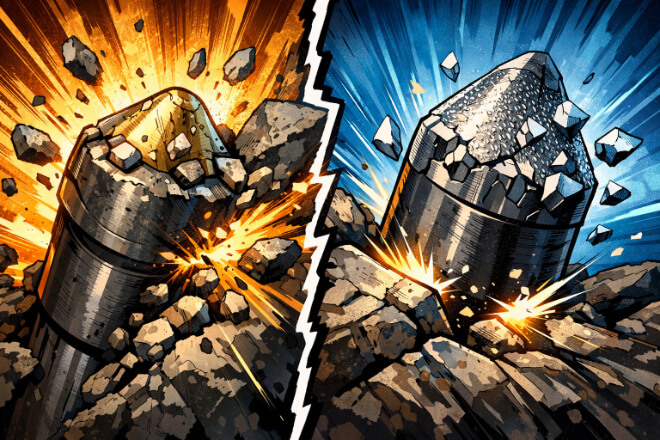

In industrial applications where cutting and drilling tools endure extreme conditions, choosing the right material is crucial for ensuring performance and longevity.

Tungsten carbide tips and diamond-coated tips are two popular options. Both offer exceptional 硬度 and durability, but their specific advantages make them more suitable for certain tasks.

In this blog, we will compare tungsten carbide tips and diamond-coated tips to determine which material is better suited for various industrial applications.

What are Tungsten Carbide Tips?

Tungsten carbide is a compound made from tungsten and carbon, known for its exceptional 硬度 和 耐磨性.

It is often used in cutting tools, drilling equipment, and mining tools. Tungsten carbide tips are highly durable and effective in high-friction environments, making them ideal for applications involving metals, concrete, and other hard materials.

The main advantage of tungsten carbide is its combination of hardness and 韧性. While it is not as hard as diamond, it is much tougher and can withstand impact without shattering.

This balance of toughness and wear resistance makes tungsten carbide tips versatile and reliable.

What are Diamond-Coated Tips?

Diamond-coated tips are made by applying a thin layer of industrial diamond to a base material, often tungsten carbide or steel. The diamond coating provides the tool with superior 硬度 和 耐磨性.

Diamond-coated tips are particularly effective for applications involving abrasive materials, such as composites, ceramics, and certain metals.

Diamond coatings offer a number of advantages, particularly their ability to maintain a sharp edge over time.

The hardness of diamond, rated as the hardest known material, ensures that diamond-coated tips resist wear even in the harshest cutting conditions.

However, diamond coatings are brittle, which means they are more susceptible to chipping or cracking under impact.

Durability and Wear Resistance: Tungsten Carbide vs Diamond-Coated Tips

Both tungsten carbide and diamond-coated tips are highly durable, but their wear resistance differs depending on the application.

碳化钨:

Tungsten carbide tips excel in applications where toughness and impact resistance are essential.

They are ideal for tasks where the tool will be subjected to heavy wear, such as cutting through tough metals, drilling through concrete, or mining.

Tungsten carbide is highly resistant to abrasion, making it the preferred choice for tools exposed to harsh conditions that involve both friction and impact.

Diamond-Coated Tips:

Diamond-coated tips are the best choice for high-precision cutting and applications that involve extremely abrasive materials.

Diamond coatings provide superior 耐磨性, ensuring that the cutting edge remains sharp longer than tungsten carbide.

However, diamond-coated tips are more fragile and can break or chip when exposed to high-impact forces.

Toughness vs Hardness: Key Differences

The main difference between tungsten carbide and diamond-coated tips lies in their toughness versus hardness balance.

碳化钨:

Tungsten carbide is known for its 韧性, which makes it better suited for impact-heavy applications.

Its ability to absorb shocks and resist cracking under pressure allows it to perform well in drilling, mining, and machining operations where the tools may be subjected to sudden force.

Diamond-Coated Tips:

Diamond-coated tips, on the other hand, excel in 硬度. The diamond coating allows the tool to maintain a sharp cutting edge even after prolonged use.

However, the brittleness of the diamond coating means that these tools can break or chip under high-impact conditions.

For applications that involve less impact and more abrasion, diamond-coated tips offer superior performance.

Applications of Tungsten Carbide Tips

Tungsten carbide tips are commonly used in applications where both wear resistance and toughness are necessary. Some of the most common applications include:

矿业: Tungsten carbide tips are ideal for mining tools because they can withstand the extreme conditions and abrasiveness encountered while drilling into rock or soil.

建造: Tungsten carbide is often used in cutting tools and drill bits for construction, especially when dealing with tough materials like concrete and steel.

Machining and 金工: Tungsten carbide tips are effective for cutting, grinding, and machining metals, where impact and abrasion resistance are crucial.

Applications of Diamond-Coated Tips

Diamond-coated tips shine in applications that require high precision and exceptional wear resistance.

They are ideal for industries where the cutting tool needs to maintain its sharpness over extended periods. Common applications include:

航天 和 汽车: Diamond-coated tips are used in machining complex parts and components made from hard materials, including titanium and high-strength alloys.

电子产品 Manufacturing: The sharpness and durability of diamond-coated tips make them ideal for cutting and drilling in electronics manufacturing, especially for materials like silicon and ceramics.

Composites and Ceramics: Diamond coatings are highly effective when cutting through composite materials and ceramics, which are much more abrasive than metals.

Cost Considerations: Tungsten Carbide vs Diamond-Coated Tips

When it comes to cost, tungsten carbide tips are generally more affordable than diamond-coated tips.

Tungsten carbide is a well-established material, and its manufacturing processes are well-developed, making it a cost-effective option for many industrial applications.

In contrast, diamond-coated tips are typically more expensive due to the high cost of diamond coatings and the more complex manufacturing process.

However, the increased 耐磨性 and longer tool life of diamond-coated tips can offset the initial cost in certain high-precision applications where long-term performance is crucial.

结论

Both tungsten carbide tips and diamond-coated tips have their strengths and weaknesses, making them suitable for different industrial applications.

Tungsten carbide is the better choice for applications requiring toughness and impact resistance, while diamond-coated tips excel in situations where hardness and wear resistance are the most important factors.

Understanding the specific needs of your application will help you make the right choice between these two exceptional materials.

如果您想了解任何公司的更多详细信息,请随时 联系我们。