In today’s global manufacturing market, sourcing tungsten carbide bushings is not just about finding a supplier — it’s about finding the right partner.

Tungsten carbide bushings are critical components in pumps, compressors, turbines, and drilling tools. Their reliability depends heavily on material purity, manufacturing precision, and quality control.

As industries become more international, global sourcing allows companies to access better pricing, advanced technology, and specialized expertise.

However, choosing the right tungsten carbide bushing manufacturer requires careful evaluation of capability, quality, and certification.

This article serves as a comprehensive sourcing guide, helping procurement managers and engineers identify top global manufacturers, key selection factors, and regional strengths.

What Makes a Good Tungsten Carbide Bushing Manufacturer

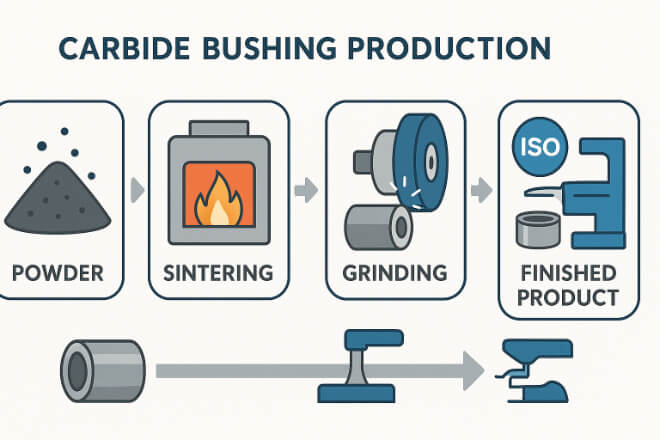

Not all carbide suppliers are the same. A strong manufacturer combines material science, precision processing, and quality assurance.

Key Qualities to Look For:

In-house powder metallurgy (not just machining)

ISO 9001 or ISO 14001 certification

Automatic pressing and sintering lines

Advanced CNC and centerless grinding machines

Material traceability and EN 10204 3.1 certificates

Customization options for different applications (石油和天然气, marine, mining, etc.)

These features ensure stable performance, long service life, and repeatable precision in every batch.

Regional Overview of Global Production

The tungsten carbide industry is distributed worldwide, but certain regions have specialized strengths.

| Region | 优势 | Key Advantages |

|---|---|---|

| China | Largest global producer of tungsten powder and carbide products | Competitive pricing, advanced sintering, broad size range |

| Germany | High-end engineering and precision finishing | Strict quality control, premium tools |

| USA | Specialized industrial-grade bushings for oil, aerospace, and energy | Strong R&D, short lead times |

| Japan | Micrograin carbide and surface finish precision | Excellent consistency, ideal for high-precision applications |

| India | Fast-growing market with strong OEM partnerships | Flexible production and cost advantage |

Each region provides unique value — from low-cost bulk production to micro-precision finishing.

Top Tungsten Carbide Bushing Manufacturers Worldwide

Below are examples of reputable global suppliers known for quality, capacity, and reliability.

1). CERATIZIT (Europe)

Headquartered in Luxembourg, CERATIZIT is one of the world’s most respected carbide producers.

They specialize in powder-to-product manufacturing, offering custom tungsten carbide bushings with strict metallurgical control.

ISO 9001, ISO 45001 certified

Extensive R&D in micrograin carbide

Strong supply network across Europe and Asia

2). Kennametal (USA)

A leading American manufacturer serving 石油和天然气, mining, and 航天. Known for innovation and robust 磨损件.

Global supply chain and material traceability

Advanced coating and finishing technologies

Strong technical documentation

3). Zhuzhou Cemented Carbide Group (China)

As one of the largest tungsten carbide producers in the world, Zhuzhou Group provides bushings, seals, and tools for OEM and industrial clients.

Vertically integrated supply chain

Cost-effective production

Available EN 10204 3.1 certificates

4). Sumitomo Electric Hardmetal (Japan)

Recognized for micrograin technology and precision bushings for pumps, compressors, and semiconductor equipment.

Tight tolerance control

Stable surface finish performance

Premium quality for high-end applications

5). Hyperion Materials & Technologies (Global)

Operating in over 20 countries, Hyperion focuses on engineered wear-resistant solutions.

Broad product portfolio

High-performance binder systems

Excellent global customer support

How to Evaluate a Potential Supplier

Choosing the right manufacturer requires more than comparing prices. Decision-makers should evaluate based on technical, logistical, and quality factors.

Key Evaluation Criteria:

Material Certification: Verify EN 10204 3.1 or ISO compliance.

Experience in Your Industry: Suppliers familiar with your environment (oil, marine, chemical) can recommend the right grade.

Machining Capability: Look for internal grinding, lapping, and coating capacity.

MOQ and Lead Time: Ensure flexibility for both small and bulk orders.

After-Sales Service: Technical support, traceability, and defect handling.

A strong supplier provides more than bushings — they deliver confidence and technical assurance.

Cost and Quality Balance in Global Sourcing

Global sourcing can deliver big savings, but quality consistency must always come first.

The best strategy is “Total Value Sourcing” — balancing cost, quality, and reliability rather than choosing the lowest price.

| Region | Average Cost Level | Typical Quality Grade | 最适合 |

|---|---|---|---|

| China | 低至中等 | Industrial grade, OEM production | Mass production and cost savings |

| Germany | 高的 | Premium precision grade | High-end applications |

| India | Medium–Low | Good quality at flexible pricing | OEM partnerships |

| Japan | 高的 | Micrograin, high-precision quality | Critical tolerance applications |

An ideal sourcing plan may involve multi-region sourcing — combining low-cost bulk supply with premium-grade precision components from advanced markets.

How to Build Long-Term Partnerships

Building reliable supplier relationships is essential for consistent performance.

Here’s how leading companies achieve that:

Start with trial orders to evaluate quality and communication.

Share technical drawings and material expectations clearly.

Negotiate flexible MOQ and lead time agreements.

Request annual quality reports and certification renewal.

Develop dual-sourcing plans to reduce risk of disruption.

The best global partnerships are built on transparency, trust, and mutual benefit.

结论

Global sourcing of tungsten carbide bushings gives companies access to better materials, specialized skills, and cost advantages.

By carefully selecting manufacturers based on capability, certification, and regional expertise, decision-makers can ensure a secure and efficient supply chain.

Whether sourcing from China for large-scale production or Germany for precision finishing, the key is to align supplier strengths with your technical and operational needs.

如果您想了解任何公司的更多详细信息,请随时 联系我们。