碳化钨衬套 are essential components in Electric Submersible Pumps (ESPs), particularly in harsh environments like sand-laden water. These bushings offer exceptional durability, 耐磨性, and corrosion protection.

As abrasive particles in the water can cause wear and damage to pump components, tungsten carbide bushings provide the reliability needed for extended operational life.

This blog explores why tungsten carbide is ideal for ESP thrust bearings and how it ensures better performance in such challenging conditions.

Challenges of Sand-Laden Water in ESP Systems

Sand-laden water can cause significant challenges in ESP systems. The presence of sand and other abrasive particles in the water increases the wear rate of pump components, particularly the thrust bearing bushings.

These components are critical for supporting the shaft and ensuring smooth rotation under high loads. Here’s why sand-laden water is such a problem:

1). Abrasive Wear

Sand and other particles in the water act as abrasives, leading to continuous wear on the bearing surfaces. This causes rough surfaces, which increases friction and leads to further damage.

2). Reduced Efficiency

As the bushings wear down, they can cause the pump to operate inefficiently. Increased friction leads to energy loss, reducing the overall performance of the pump.

3). Premature Failure

Without proper protection, the wear caused by sand particles can lead to the early failure of critical components. This results in expensive repairs and unplanned downtime.

Why Tungsten Carbide Is the Ideal Material for ESP Thrust Bearing Bushings

Tungsten carbide is a superior material for thrust bearing bushings, especially in sand-laden water environments. Here are the key reasons why tungsten carbide excels in these conditions:

1). 卓越 耐磨性

Tungsten carbide is one of the hardest materials available, making it highly resistant to wear and abrasion.

This is crucial when dealing with sand-laden water, as it helps maintain the integrity of the bushings over extended periods, even under abrasive conditions.

2). High 硬度 和耐用性

With a hardness of 1500-2000 HV, tungsten carbide’s hardness far exceeds that of the sand particles typically present in the water.

This means that the material can resist the abrasive impact from sand, significantly reducing the wear rate.

3). 耐腐蚀

While sand is an abrasive issue, water itself can cause corrosion in certain materials.

Tungsten carbide’s excellent resistance to corrosion ensures that even in harsh, water-saturated environments, the bushings will retain their strength and functionality.

4).热稳定性

Tungsten carbide maintains its structural integrity at high temperatures, which is crucial in ESP applications.

The high temperatures generated during pump operation can affect the performance of other materials, but tungsten carbide remains stable, even in high-temperature conditions.

How Tungsten Carbide Bushings Improve ESP Thrust Bearing Performance

Tungsten carbide bushings provide multiple advantages for ESP thrust bearings operating in sand-laden water.

These benefits contribute to longer operational life, fewer failures, and reduced downtime for maintenance.

1). Reduced Maintenance Costs

Because tungsten carbide bushings last longer and wear down more slowly than other materials, companies can save significantly on maintenance costs.

Reduced wear means fewer repairs and less frequent replacements, leading to overall savings.

2). Increased Pump Efficiency

With tungsten carbide bushings, the wear is minimized, resulting in lower friction and better efficiency. The pump operates more smoothly, improving overall performance and energy use.

3). Greater Reliability

Tungsten carbide’s durability makes it the ideal material for high-stress environments like sand-laden water.

Its ability to withstand abrasives and corrosion ensures reliable performance, which is crucial in preventing unexpected breakdowns and ensuring consistent pumping operations.

Other Considerations for ESP Thrust Bearing Selection

While tungsten carbide is an excellent choice for thrust bearing bushings, there are other factors to consider when selecting the right material for your ESP system:

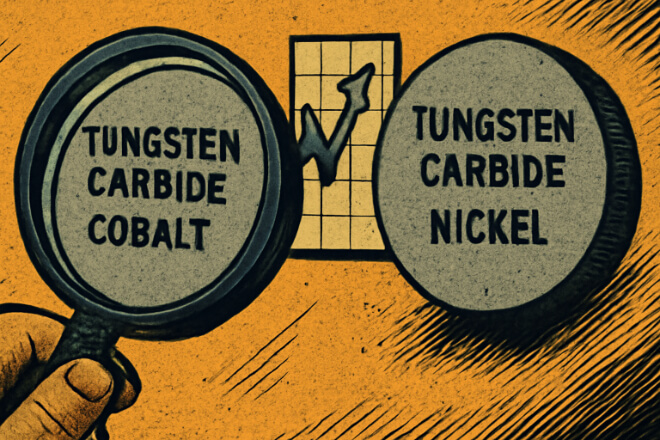

1). Material Composition

In addition to tungsten carbide, bushings are often made with various binders such as cobalt (WC-Co) or nickel (WC-Ni).

These binders can enhance certain properties, such as 韧性 或者 耐腐蚀. Choosing the correct binder material based on the operational environment is essential for optimal performance.

2). Bearing Design

The design of the bearing itself plays a critical role in ensuring that the thrust bearing can withstand high loads and abrasive conditions.

A well-designed bearing, paired with tungsten carbide bushings, can enhance the overall system’s performance.

3). Environmental Factors

Factors like temperature, pressure, and water chemistry can also affect the longevity of the bushings. Ensure that the chosen material and design can handle the specific operating conditions of your ESP.

结论

Tungsten carbide bushings are the optimal choice for ESP thrust bearings in sand-laden water environments.

Their high durability, wear resistance, and corrosion resistance significantly reduce maintenance costs, improve pump efficiency, and ensure reliable performance.

By choosing tungsten carbide bushings, companies can minimize downtime and enhance the lifespan of their ESP systems, making them a valuable investment for high-performance, long-term operation.

如果您想了解任何公司的更多详细信息,请随时 联系我们。