碳化钨切削刀具 are essential in modern machining. Known for their incredible hardness and strength, these tools are used in everything from 航天 parts to 汽车 成分。

But how do they actually work? What makes them so reliable, and why are they chosen over other tool materials?

In this blog, we’ll break it all down—how tungsten carbide tools are made, how they perform in cutting, and what helps them last longer.

Whether you run a machine shop or manage industrial production, understanding how these tools work can help you make better purchasing and operational decisions.

什么是碳化钨?

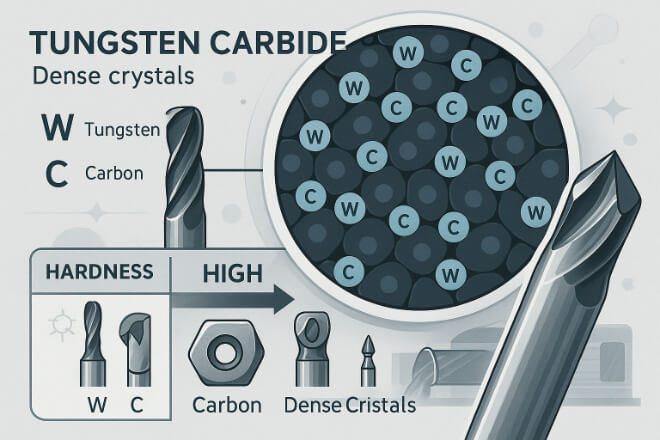

Tungsten carbide is a compound made of tungsten (W) and carbon (C). When fused, they form a material that’s almost as hard as diamonds.

But unlike diamonds, tungsten carbide also has excellent toughness. This makes it perfect for cutting through hard metals without breaking or chipping easily.

Most tungsten carbide used in tools is mixed with a binder, usually cobalt, which helps hold the carbide particles together and adds strength under pressure.

主要属性:

How Tungsten Carbide Cutting Tools Are Made

The manufacturing process of tungsten carbide tools involves several key steps:

Powder Preparation: Fine tungsten and carbon powders are mixed, then blended with cobalt.

Pressing: The powder is compressed into the shape of the desired tool (or a blank).

Sintering: The pressed part is heated to around 1400–1500°C. This bonds the particles together, creating a dense and strong structure.

Grinding and Finishing: Tools are then ground to precise shapes and tolerances.

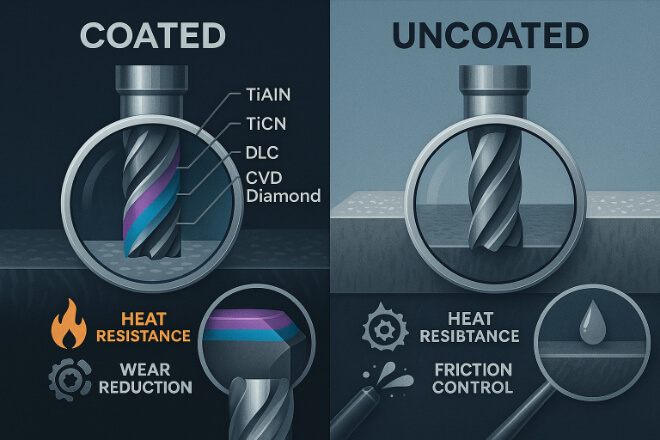

Coating (optional): Some tools receive coatings like TiAlN or DLC to improve heat resistance and reduce friction.

This process creates a cutting tool that can perform under high speeds and extreme loads.

How Tungsten Carbide Tools Work in Cutting

Tungsten carbide tools cut by shearing material away from a workpiece. As the tool rotates (in drills, end mills, etc.) or moves linearly (in inserts or turning tools), it removes material in the form of chips.

What makes carbide tools effective?

硬度: Can cut hardened steels and superalloys.

Heat resistance: Performs well at high cutting speeds.

Edge stability: Maintains sharpness longer than HSS or ceramic tools.

耐磨性: Reduces tool change frequency and downtime.

In high-speed or heavy-duty cutting, carbide tools remain stable while resisting wear, heat softening, and plastic deformation.

碳化钨切削刀具的类型

Carbide is used in many forms depending on the operation:

| 工具类型 | 常见用途 |

|---|---|

| 硬质合金刀片 | Turning, milling, and grooving |

| End Mills | Milling of metal and composites |

| 钻头 | High-speed and deep hole drilling |

| 铰刀 | Precision finishing of holes |

| 伯尔斯 | Deburring and light material removal |

| Taps & Thread Mills | Threading in tough alloys and steels |

These tools are available in standard geometries or can be custom-designed for specific jobs.

The Role of Coatings in Performance

While bare tungsten carbide performs well, coatings can take it to the next level. Popular coatings include:

TiAlN (Titanium Aluminum Nitride): High heat resistance.

TiCN (Titanium Carbo-Nitride): Good 耐磨性。

DLC (Diamond-Like Carbon): Reduces friction, ideal for aluminum and soft metals.

CVD Diamond: For cutting abrasive materials like carbon fiber or ceramics.

