Tungsten carbide bushings are crucial components used in a wide variety of industrial applications due to their exceptional 硬度, 耐磨性和耐用性。

However, the properties of tungsten carbide, especially its hardness and wear resistance, are significantly influenced by the grain size of the tungsten carbide particles.

Optimizing grain size during production is essential for improving the performance and lifespan of tungsten carbide bushings.

This article will explore how grain size optimization affects the performance of tungsten carbide bushings, the process of achieving optimal grain size, and why it is a key factor in ensuring high-quality bushing production.

Understanding the Role of Grain Size in Tungsten Carbide

Tungsten carbide is a composite material made by bonding tungsten carbide grains with a binder material, typically cobalt or nickel.

The grain size of the tungsten carbide particles plays a vital role in determining the material’s overall properties, including its hardness, toughness, and wear resistance.

Fine Grains:

Smaller tungsten carbide grains lead to higher 硬度 and better 耐磨性 because they create a more densely packed structure.

However, fine grains tend to be brittle, making the material more prone to cracking under high mechanical stress.

Coarse Grains:

Larger grains provide greater toughness and resilience but may sacrifice wear resistance.

Coarse-grain tungsten carbide is often used in applications requiring strength and shock resistance rather than wear resistance.

1). Why is Grain Size Important?

硬度: Fine grains contribute to increased hardness.

耐磨性: Smaller grains lead to better wear performance, making them ideal for high-friction environments.

韧性: Larger grains offer better resistance to impact and shock.

By carefully controlling grain size, manufacturers can tailor the material’s properties to suit specific application requirements.

The Impact of Grain Size on Tungsten Carbide Bushing Performance

In bushing production, grain size optimization directly impacts the performance of the final product.

When the grain size is optimized correctly, it leads to bushings that are both durable and tough enough to handle harsh industrial environments.

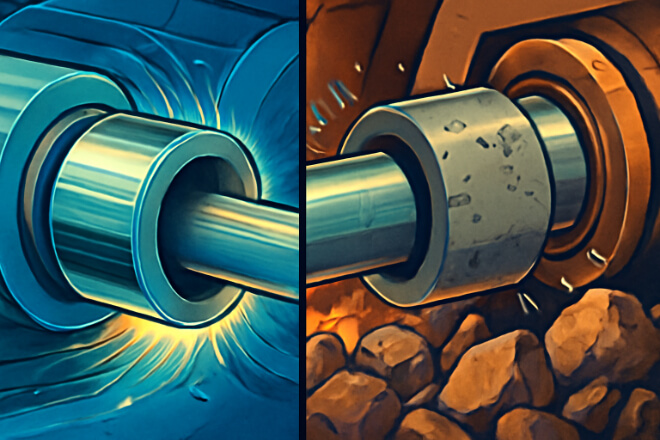

1). Fine-Grain Tungsten Carbide for 耐磨性

Fine-grain tungsten carbide is ideal for applications where wear resistance is critical, such as in pumps, valves, and other moving parts.

These bushings perform well in abrasive environments, such as those found in mining, drilling, or high-speed machinery, where the parts are subjected to constant friction.

1.1). Example Applications:

矿业 equipment

High-precision machining tools

Chemical pumps

1.2). Benefits of Fine-Grain Tungsten Carbide:

Superior wear resistance: Fine grains help prevent surface degradation and maintain the bushing’s integrity over time.

Longer lifespan: The finer the grain, the longer the bushing’s service life, reducing maintenance costs.

However, there’s a trade-off. Fine grains can make the bushing brittle, which means it might crack or break under shock loads or high-pressure conditions.

2). Coarse-Grain Tungsten Carbide for 韧性

Coarse-grain tungsten carbide is preferred when toughness and impact resistance are more important than wear resistance.

This material is often used in applications where the bushings will be exposed to high mechanical stress, such as in impact or shock environments.

2.1). Example Applications:

Mining machinery

High-load equipment

Industrial presses

2.2). Benefits of Coarse-Grain Tungsten Carbide:

High toughness: Larger grains offer better resistance to impact and shock, making them ideal for rugged applications.

Better resilience: Coarse grains help the bushing absorb shock loads without cracking.

However, coarse grains result in reduced wear resistance, meaning these bushings may not perform as well in abrasive environments compared to fine-grain bushings.

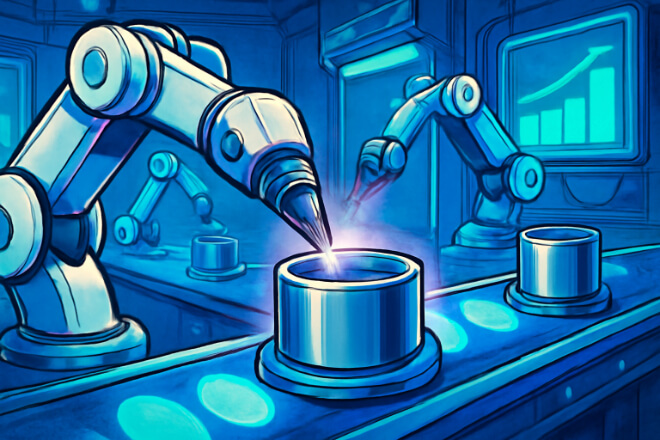

Achieving Optimal Grain Size in Tungsten Carbide Bushing Production

The key to producing high-quality tungsten carbide bushings lies in achieving the right grain size through controlled manufacturing processes.

The grain size can be adjusted during the sintering process, where tungsten carbide powder is heated to form a solid piece. The following factors influence grain size optimization:

1). Powder Composition

The type of 碳化钨粉 used, along with the binder (such as cobalt or nickel), plays a crucial role in determining the final grain size.

By using specialized powders and adjusting the ratio of binder material, manufacturers can control the grain size.

2). Sintering Temperature and Time

The sintering temperature and the duration for which the tungsten carbide is heated significantly impact the grain size.

Higher sintering temperatures generally promote larger grains, while lower temperatures help maintain finer grains.

Manufacturers carefully control these parameters to achieve the desired balance of 硬度, 耐磨性, 和 韧性.

3). 添加剂和涂料

Certain additives and surface coatings can be used during production to help refine the grain structure and improve the final performance of the bushings.

For example, using carbon as an additive can help control the grain growth during the sintering process.

Benefits of Grain Size Optimization in Tungsten Carbide Bushings

Optimizing grain size leads to the following benefits:

Enhanced Performance: Proper grain size ensures that the bushings meet specific requirements, whether for 耐磨性, 韧性, or impact resistance.

Improved Durability: Optimized grain size results in bushings that last longer and withstand harsh operating conditions, reducing downtime and maintenance costs.

Cost Efficiency: By controlling grain size, manufacturers can tailor the performance of their bushings to specific applications, avoiding unnecessary material costs and ensuring the right balance of 硬度 and toughness.

Grain Size Control in Production – The Future of Tungsten Carbide Bushings

As demand for more specialized and high-performance bushings increases, advances in grain size control technology will play a vital role.

New sintering techniques and additive manufacturing methods offer exciting possibilities for fine-tuning the material properties of tungsten carbide bushings.

These technologies allow manufacturers to produce bushings with tailored properties, offering optimal performance in specific applications.

结论

Grain size optimization is a critical factor in the production of high-quality tungsten carbide bushings.

By adjusting the grain size, manufacturers can create bushings that are specifically tailored for different applications, whether for superior wear resistance or shock resistance.

Understanding how to control grain size during production allows for better performance, longer lifespan, and cost savings, ultimately leading to more efficient and reliable industrial systems.

如果您想了解任何公司的更多详细信息,请随时 联系我们.