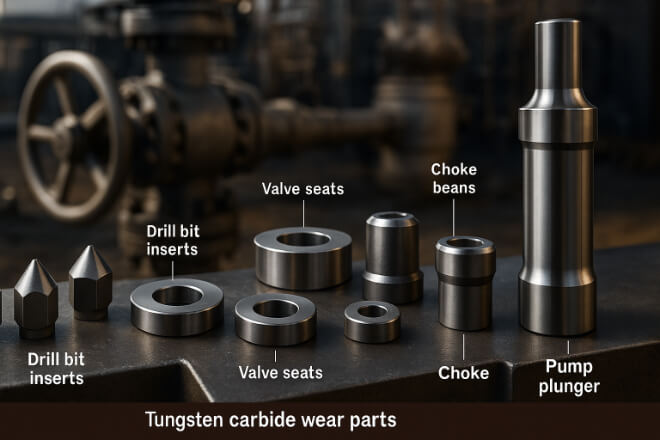

石油和天然气行业如何使用碳化钨耐磨部件

碳化钨耐磨部件在石油和天然气领域至关重要。它们能够确保钻机、泵、阀门和加工设备在极端条件下运行更长时间。对于该行业的决策者来说,了解这些部件的使用方式和原因有助于选择合适的供应商,提高设备性能,并降低维护成本。本文 […]

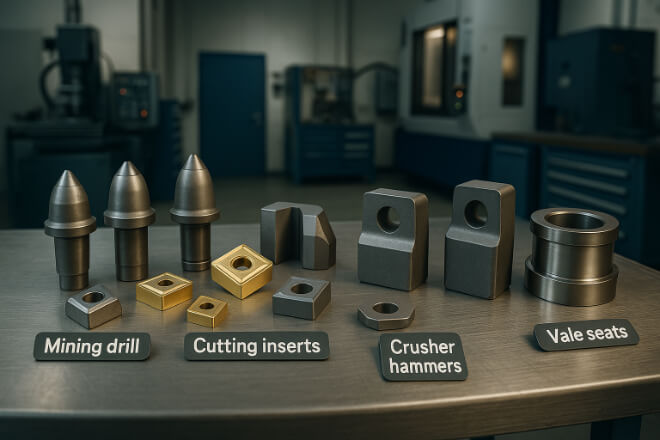

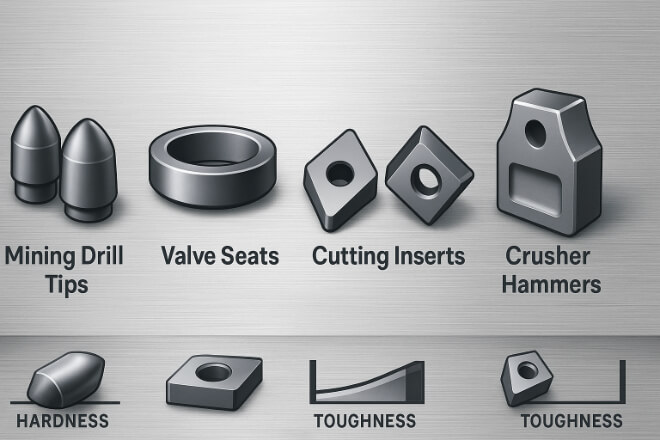

采矿业中的碳化钨耐磨件

采矿业是世界上最具挑战性的行业之一。设备每天都在高压、高温和磨蚀性条件下工作,承受着巨大的压力和压力,其性能也达到了极限。在这样的环境下,工具故障会导致代价高昂的停机和生产力下降。因此,碳化钨耐磨件至关重要。碳化钨是一种[…]

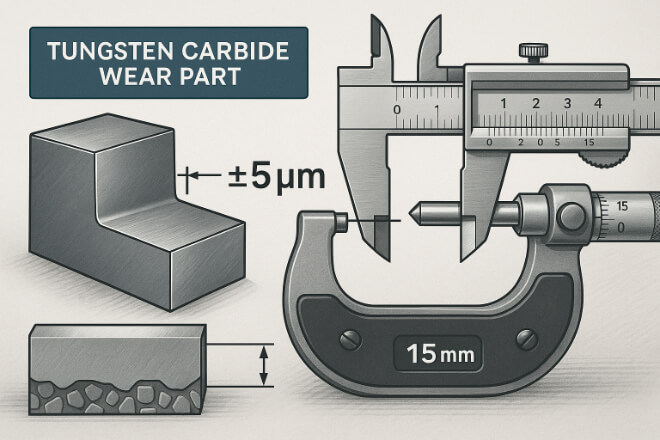

硬质合金磨损零件制造中的精密公差

在现代制造业中,精密公差不仅仅是一个技术细节,更是一项商业优势。在使用硬质合金耐磨零件的行业中,即使是最小的尺寸误差也可能导致更快的磨损、更长的停机时间和更高的成本。无论您生产的是采矿、石油天然气、汽车还是航空航天工具,满足严格的公差要求都能确保[…]

定制碳化钨耐磨件:设计技巧和标准

在采矿、石油天然气、建筑和制造等行业中,碳化钨耐磨件对于确保设备高效运行至关重要。这些部件承受着极端压力、高温和持续摩擦。虽然市面上有标准件,但许多公司需要定制设计以满足独特的运营需求。定制耐磨件可以帮助企业提高性能,降低[…]

烧结、研磨和涂层:耐磨部件的生产过程

磨损部件在采矿、石油天然气、金属加工和建筑等行业中至关重要。它们承受着极热、高压和持续摩擦的考验。为了在这些严苛的条件下生存,制造商采用烧结、研磨和涂层等先进工艺来生产兼具强度、韧性和耐久性的部件。本文将逐一介绍这些工艺 […]

碳化钨耐磨件是如何制造的

碳化钨耐磨件在采矿、石油天然气、金属切削和建筑等行业中至关重要。这些零件因其硬度、耐磨性和在极端工作条件下的长寿命而被广泛选用。对于决策者来说,了解碳化钨耐磨件的生产工艺有助于更好地选择供应商、质量控制和成本。这 […]