Coatings help:

延长刀具寿命

Reduce heat buildup

Allow for faster cutting speeds

Improve surface finish

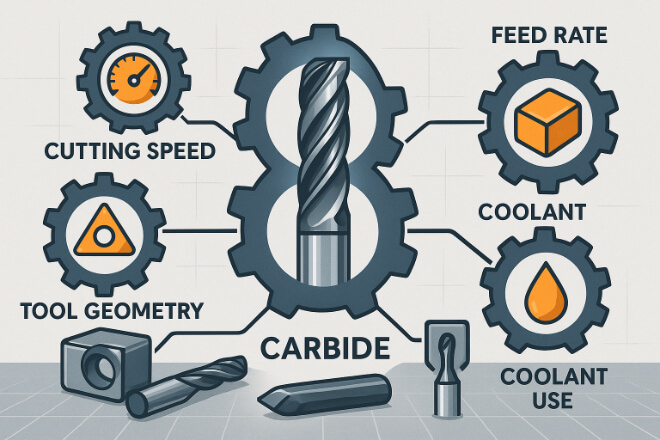

Factors That Affect Cutting Tool Performance

Tungsten carbide tools are strong, but their performance depends on several factors:

Cutting Speed: Higher speeds need better coatings and heat resistance.

Feed Rate: Affects tool pressure and heat generation.

Material Being Cut: Hardened steels, alloys, or aluminum all react differently.

Coolant Use: Helps reduce temperature and flush away chips.

Tool Geometry: Impacts how the tool engages the material.

Optimizing these factors can improve tool life, reduce downtime, and lower production costs.

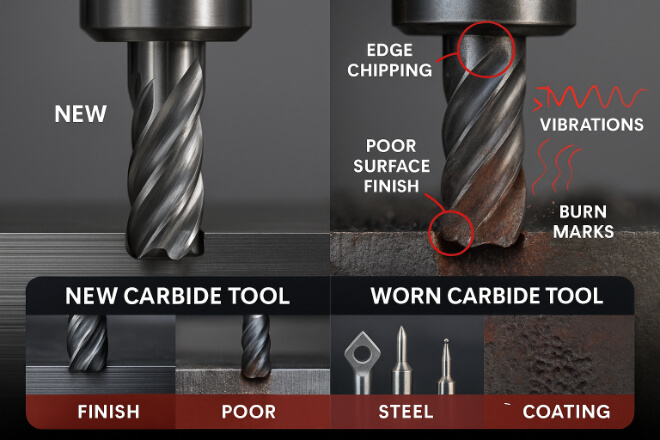

Common Signs of Wear and Tool Failure

Understanding when to replace or regrind your tools is important. Look out for:

Dull or chipped cutting edges

Poor surface finish on workpieces

Unexpected tool breakage

Increase in machine vibration or noise

Burn marks or discoloration

Using tools beyond their life can lead to more damage—both to the part and the machine.

Tool Maintenance and Storage Tips

To get the most out of your tungsten carbide cutting tools, follow these tips:

Clean tools after each use

Store them in dry, cushioned containers

Keep tools separated to prevent edge damage

Avoid humid environments to prevent cobalt leaching

Label tools by usage status (new, used, for regrind)

Proper maintenance = longer tool life + better machining results.

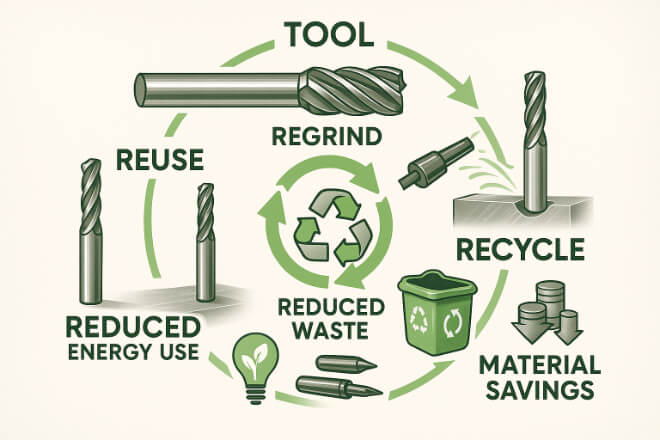

Environmental Benefits of Long-Lasting Tools

Using tungsten carbide tools can also support sustainability goals. Here’s how:

Less frequent replacements = less manufacturing waste

Regrinding options extend life and reduce resource use

Recycling programs exist for used carbide tools

More efficient cutting = lower energy usage per part

结论

Tungsten carbide cutting tools work through a smart mix of hardness, precision, and durability.

From how they’re made to how they cut, each detail is engineered for maximum performance under tough conditions.

When used correctly—with the right speeds, coatings, and maintenance—they can outperform other cutting materials by a large margin.

That’s why decision-makers in machining and manufacturing choose carbide tools to stay ahead of production demands.

Looking for reliable tools that deliver consistent results? Check out 雷托普兹 to find tungsten carbide solutions for your workshop or production floor.