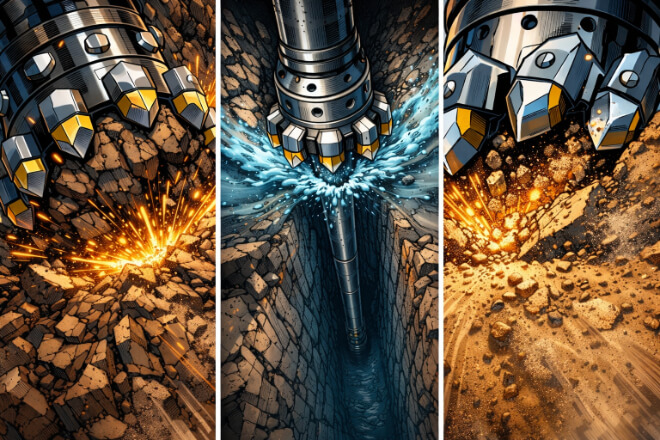

在 石油和天然气 industry, drilling is one of the most critical operations for exploring and extracting valuable resources from deep beneath the Earth’s surface. Tungsten carbide tips are integral to drilling tools due to their durability, 硬度, 和 耐磨性.

These properties make tungsten carbide tips essential for high-performance drilling in tough, abrasive environments.

In this blog, we will explore the role of tungsten carbide tips in oil and gas drilling, how they improve drilling efficiency, and why they are the preferred choice for drill bits in this challenging industry.

Why Tungsten Carbide Tips Are Essential for Oil and Gas Drilling

The harsh conditions encountered during oil and gas drilling require tools that are capable of withstanding high pressures, temperatures, and abrasive materials.

Tungsten carbide tips are ideal for these applications due to their remarkable properties.

1). Unmatched 硬度

Tungsten carbide is one of the hardest materials available, making it perfect for drilling through tough formations such as rock, shale, and cemented layers.

The hardness of carbide tips ensures that drill bits can maintain their cutting edges for extended periods without losing their sharpness, even when drilling through hard rock and deep formations.

2). Outstanding 耐磨性

Drilling for oil and gas subjects tools to continuous friction and high abrasion from the material being drilled.

Tungsten carbide tips are highly resistant to wear, ensuring they retain their cutting ability over time.

This wear resistance is essential in preventing rapid tool degradation, which can lead to downtime and higher operational costs.

3). Heat Resistance and Durability

High-speed drilling operations generate significant heat, which can cause traditional tools to soften and lose their cutting efficiency.

Tungsten carbide tips maintain their hardness and integrity even under extreme heat, ensuring reliable performance and reducing the likelihood of tool failure during extended drilling sessions.

Performance Benefits of Tungsten Carbide Tips in Drilling Operations

Tungsten carbide tips offer numerous performance benefits that are crucial for successful oil and gas drilling operations.

These benefits help improve drilling efficiency, reduce downtime, and increase the lifespan of drilling tools.

1). Enhanced Drilling Speed and Efficiency

Tungsten carbide tips allow drilling tools to operate at higher speeds without losing performance.

This increased cutting efficiency enables faster drilling times, reducing the total time required to reach the target depth.

The quicker the drilling process, the more efficient the operation, allowing for greater production and lower costs.

2). Reduced Tool Replacements

The exceptional hardness and 耐磨性 of tungsten carbide tips extend the lifespan of drill bits, reducing the frequency of tool replacements.

This is particularly important in oil and gas drilling, where downtime for tool changes can be costly.

The ability to use the same tool for a longer period helps reduce operational costs and increase the overall efficiency of the drilling operation.

3). Improved Precision and Stability

Tungsten carbide tips provide better stability during drilling, ensuring that the drilling process remains accurate and on target.

The rigidity and 韧性 of carbide tips reduce the chances of tool deflection or bending, leading to more precise drilling and less risk of errors.

This stability ensures that the drilling process remains consistent, which is essential for reaching the desired depths and extracting oil and gas efficiently.

Tungsten Carbide Tips in Different Drilling Environments

石油和天然气 drilling often takes place in challenging environments where the materials being drilled are highly variable.

Tungsten carbide tips are well-suited for these environments, offering performance benefits that are unmatched by other materials.

1). Drilling Through Hard Rock and Shale

One of the most challenging aspects of oil and gas drilling is cutting through hard rock and shale.

Tungsten carbide tips are highly effective in these environments due to their 硬度 和 resistance to wear.

The ability to drill through hard formations without compromising tool life is critical for maintaining drilling efficiency and minimizing downtime.

2). Deep Well and High-Pressure Drilling

In deep well drilling, high-pressure environments require tools that can withstand extreme stresses. Tungsten carbide tips provide the strength and durability necessary to perform in these conditions.

Their impact resistance allows them to handle the stresses of deep well drilling, where sudden pressure changes can cause tools to fail if not made from the right material.

3). Drilling in Abrasive Environments

Many oil and gas drilling sites involve abrasive materials such as sand or gravel, which can wear down drilling tools quickly.

Tungsten carbide tips excel in abrasive environments, providing superior wear resistance and ensuring that the tools maintain their cutting ability even when exposed to these harsh conditions.

Maximizing the Performance of Tungsten Carbide Tips in Drilling

To ensure that tungsten carbide tips deliver the best performance during drilling operations, it’s essential to optimize their use and maintain them properly.

1). Optimizing Drilling Parameters

Adjusting the cutting speed, feed rate, and weight on bit can help maximize the performance of tungsten carbide tips.

Operating at the right parameters ensures that carbide tips work efficiently, reducing excessive heat generation and wear.

Optimized drilling conditions lead to longer tool life and more efficient drilling.

2). Routine Tool Inspections

Regular inspections of tungsten carbide tips for wear, cracks, or damage help identify issues before they cause tool failure.

Proactive maintenance ensures that the tips continue to function effectively, reducing the risk of downtime or operational delays caused by unexpected tool failure.

3). Tool Reconditioning and Resharpening

When tungsten carbide tips begin to lose their sharpness, reconditioning or resharpening the tips can restore their cutting ability.

Resharpening carbide tips instead of replacing them entirely can save on operational costs and extend tool life, making it a cost-effective solution for maintaining drilling performance.

Applications of Tungsten Carbide Tips in Oil and Gas Drilling

Tungsten carbide tips are used in various drilling tools for oil and gas exploration, each designed to meet specific challenges in different drilling environments.

1). Drill Bits

Tungsten carbide tips are primarily used in drill bits, the most critical component of the drilling process.

这 硬度 and durability of carbide tips enable them to cut through tough rock formations, increasing the speed and efficiency of drilling operations.

2). Downhole Tools

Tungsten carbide tips are also used in downhole tools, such as reamers and stabilizers.

These tools help maintain the integrity of the wellbore, and the 韧性 of tungsten carbide ensures that these tools can withstand the stresses encountered during deep well drilling.

3). Core Drilling

In core drilling, tungsten carbide tips are used to collect rock and soil samples from deep underground.

The durability and precision of carbide tips allow for accurate core sampling without damaging the samples, which is essential for geological analysis.

结论

Tungsten carbide tips play a vital role in the oil and gas industry, providing the durability, wear resistance, and heat tolerance required for successful drilling operations.

By using tungsten carbide tips, drilling teams can enhance drilling performance, reduce downtime, and extend tool life, all while cutting through tough rock and other hard formations.

The efficiency and reliability of carbide tips make them the preferred choice for oil and gas drilling, helping businesses optimize their drilling operations and achieve long-term success.

如果您想了解任何公司的更多详细信息,请随时 联系我们。