Carbide parts are widely used in industries such as 矿业, 石油和天然气, 汽车, 航天, 金工, and manufacturing. Their main value comes from 耐磨性, 硬度, and long service life.

However, not all carbide parts are made with the same quality. For companies that depend on carbide tools and wear parts, ensuring that these products meet ISO certification and testing standards is critical.

This article explains how ISO certification works, why wear resistance testing is important, and what steps decision-makers should take to verify that their carbide suppliers deliver products that are both authentic and reliable.

Why ISO Certification Matters for Carbide Parts

ISO (International Organization for Standardization) creates global standards to ensure quality, safety, and consistency. For carbide parts, ISO certification shows that the manufacturer:

Follows strict quality management systems (ISO 9001).

Uses proper inspection methods and calibrated equipment.

Provides traceability for raw materials and finished parts.

For decision-makers, working with an ISO-certified supplier reduces the risk of receiving low-quality or fake carbide parts.

It also helps meet regulatory or industry-specific requirements in markets like oil and gas, aerospace, and automotive.

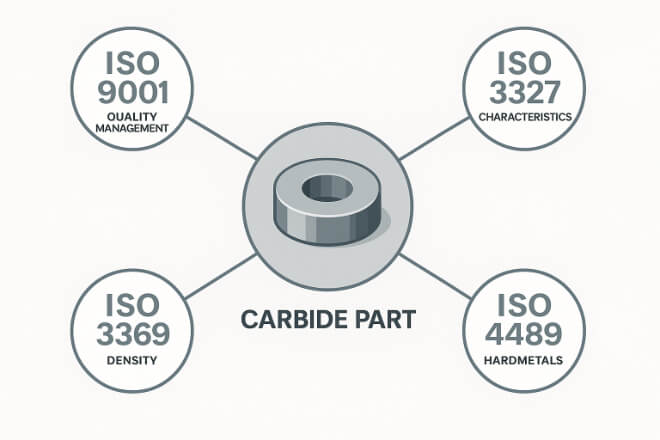

Common ISO Standards for Carbide Products

Several ISO standards are directly linked to tungsten carbide parts. The most relevant include:

ISO 9001 – Quality Management Systems

Ensures manufacturers follow structured processes for production, inspection, and customer service.

ISO 45001 – Health and Safety

Confirms safe workplace practices during carbide production, important due to cobalt handling.

ISO 14001 – Environmental Management

Shows commitment to sustainable manufacturing and waste reduction.

ISO 3327 – Hardness Test of Cemented Carbides

Defines how to measure the hardness of carbide using Rockwell or Vickers methods.

ISO 3369 – 密度 Determination of Hardmetals

Sets the method for testing density and 孔隙度 水平。

ISO 3738 – 断裂韧性 and Crack Resistance

Defines testing to evaluate 韧性 of cemented carbides.

ISO 4499 – Metallographic Determination of Grain Size

Provides guidance for checking microstructure and WC grain distribution.

These standards help ensure that carbide parts have consistent 耐磨性 and mechanical performance.

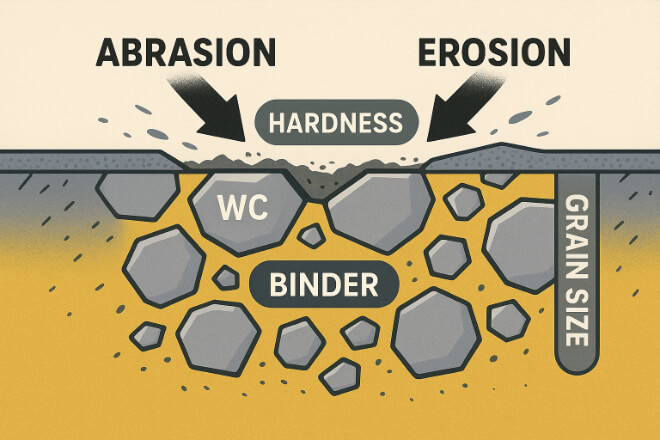

Understanding Wear Resistance in Carbide Parts

Wear resistance means how well carbide parts can withstand friction, abrasion, erosion, and contact stress during operation. This is the most important property because it directly impacts:

Tool life and replacement cost

Production efficiency and downtime

Machine protection and safety

Product reliability in critical applications

Carbide wear resistance is influenced by:

