Liquefied natural gas (LNG), cryogenic fluids, and other low-temperature applications are critical in energy, chemical, and 航天 industries.

These systems operate at extreme cold, where ordinary seal materials can become brittle, shrink, or crack. Seal failure under such conditions can stop operations, cause leaks, or create dangerous situations.

硬质合金密封环 are engineered to handle these demanding duties. With their 硬度, 韧性, and resistance to temperature changes, they ensure pumps, compressors, and 阀门 remain reliable.

For decision-makers, carbide seals mean fewer breakdowns, safer operations, and long-term cost savings.

Challenges in LNG and Cryogenic Applications

Extreme cold makes many metals and polymers brittle.

Rapid temperature changes cause thermal shock, stressing seals.

High pressures in LNG transfer systems demand strong sealing surfaces.

Chemical exposure from cryogenic fluids can corrode or weaken some materials.

Standard stainless steel or ceramic seals often fail in these conditions.

Carbide seal rings are designed for performance in harsh low-temperature environments.

Why Carbide Seal Rings Excel in Low-Temperature Duties

硬度 和 耐磨性: Carbide resists scratches and abrasion from particles in cryogenic fluids.

Thermal Stability: Carbide maintains sealing integrity even at -196°C (-321°F) for LNG applications.

Strength and Shock Resistance: Cobalt-bonded carbide absorbs thermal shock and mechanical vibration without cracking.

耐腐蚀: Nickel-bonded carbide resists chemical attack from cryogenic liquids or trace contaminants.

Long Service Life: Reduced wear and corrosion lower maintenance frequency and improve uptime.

Applications in LNG and Cryogenic Systems

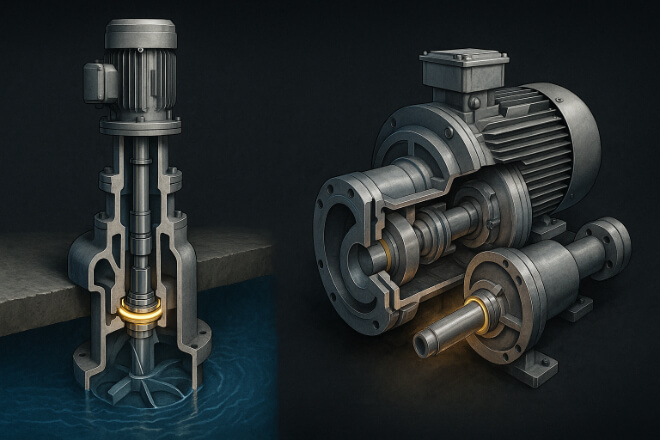

1). LNG Transfer Pumps

Carbide seals prevent leaks in pumps moving super-cooled natural gas between storage and ships.

2). Cryogenic Compressors

High-speed compressors for gases like oxygen, nitrogen, or hydrogen depend on carbide rings for stability.

3). Valves and Control Systems

Carbide seals ensure reliable closure in valves used in cold pipelines and storage systems.

4). 航天 and Research

Liquid hydrogen and oxygen systems in rockets and laboratories use carbide seals for safety and precision.

对工业运营的益处

| 益处 | Impact |

|---|---|

| Durability in Cold | Resists brittleness and cracking at extreme low temperatures. |

| Leak Prevention | Keeps LNG and cryogenic fluids securely contained. |

| Lower Maintenance | Longer seal life reduces replacement and repair costs. |

| Operational Reliability | Improves uptime for LNG plants, pipelines, and aerospace systems. |

| Safety and Compliance | Prevents hazardous leaks, supporting industry safety standards. |

案例研究

LNG Terminal Pump Upgrade

A coastal LNG terminal replaced steel seals with nickel-bonded carbide rings.

Result: improved reliability during rapid cool-down cycles and fewer emergency maintenance calls.

Aerospace Cryogenic System

A rocket manufacturer adopted cobalt-bonded carbide seals in liquid oxygen pumps.

Result: reduced thermal shock failures and improved launch reliability.

How to Choose the Right Carbide Seal Ring

1). 粘合剂类型

Nickel-bonded carbide for corrosive or chemically active cryogenic fluids.

Cobalt-bonded carbide for systems prone to vibration or sudden temperature changes.

2). 表面处理

Polished carbide minimizes friction and wear in high-speed pumps or compressors.

3). 操作条件

Consider temperature range, pressure levels, and fluid composition.

4). 供应商专业知识

Work with ISO-certified suppliers experienced in LNG and cryogenic duties.

Maintenance and Replacement Best Practices

Inspect seals during scheduled outages or refits.

Replace seals proactively to prevent leaks or equipment failure.

Stock spare carbide seals for critical LNG transfer pumps and cryogenic compressors.

Recycle worn carbide components to reduce environmental impact and costs.

成本和投资回报率考虑因素

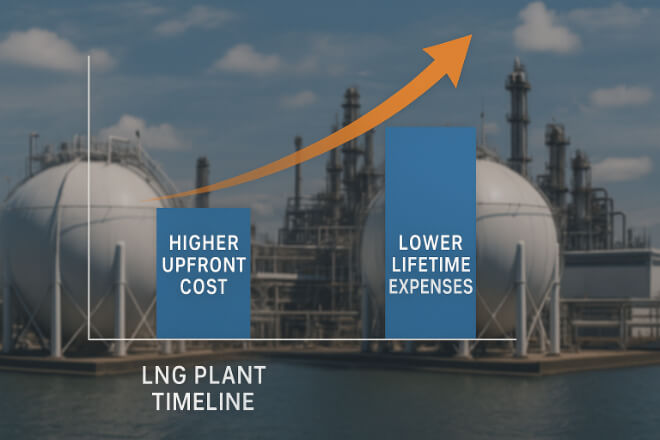

Upfront Cost: Carbide seals are more expensive than standard alternatives.

Savings: Longer service life and fewer leaks reduce maintenance and downtime.

ROI: Improved safety, compliance, and reliability offset the higher purchase price.

环境和安全优势

LNG and cryogenic leaks can be hazardous and environmentally damaging. 硬质合金密封环 reduce leak risks, protect workers, and ensure compliance with strict safety regulations.

结论

Carbide seal rings are essential for LNG, cryogenic, and other low-temperature duties.

Their durability, corrosion resistance, and thermal stability make them the best option for pumps, compressors, and valves operating under extreme cold.

For decision-makers, carbide seals offer improved safety, fewer breakdowns, and lower lifetime costs—key benefits in competitive and high-risk industries.

如果您想了解任何公司的更多详细信息,请随时 联系我们。