密封圈是泵、压缩机、涡轮机和船舶系统中体积虽小但至关重要的部件。选择合适的密封圈材料,至关重要的是确保设备平稳运行,避免代价高昂的停机。

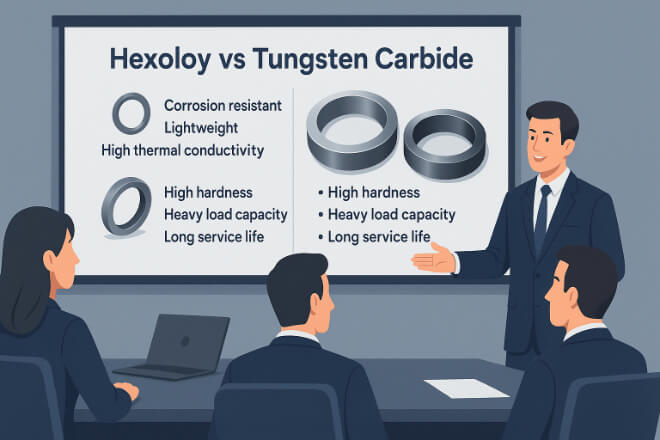

在众多选择中,Hexoloy(一种烧结碳化硅)和碳化钨是最常用的两种。

这两种材料都坚固耐用,适用于高要求行业。但它们并不相同。每种材料都有各自的优缺点,使其更适合某些应用。

本文比较了 Hexoloy 与 碳化钨密封环,帮助决策者为他们的系统选择正确的选项。

Hexoloy密封圈的强度

优越的 耐腐蚀

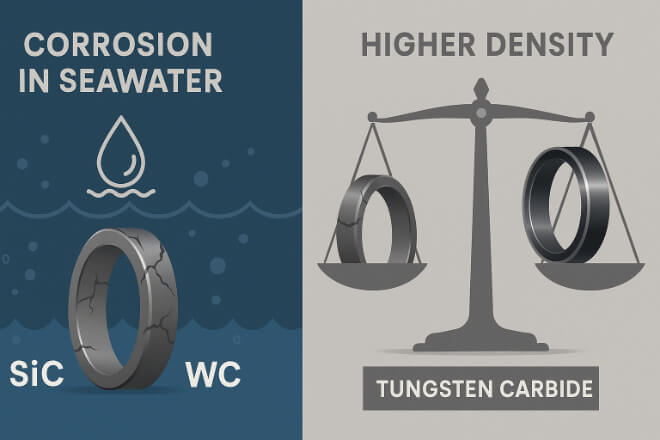

Hexoloy 比碳化钨更耐酸、碱和海水。这使其成为腐蚀性化学环境的最佳选择。

轻质材料

其低密度减轻了设备重量,从而可以提高泵和船舶系统的能源效率。

热导率

Hexoloy 均匀散热,避免热点并提高高温下的稳定性。

化学相容性

它在可能腐蚀金属粘合剂的腐蚀性流体环境中表现良好。

碳化钨密封环的优势

1). 更高 韧性

碳化钨比Hexoloy更不易碎。它能更好地承受机械冲击、振动和突然的压力变化。

2). 重载能力

它的抗压强度使其能够承受非常高的负载而不会破裂,从而使其在涡轮机和压缩机中更加可靠。

3). 使用寿命长

由于其耐磨性,碳化钨在泥浆泵等磨蚀条件下的使用寿命更长。

4). 可回收性

与许多陶瓷不同,碳化钨可以收集和回收,增加了可持续性优势。

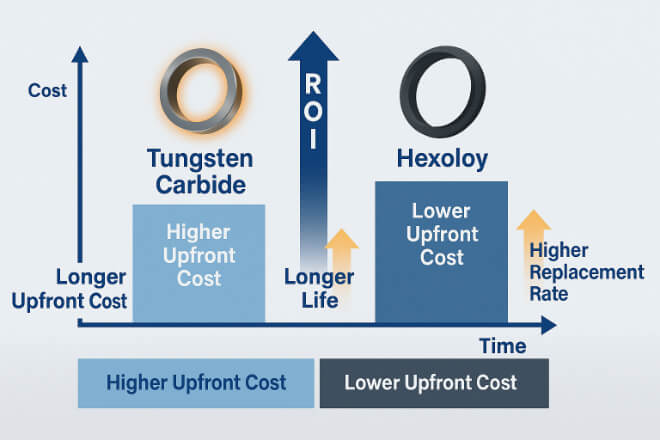

成本和生命周期考虑

在比较 Hexoloy 和碳化钨时,决策者应该考虑生命周期成本,而不仅仅是购买价格。

Hexoloy 的前期成本可能较低,并且具有理想的耐化学性,但在重载条件下更高的更换频率会增加长期成本。

碳化钨的初始成本较高,但在高压、高冲击系统中使用寿命更长,从而降低停机成本。

行业应用:何时选择

1). Hexoloy密封圈最适合:

含有腐蚀性流体的化工厂

腐蚀是主要风险的船用海水泵

密度至关重要的轻量级系统

2). 碳化钨密封环最适合用于:

发电涡轮机和压缩机

承受高负荷的石油和天然气泵

高应力船舶推进系统

停机成本高的应用

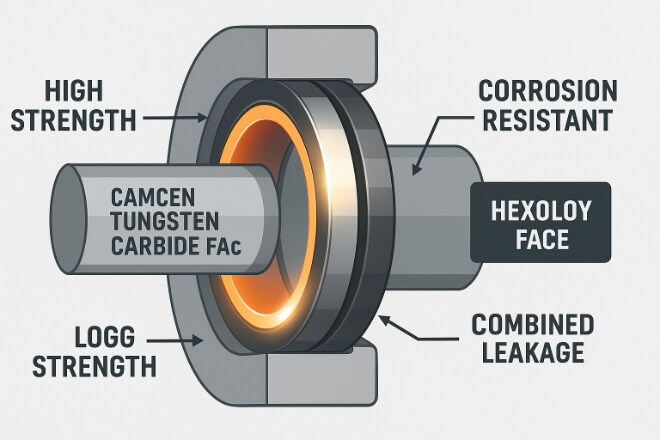

混合解决方案

一些公司使用两种不同的材料:一面由碳化钨制成,另一面由 Hexoloy 制成。

这使得系统兼具韧性和耐腐蚀性。混合密封面通常能实现性能和成本之间的最佳平衡。

决策者的关键要点

当耐腐蚀性、化学兼容性和轻量化设计是优先考虑因素时,请选择 Hexoloy。

当需要韧性、重载能力和长使用寿命时,请选择碳化钨。

考虑混合解决方案来结合两者的最佳特性。

正确的选择取决于您的具体操作环境、维护策略和长期成本目标。

结论

Hexoloy 和碳化钨密封环在现代密封解决方案中都发挥着重要作用。

Hexoloy 具有卓越的耐腐蚀性和热稳定性,而碳化钨在冲击和压力下具有无与伦比的韧性和耐用性。

对于决策者来说,最佳选择取决于系统的环境。

在许多情况下,仔细的生命周期成本分析会表明,碳化钨更适合重载使用,而Hexoloy则更适合富含化学物质的环境。在某些情况下,两者结合才是最有效的策略。

如果您想了解任何公司的更多详细信息,请随时 联系我们。