Tungsten carbide bushings are integral components in various industrial applications, particularly where high 耐磨性, 韧性, and durability are required.

These bushings are often subjected to harsh conditions, such as high loads, high speeds, and extreme temperatures. To ensure optimal performance and longevity, proper alignment of the shaft and housing during installation is crucial.

Misalignment can lead to excessive wear, premature failure, and costly downtime.

This blog will discuss the importance of aligning the shaft and housing for tungsten carbide bushings, common alignment issues, and best practices for achieving a perfect fit.

Why Alignment Matters for Tungsten Carbide Bushings

Alignment between the shaft and housing is critical for the proper functioning of tungsten carbide bushings.

When installed correctly, the bushing acts as a wear-resistant barrier, ensuring that the shaft operates smoothly within the housing.

If the alignment is off, the bushing may experience uneven pressure, which can lead to premature failure.

1). Effects of Poor Alignment:

Increased Wear: Misalignment causes uneven pressure distribution across the bushing, leading to excessive wear in certain areas.

Overheating: Uneven pressure causes friction, which generates heat. Over time, this heat can degrade the bushing material.

Cracking or Chipping: If the bushing is misaligned, it may experience localized stress that could cause cracks or chips in the material.

Reduced Efficiency: Misalignment creates friction that hampers the smooth operation of machinery, leading to energy loss and reduced system efficiency.

2). How Alignment Affects Longevity:

Proper alignment ensures that the bushing functions as intended, minimizing wear, reducing heat generation, and enhancing the overall lifespan of the component.

Common Causes of Misalignment

There are several reasons why misalignment might occur during the installation of tungsten carbide bushings. Understanding these causes can help prevent alignment issues from arising.

1). Improper Installation

One of the most common causes of misalignment is improper installation. If the components are not aligned correctly during assembly, the bushing will not fit properly, leading to issues down the line.

Solution: Use precise installation tools, such as alignment jigs, to ensure accurate positioning of the bushing.

2). Wear and Tear Over Time

Over time, components like shafts and housings can wear down, causing slight shifts in alignment.

This is particularly true in high-load or high-speed applications, where friction can gradually alter the alignment.

Solution: Regular inspections and maintenance can help detect wear and misalignment before it becomes a problem.

3). Manufacturing Defects

In some cases, misalignment can occur due to manufacturing defects in the shaft or housing. Inaccurate machining can result in components that do not fit together properly.

Solution: Ensure that all components are manufactured to precise tolerances, and inspect them thoroughly before installation.

How to Achieve Proper Alignment

Achieving proper alignment between the shaft and housing is essential for the optimal performance of tungsten carbide bushings. Here are some best practices to ensure correct alignment during installation.

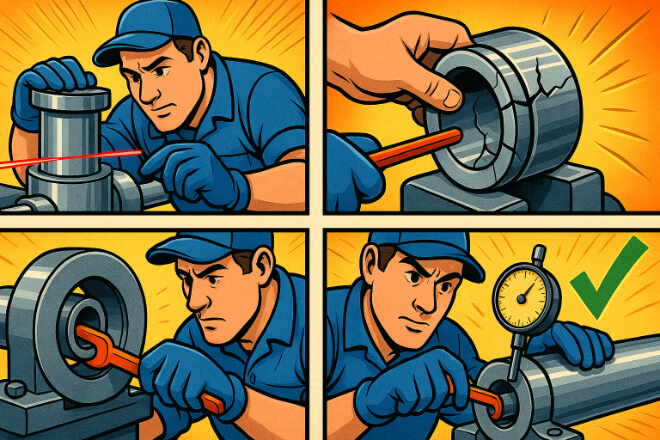

1). Use Precision Alignment Tools

Using precision alignment tools is the most effective way to ensure that the shaft and housing are aligned properly.

These tools provide real-time measurements and adjustments, allowing you to fine-tune the alignment before the installation is complete.

Laser Alignment Systems: These systems use lasers to measure and adjust the alignment of the shaft and housing. They are highly accurate and provide instant feedback, which is crucial for achieving precise alignment.

Dial Indicators: A dial indicator measures any displacement between the shaft and housing. It can be used to detect even the slightest misalignment.

2). Verify the Shaft and Housing Dimensions

Before installing the bushing, check the dimensions of both the shaft and housing to ensure they match the specifications. Any variations in size can result in improper fit and misalignment.

Tools to Use: Micrometers, calipers, and bore gauges are essential tools to measure the shaft and housing diameters. These tools help ensure that the components are within the required tolerances for proper fit.

3). Gradual Installation Process

When press-fitting a tungsten carbide bushing, applying pressure gradually is essential to avoid misalignment.

Using a press machine with controlled pressure ensures that the bushing is evenly fitted into place without any sudden shifts that could cause misalignment.

Tip: Apply pressure slowly while continuously checking alignment to ensure that the bushing is fitting correctly.

4). Use Support Jigs and Fixtures

Support jigs and fixtures can help hold the shaft and housing in place during installation, preventing them from shifting during the press-fit process.

This ensures that the components stay aligned as the bushing is installed.

Tip: Use adjustable fixtures that can be fine-tuned to ensure proper alignment throughout the installation.

Maintenance to Prevent Misalignment

Misalignment may not only occur during installation but can also develop over time due to wear, vibrations, and changes in operational conditions.

Regular maintenance is crucial to preventing misalignment from affecting the bushing system.

1). Regular Inspections

Conducting regular inspections of the shaft and housing is essential to identify any signs of misalignment or wear.

Look for signs such as increased vibration, unusual noise, or overheating, as these can indicate that the bushing system is misaligned.

How to Inspect: Use alignment tools to check for misalignment periodically, especially in high-load or high-speed applications.

2). Monitoring Vibration and Noise

Excessive vibration or noise is often a sign of misalignment in the bushing system. These symptoms should be addressed immediately to prevent further damage.

How to Monitor: Install vibration sensors or use manual monitoring methods to detect abnormal vibrations. Regular checks can prevent misalignment from escalating into more serious issues.

3). Lubrication and Cooling

Lubrication and cooling systems are essential for maintaining the proper alignment of the bushing. Insufficient lubrication can cause friction, increasing the risk of misalignment due to heat and wear.

Tip: Ensure that the bushing and surrounding components are adequately lubricated to reduce friction and prevent misalignment due to excessive wear.

Common Causes of Misalignment and Solutions

| 工具类型 | 描述 | 好处 |

|---|---|---|

| Laser Alignment Tools | Laser-based systems for real-time alignment measurements | High accuracy, quick feedback, minimal human error |

| Dial Indicators | Mechanical devices for measuring misalignment | Precise measurement, easy to use, cost-effective |

| Bore Gauges | Tools for checking the diameter of the housing bore | Ensures correct housing dimensions for proper fit |

结论

Proper alignment of the shaft and housing is crucial for the effective performance and longevity of tungsten carbide bushings. Misalignment leads to excessive wear, overheating, and premature failure.

By following best practices for installation, regular inspections, and using precision tools, companies can ensure that their bushing systems remain properly aligned, efficient, and durable.

Regular maintenance, including checking for misalignment and ensuring proper lubrication, is essential for preventing alignment-related issues.

如果您想了解任何公司的更多详细信息,请随时 联系我们。