How Wear Resistance Is Tested

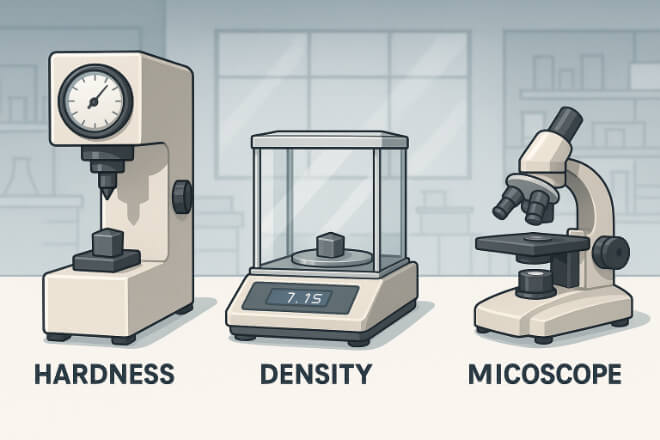

ISO standards guide different testing methods for carbide wear resistance. The most common include:

1). Hardness Testing (ISO 3327)

Rockwell A (HRA) and Vickers hardness tests measure carbide hardness.

Typical carbide parts range from HRA 89.5 to 92.5.

Higher hardness usually means higher 耐磨性。

2). 密度 和 孔隙率 Testing (ISO 3369)

Density indicates material compactness.

Standard carbide density is 14.5 – 15.0 g/cm³.

High porosity reduces wear resistance and strength.

3). 断裂韧性 Testing (ISO 3738)

Measures crack resistance.

Ensures carbide parts can survive impact and pressure without failure.

4). Abrasion and Erosion Testing

Sliding wear tests simulate friction against metals.

Erosion tests use abrasive particles or fluids.

Results help compare different carbide grades.

5). Metallographic Analysis (ISO 4499)

Microscopic analysis of grain structure.

Confirms uniform WC distribution and binder phase quality.

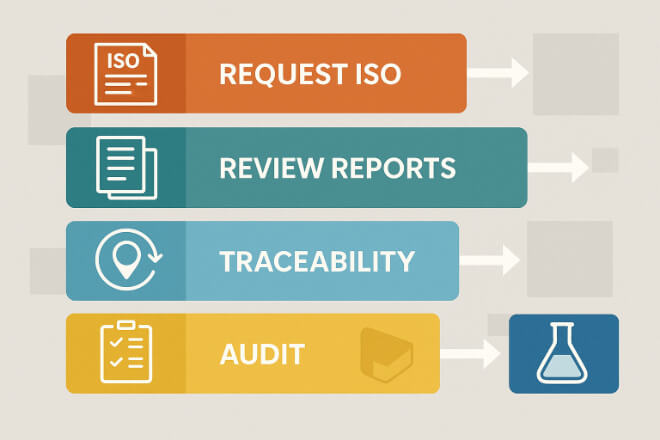

The Role of Certification in Supplier Evaluation

For decision-makers, ISO certification and testing are important tools for supplier selection. When evaluating a carbide supplier:

Ask for ISO certificates (9001, 14001, 45001).

Check if they follow regular audits and quality inspections.

Confirm traceability from raw powder to finished parts.

A supplier that cannot provide ISO documents and test results should be treated as a risk.

Benefits of Choosing ISO-Certified Carbide Parts

Working with ISO-certified suppliers gives many benefits:

Consistent Quality – Each batch meets the same standards.

Improved Reliability – Tools last longer and perform better.

Reduced Downtime – Less tool failure and fewer machine stops.

Lower Costs – Longer tool life reduces replacement needs.

Regulatory Compliance – Meets industry and government standards.

Customer Confidence – Easier to win contracts when using certified parts.

For industries like 石油和天然气, 航天, 和 汽车, ISO-certified carbide is not optional – it is often a requirement.

Case Example: Carbide Valve Seats in Oil & Gas

Valve seats in 石油和天然气 drilling equipment face extreme wear from sand, fluids, and high pressure.

An uncertified seat may erode quickly, causing leaks and downtime.

An ISO-tested carbide seat with 硬度 HRA 92 and 密度 14.9 g/cm³ may last five times longer.

This example shows how certification and testing can directly save costs and improve reliability in critical industries.

Steps for Decision-Makers to Ensure Authenticity

Request ISO Certificates – Verify they are valid and updated.

Review Test Reports – 硬度, 密度, 韧性, 和 wear testing.

Ask About Traceability – Raw powder, processing, and final inspection.

Visit or Audit Suppliers – If possible, review their process and lab.

Use Independent Testing – For large orders, confirm results with third-party labs.

结论

ISO certification and wear resistance testing are not just technical details – they are business-critical safeguards for decision-makers.

By choosing ISO-certified carbide suppliers and verifying wear resistance through proper testing, companies can protect their machines, reduce downtime, and ensure long-term reliability.

In industries where failure is not an option, ISO certification is proof of trust and performance.

如果您想了解任何公司的更多详细信息,请随时 联系我们。