In industries like power generation, 石油和天然气, chemical plants, and marine operations, 碳化钨密封环 are critical components.

They keep pumps, compressors, and valves running safely under high pressure, heat, and corrosive conditions. However, even the strongest material will wear out if not maintained properly.

For companies, extending the life of these seal rings means fewer shutdowns, lower costs, and more reliable equipment.

This article provides practical maintenance tips to help decision-makers ensure that tungsten carbide seal rings last as long as possible.

Why Maintenance Matters for Tungsten Carbide Seal Rings

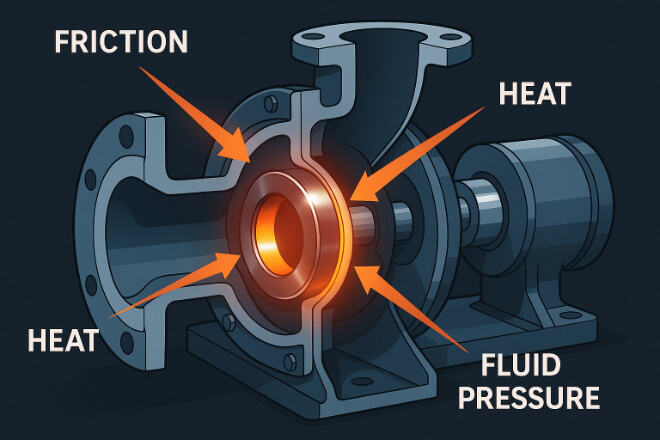

Although tungsten carbide is extremely hard and durable, seal rings still face challenges:

Friction from constant rotation or movement

Heat caused by pressure and mechanical load

Corrosive fluids such as seawater, oil, or chemicals

Shock from sudden changes in pressure

Without proper maintenance, even the best seal rings can fail early, leading to costly downtime and equipment damage.

Tip 1: Correct Installation

One of the most common reasons for seal ring failure is poor installation. To ensure long service life:

Follow the manufacturer’s installation guide carefully.

Avoid scratching or damaging the ring surface.

Ensure alignment of the shaft and housing.

Use the right tools and avoid forcing the seal into place.

Correct installation prevents uneven wear and ensures proper sealing.

Tip 2: Regular Inspection and Monitoring

Routine checks are vital for detecting early signs of wear. During inspection, look for:

Cracks or chips on the sealing surface

Uneven wear patterns

Corrosion marks

Leakage signs in pumps or valves

Early detection allows replacement before failure occurs, saving both time and cost.

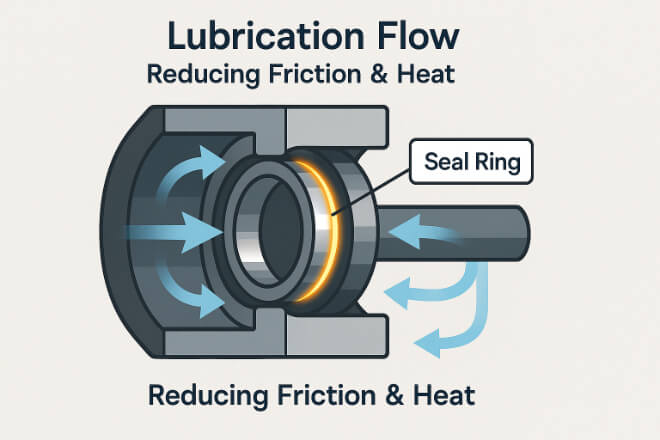

Tip 3: Use Proper Lubrication and Fluids

Lubrication reduces friction, heat, and surface damage. To improve performance:

Always use the recommended lubricants or process fluids.

Avoid contaminated fluids that carry abrasive particles.

Maintain correct fluid pressure and flow.

Lubrication not only protects the seal but also extends the life of the whole system.

