在数控加工中,精度和生产效率至关重要。无论您是生产单个高精度零件,还是运行整条生产线,切削刀具都发挥着重要作用。有一种材料脱颖而出:碳化钨。

越来越多的机械车间和制造商正在转向 碳化钨切削刀具——这是有充分理由的。这些工具不仅功能更强大,还能帮助节省时间、降低成本并提高质量。

本文将以清晰、简单的方式向您介绍在 CNC 加工中使用碳化钨切削刀具的真正好处。

1. 更长的刀具寿命 = 更少的更换次数

碳化钨工具的最大优点之一是其使用寿命极长。

它们的使用寿命比高速钢 (HSS) 或钴工具长得多——尤其是在切割坚硬或磨蚀性材料时。

您可以在生产过程中花费更少的时间更换工具,而花更多的时间来保持机器运转。

更少的中断意味着更长的正常运行时间,更少的刀具更换频率意味着节省成本。尽管硬质合金刀具最初成本较高,但它们的使用寿命却是传统刀具的数倍。

这种持久的性能使它们成为小型机械车间和大型生产线的首选。

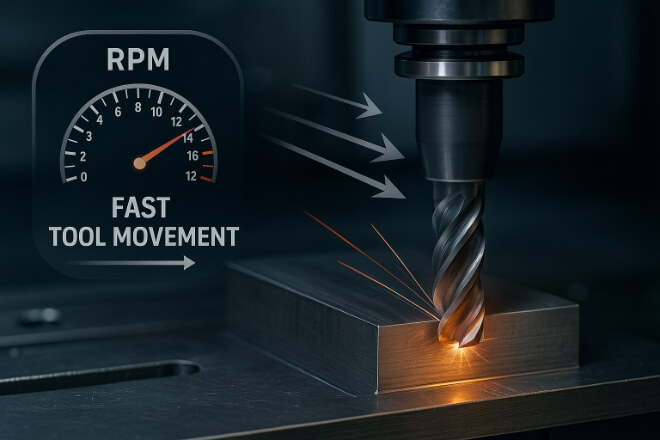

3.更高的切削速度和进给率

另一大优势是速度。硬质合金刀具的加工速度和进给率比钢制刀具更高。

这意味着您可以更快地完成工作,每小时生产更多的零件,并更轻松地满足紧迫的期限。

这些工具即使以每分钟数千转的速度旋转也能保持锋利,因此您不必为了速度而牺牲质量。

这在时间就是金钱的数控加工中尤其有用。更快的加工速度有助于提高生产效率,同时又不牺牲精度。

4. 更好的表面光洁度 = 更少的后处理

更锋利的刀具带来更干净的切割效果,而这正是硬质合金刀具的优势所在。由于硬质合金刀具拥有极佳的刃口保持力,因此能够实现更平滑、更精准的加工效果。

这意味着更少的毛刺和粗糙边缘,也意味着更少的研磨、抛光或返工的需要。

当您的零件干净且准备好从机器上取下时,您可以节省时间、减少劳动力并加快交货速度。

在需要高质量表面处理的行业(例如医疗或航空航天),这种好处怎么强调也不为过。

5.减少刀具破损和停机时间

钢制刀具在压力下容易弯曲或崩刃,而碳化钨刀具的刚性则要高得多。这种额外的刚性使得它们在切割过程中不易断裂。

这很重要,因为刀具损坏可能会损坏零件、损坏机器,甚至导致生产停顿。硬质合金刀具有助于降低这些风险。

它们在重载下依然保持稳定,使您的加工过程更加可靠。更少的破损意味着更少的延误、更少的浪费,以及对工作流程的信心。

6. 在 CNC 自动化中效果更佳

CNC 自动化就是在很少或根本不需要人工监督的情况下保持机器平稳运行。

