Tungsten carbide is a widely used material for manufacturing cutting tools, particularly in industries that require durability and 耐磨性, 例如 矿业, manufacturing, and construction.

One critical factor that affects the performance of tungsten carbide tips is the grain size of the material.

The grain size influences the tool’s strength, 韧性, and wear resistance, making it essential for manufacturers and engineers to understand how it impacts the material’s overall performance.

In this blog, we will explore how grain size affects tungsten carbide tips, the differences between fine and coarse grain tungsten carbide, and how to select the right grain size for specific applications.

What is Grain Size in Tungsten Carbide?

Grain size refers to the individual particles or crystals that make up the tungsten carbide material.

Tungsten carbide is a composite material made by combining tungsten metal with carbon, creating a solid structure of crystals.

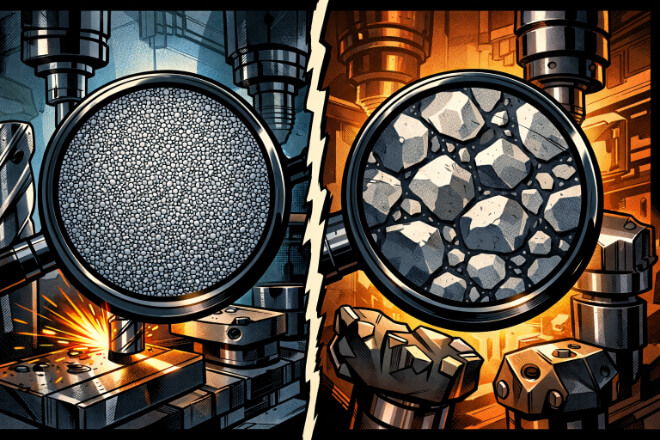

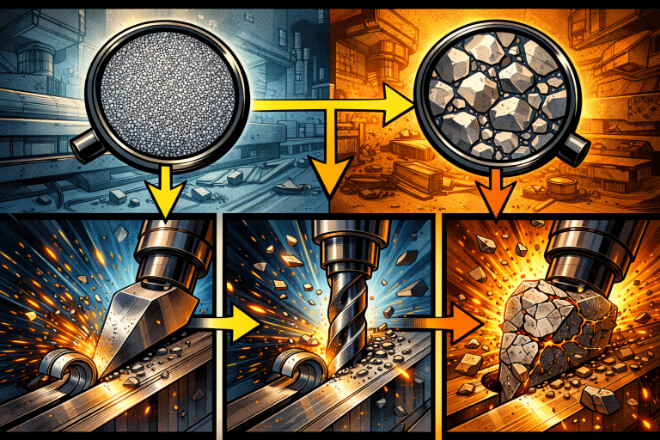

These crystals can vary in size depending on the manufacturing process, and the grain size is classified as either fine or coarse.

Fine Grain Tungsten Carbide: This material has smaller, more uniform crystals. It is known for its high strength and resistance to wear.

Coarse Grain Tungsten Carbide: This material has larger crystals and tends to be tougher but may have lower strength and 耐磨性 than fine-grain tungsten carbide.

Understanding grain size is key for selecting the right tungsten carbide tip for various applications.

The Effect of Grain Size on Strength and Toughness

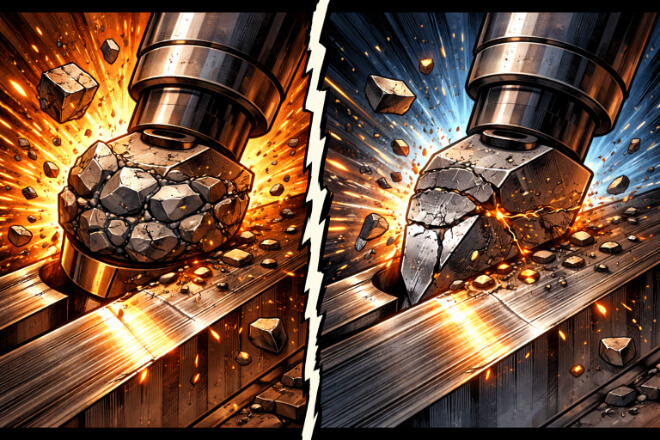

Grain size plays a significant role in the strength and toughness of tungsten carbide tips.

In general, smaller grain sizes (fine-grain tungsten carbide) enhance the material’s strength and 硬度, while larger grain sizes (coarse-grain tungsten carbide) improve 韧性 和抗冲击性。

Fine Grain Tungsten Carbide:

Fine-grain tungsten carbide tends to have better hardness and 耐磨性, making it ideal for cutting and machining hard materials.

However, it may be more prone to cracking under extreme impact or shock due to its brittleness.

Coarse Grain Tungsten Carbide:

Coarse-grain tungsten carbide offers better resistance to fractures and is less likely to crack under high impact or sudden changes in load.

However, it sacrifices some wear resistance and hardness, making it more suitable for applications with less frequent wear and impact.