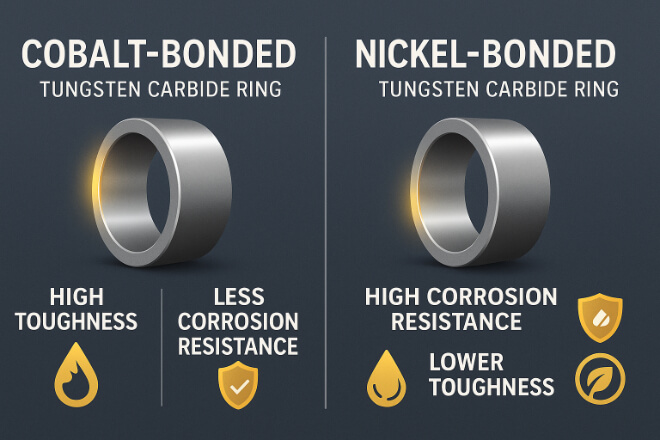

Tip 4: Choose the Right Seal Ring Grade

Not all tungsten carbide seal rings are the same. Two common binder options are:

Cobalt-bonded tungsten carbide – Offers higher 韧性 but less 耐腐蚀性.

Nickel-bonded tungsten carbide – Provides better corrosion resistance, suitable for seawater or chemical environments.

Selecting the right grade ensures the seal performs well under specific operating conditions.

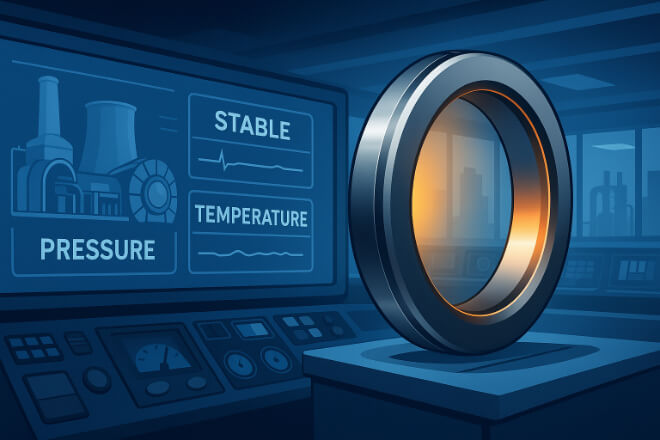

Tip 5: Control Operating Conditions

Seal rings last longer when machines are operated within designed limits. Companies should:

Avoid frequent starts and stops that create shock.

Monitor system pressure and temperature.

Prevent dry running, which causes rapid wear.

Stable operating conditions allow seal rings to perform at their best.

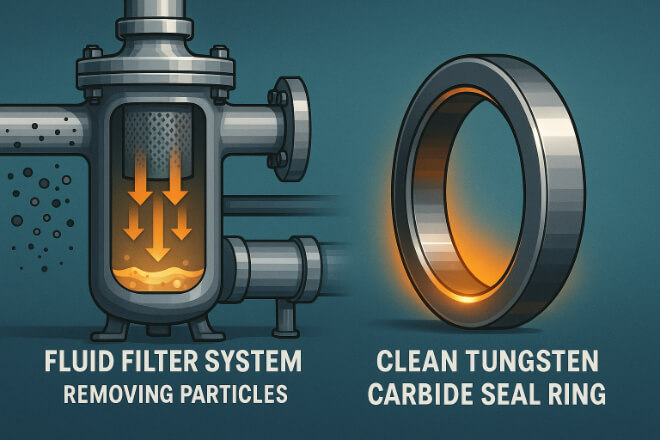

Tip 6: Keep Surfaces Clean

Contaminants such as dust, sand, or scale can scratch the seal surface. To prevent this:

Use filters to clean process fluids.

Flush systems regularly to remove debris.

Protect seals during shutdowns from dirt and corrosion.

A clean system means smoother operation and longer seal life.

Tip 7: Work with Certified Suppliers

Maintenance also depends on quality seals from trusted suppliers. Companies should always:

Buy from ISO-certified manufacturers.

Ensure materials meet required standards.

Ask for inspection and testing reports.

Using genuine tungsten carbide seal rings ensures durability and reduces maintenance headaches.

Long-Term Benefits of Proper Maintenance

For decision-makers, following maintenance best practices leads to:

Extended seal ring lifespan

Reduced downtime and repair costs

Higher equipment reliability

Better return on investment

Maintenance is not just a technical task—it is a business strategy that supports efficiency and safety.

结论

Tungsten carbide seal rings are strong, but their performance depends on how they are installed, operated, and maintained.

With the right practices—such as proper installation, regular inspection, correct lubrication, and choosing the right grade—companies can greatly extend their service life.

For industries where downtime is expensive and safety is critical, these maintenance tips provide both technical reliability and financial value.

如果您想了解任何公司的更多详细信息,请随时 联系我们。