在这些设置中,您需要能够长时间运行甚至整夜运行而不会发生故障的切削工具。

碳化钨刀具非常适合此用途。它们能够长时间保持性能,是无人值守加工和自动化生产环境的理想选择。

当机器持续运转、工具持续切削时,您的生产力就会提高,而无需增加劳动力。

7.优异的耐热性

机械加工会产生大量的热量。如果您的刀具无法承受这些热量,就会变软、变钝或变形。而这正是碳化钨的真正优势所在。

它能够承受高温,即使在严苛的切削条件下也能保持锋利。这使得它非常适合高速干式加工或冷却液流量受限的作业。

当您的工具耐热时,它的使用寿命更长、切割更稳定,这意味着更好的零件和更少的问题。

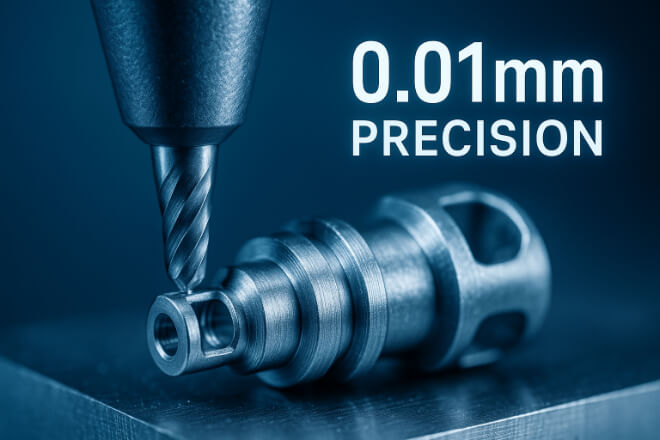

8. 非常适合精密加工

精密作业不容有任何差错。每一次切割都必须恰到好处。这正是硬质合金刀具的用武之地。

其刚性和锋利度确保了高精度和可重复的性能。无论您制造的是航空航天零件、医疗植入物还是精密机械部件,您都可以依靠硬质合金来满足严格的公差要求。

即使是最小的特征,硬质合金刀具也能保持精准。这使得它们成为关键、高精度 CNC 加工的可靠之选。

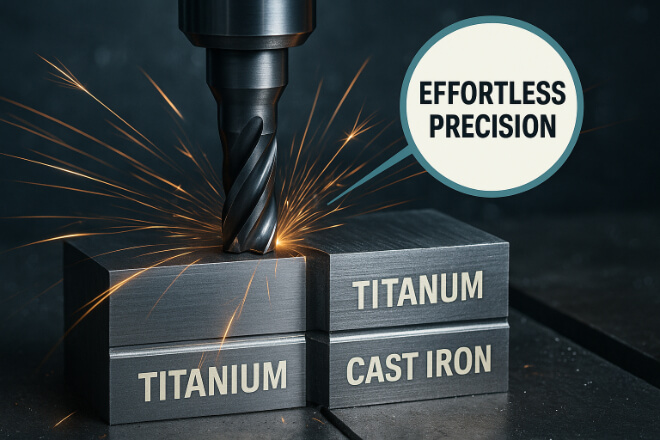

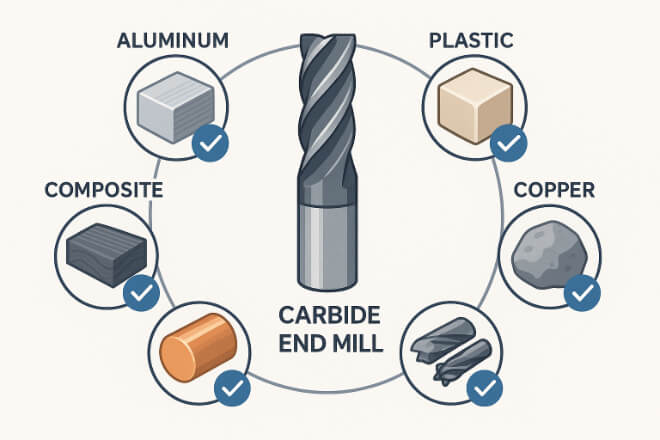

9. 兼容多种材料

多功能性是其另一大优势。碳化钨刀具不仅仅适用于钢材加工。

它们可以与多种材料配合使用,包括铝、铜、塑料、复合材料甚至石材。

这意味着您可以在不同的工作和材料中使用同一套工具。

如果您经营的是混合材料车间或经常更换项目,这种灵活性可以简化您的设置并减少工具更换次数。一把工具,多种用途。

10. 生产车间的投资回报率更高

对于关心产量、可靠性和成本效益的生产车间来说,碳化钨工具是最有意义的。

它们前期成本可能较高,但其性能足以弥补这一缺陷。您可以提高加工速度,获得更一致的零件,减少刀具更换,避免停机,并降低人工和精加工成本。

从整体来看,硬质合金刀具可以为您带来长期更好的投资回报。

最后的想法

碳化钨切削刀具在数控加工中具有明显而强大的优势。

它们使用寿命更长,可切割更坚硬的材料,工作速度更快,并能获得更佳的表面效果。它们可减少停机时间,在自动化应用中表现优异,并且能够轻松应对高温。

无论您是在加工复杂的航空航天零件还是进行日常生产工作,硬质合金刀具都能帮助您更智能、更快速、更自信地工作。

如果您想了解任何公司的更多详细信息,请随时 联系我们.