Pumps are critical components in industries like 石油和天然气, power generation, chemical processing, and marine operations.

A single leak can cause costly downtime, environmental risks, and safety hazards. To avoid these issues, mechanical seals must be durable and reliable.

碳化钨密封环 are one of the most trusted solutions for leak-free pump operation. This article explains their properties, advantages, applications, and best practices for decision-makers.

Why Leak-Free Pump Operation Matters

Prevents fluid loss → Protects resources and reduces waste.

Maintains efficiency → Pumps perform better without pressure loss.

Reduces maintenance costs → Fewer failures mean fewer repairs.

Protects the environment → Prevents spills of hazardous materials.

Ensures safety → Avoids dangerous leaks near operators or equipment.

碳化钨密封环的性能

碳化钨是钨和碳的化合物,并与钴或镍结合。其特性包括:

极端 硬度 → 抵抗摩擦和颗粒磨损。

高抗压强度 → Handles heavy loads without cracking.

耐腐蚀 → Works well with chemicals, seawater, and oils.

热稳定性 → Maintains sealing performance under high heat.

尺寸稳定性 → Ensures precise sealing over long periods.

These properties help pumps stay leak-free under tough conditions.

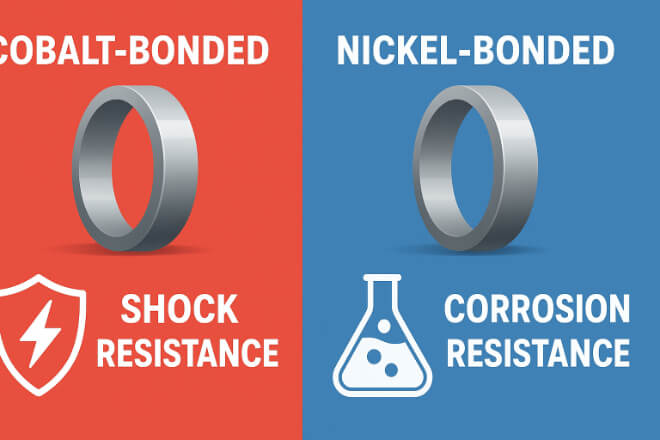

钴结合碳化钨与镍结合碳化钨

1). 钴结碳化钨

Best for vibration-heavy or high-shock pumps.

Common in oilfield and mining operations.

2). 镍结碳化钨

优越的 耐腐蚀。

Ideal for chemical plants, marine pumps, and wastewater systems.

Choosing the right binder ensures long service life and reliable sealing.

优于其他密封材料

| 特征 | 碳化钨 | 陶瓷制品 | 钢 |

|---|---|---|---|

| 耐磨性 | 非常适合磨料 | 缓和 | 贫穷的 |

| 耐腐蚀 | 高(镍等级) | 非常好 | 低的 |

| 韧性 | 高,抗冲击 | 低、脆 | 缓和 |

| Thermal Performance | Excellent at high heat | 好的 | 缓和 |

| 使用寿命 | 持久 | 缓和 | 短的 |

Applications in Pump Systems

碳化钨密封环用于:

Chemical pumps → Handle aggressive fluids safely.

船用泵 → Resist seawater corrosion.

Oil and gas pumps → Prevent leaks under pressure.

Wastewater pumps → Manage abrasive and corrosive fluids.

发电厂冷却泵 → Maintain leak-free operation for critical systems.

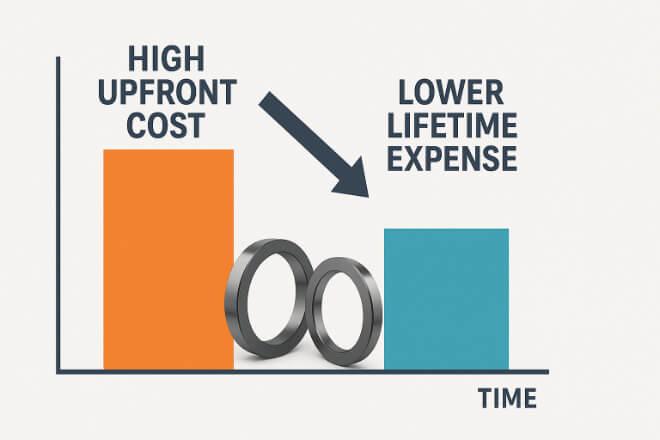

成本与长期价值

While tungsten carbide rings cost more upfront:

更少的替换 → 降低备件成本。

减少停机时间 → Increases production efficiency.

Extended equipment life → Protects pump components.

更好的投资回报率 → Long-term savings outweigh initial price.

环境和安全效益

防止泄漏 → Avoids contamination and environmental damage.

可回收材料 → Supports sustainable practices.

Energy efficiency → Preventing leaks reduces wasted energy.

Best Practices for Leak-Free Performance

Select the right binder → Match to chemical and mechanical conditions.

Ensure proper installation → 避免划痕或错位。

使用适当的润滑剂 → Reduces friction and heat.

定期检查 → Catch wear early before leaks start.

与可靠的供应商合作 → 确保材料质量和正确的规格。

决策者的关键要点

碳化钨密封环 ensure leak-free pump operation under tough conditions.

Choosing the correct grade (nickel or cobalt) is critical for performance.

Their durability, recyclability, and efficiency lower costs and environmental risks.

Investing in tungsten carbide protects pumps and improves ROI.

结论

For pumps in chemical plants, power stations, marine systems, and oilfields, tungsten carbide seal rings are a proven choice for preventing leaks.

Their hardness, corrosion resistance, and strength deliver long-term performance, reduced downtime, and environmental protection.

For decision-makers, selecting tungsten carbide is a strategic investment in safety, sustainability, and cost efficiency.

如果您想了解任何公司的更多详细信息,请随时 联系我们。