The choice between fine and coarse grain depends on the specific requirements of the application, including the type of materials being processed and the conditions under which the tool will be used.

Grain Size and Wear Resistance in Tungsten Carbide Tips

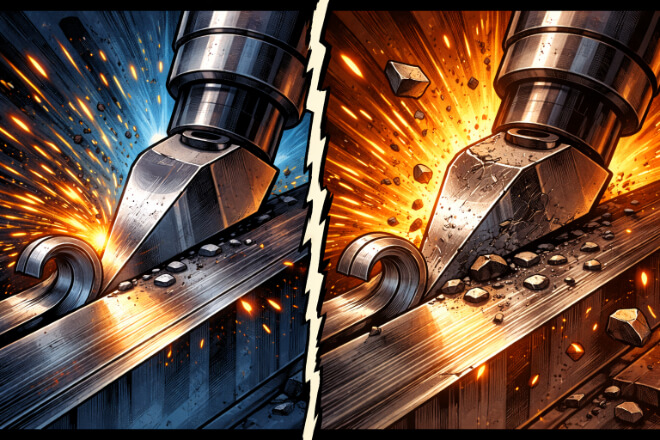

耐磨性 is one of the most critical factors in the performance of cutting tools. The finer the grain size, the harder and more resistant to wear the tungsten carbide will be.

This is why fine-grain tungsten carbide is often used for applications requiring extended tool life in harsh, abrasive environments.

Fine Grain:

The small, tightly packed crystals in fine-grain tungsten carbide provide more resistance to abrasive forces.

As a result, fine-grain tungsten carbide tips can retain their sharpness for longer periods and reduce the frequency of tool replacements.

Coarse Grain:

Coarse-grain tungsten carbide is more likely to lose its sharpness more quickly due to the larger crystals. However, it can still withstand high-impact conditions better than fine-grain carbide.

Thus, for applications involving frequent abrasive contact (such as cutting or grinding), fine-grain tungsten carbide tips are preferred due to their superior wear resistance.

Grain Size and Impact Resistance in Tungsten Carbide Tips

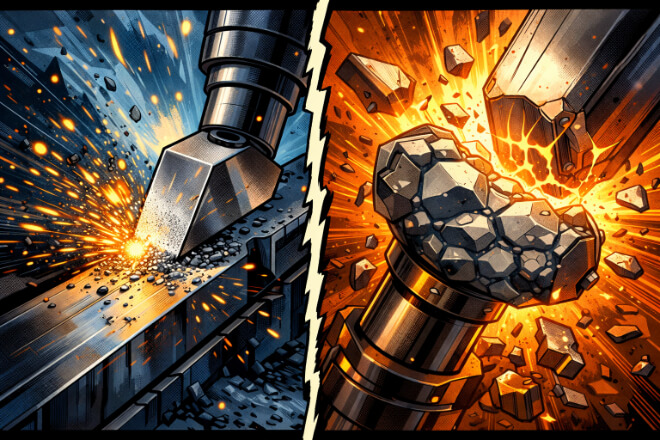

Impact resistance is another important factor that influences the performance of tungsten carbide tips.

Tungsten carbide, although very hard, can be brittle, especially when subjected to sudden impacts. This is where the grain size comes into play.

Fine Grain Tungsten Carbide:

While fine-grain tungsten carbide is harder and more 耐磨, it is more susceptible to cracking or chipping when exposed to heavy impacts or shock loads.

Coarse Grain Tungsten Carbide:

Coarse-grain tungsten carbide is tougher and better able to withstand sudden forces without fracturing.

This makes it ideal for applications where the tool is likely to experience high-impact forces, such as in mining, dredging, or construction.

选择正确的 粒度 is crucial in ensuring that the tool is not only resistant to wear but also capable of withstanding high-impact forces without breaking or chipping.

How to Choose the Right Grain Size for Your Application

Selecting the appropriate grain size for tungsten carbide tips depends on the specific demands of the application. Here are some guidelines to help in choosing the right grain size:

For High 耐磨性: Fine-grain tungsten carbide is preferred for applications where wear resistance is critical, such as in machining hard materials, grinding, and cutting.

为了 韧性 and Impact Resistance: Coarse-grain tungsten carbide is ideal for applications that require resistance to impact and shock, such as mining and construction tools.

Balanced Performance: For applications that require a balance of wear resistance and impact resistance, a medium-grain tungsten carbide may offer the best compromise between the two.

Understanding the specific requirements of your application—whether it involves high wear, impact forces, or a combination of both—will help you choose the right grain size for optimal performance.

结论

Grain size plays a crucial role in the performance of tungsten carbide tips, affecting their hardness, wear resistance, and impact resistance.

Fine-grain tungsten carbide excels in applications where wear resistance and longevity are essential, while coarse-grain tungsten carbide is better suited for high-impact environments that require toughness.

By selecting the appropriate grain size, manufacturers can optimize the performance of tungsten carbide tips to meet the demands of various industries, from mining and construction to machining and manufacturing.

如果您想了解任何公司的更多详细信息,请随时 联系我们。