In the world of metal cutting, precision matters. So does tool life, surface finish, and overall production cost.

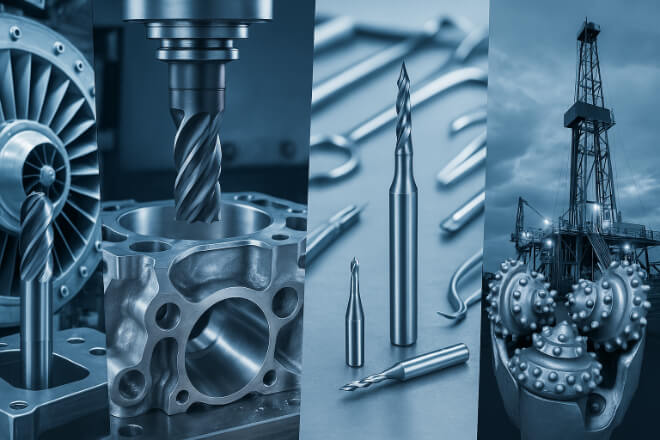

That’s where 碳化钨切削刀具 shine. These tools are used by professionals in 航天, 汽车, 医疗的, 石油和天然气, and many other industries.

But why are they so popular? Why are so many manufacturers switching from high-speed steel (HSS) or other materials to tungsten carbide tools?

In this blog, we’ll explain the top reasons why these tools stand out, how they improve your machining performance, and what benefits you can expect from making the switch.

Extreme Hardness for Better Cutting Performance

Tungsten carbide is one of the hardest tool materials in the world. It ranks around 9 on the Mohs scale, just below diamond.

This extreme hardness allows the tool to:

Cut tough materials like stainless steel, titanium, and cast iron

Maintain its edge longer than HSS or ceramic tools

Operate at higher speeds without dulling quickly

For decision-makers, this translates to higher efficiency and fewer tool changes during production.

High Wear Resistance = Longer Tool Life

Tungsten carbide tools resist wear even in high-friction or high-heat applications.

This means your tools stay sharp longer and can handle repeated passes without losing precision.

Here’s a quick comparison:

| 材料 | Average Tool Life | Best Used For |

|---|---|---|

| 高速钢(HSS) | 低至中等 | Soft metals, wood |

| 碳化物 | 高的 | Hard metals, long runs |

| 陶瓷制品 | 中等的 | 高速精加工 |

With carbide tools, you reduce how often you stop production to replace tools—saving you both time and labor cost.

Heat Resistance Improves Cutting Speeds

One major reason why carbide performs well in high-speed machining is its resistance to heat.

Tungsten carbide can handle temperatures above 1000°C without softening.

This gives your machine operators the ability to:

Increase feed rates

Reduce cycle times

Improve production output

Less heat buildup also means less deformation in your parts, leading to better surface finishes.

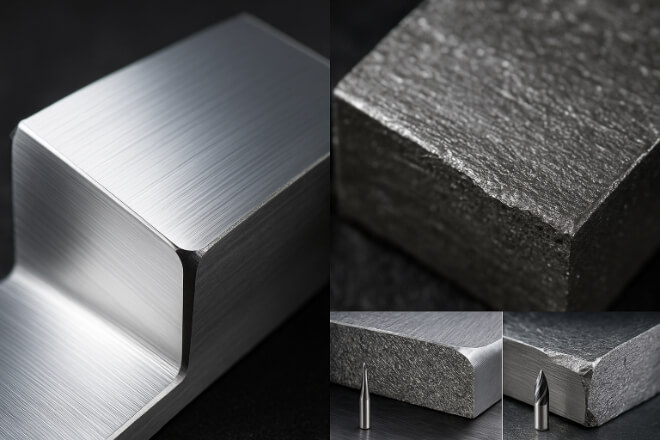

Excellent Surface Finish

A sharp, strong tool creates clean cuts. Carbide tools produce smoother surface finishes compared to dulling HSS or cheaper alternatives.

This matters in industries where the final product is critical—like aerospace parts, surgical tools, and injection molds.

Smoother finishes mean:

Less post-processing (grinding, polishing)

Higher precision parts

Better mating of components

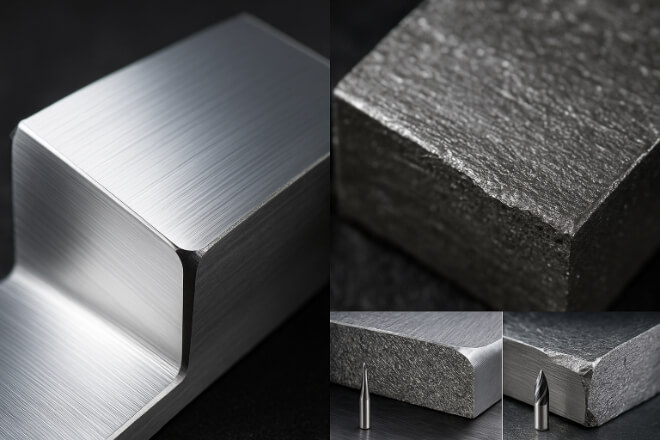

Versatile Tool Geometry Options

Tungsten carbide can be ground into a wide variety of shapes and geometries—flat end mills, ball nose, inserts, drills, reamers, and more.

That flexibility helps you tackle:

Grooving

Slotting

Facing

Profiling

Threading

No matter your application, carbide tools can be customized to fit your specific machining requirements.

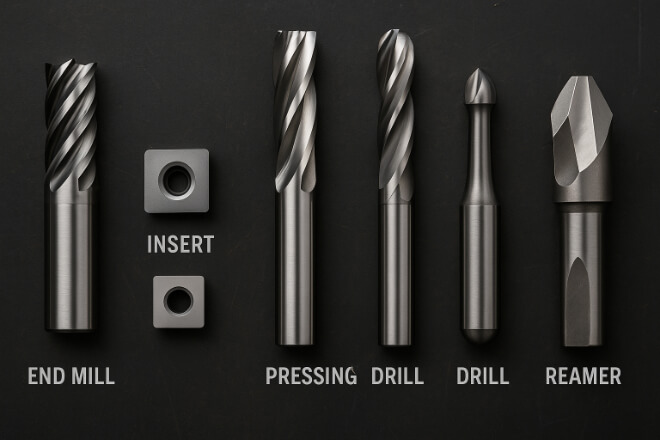

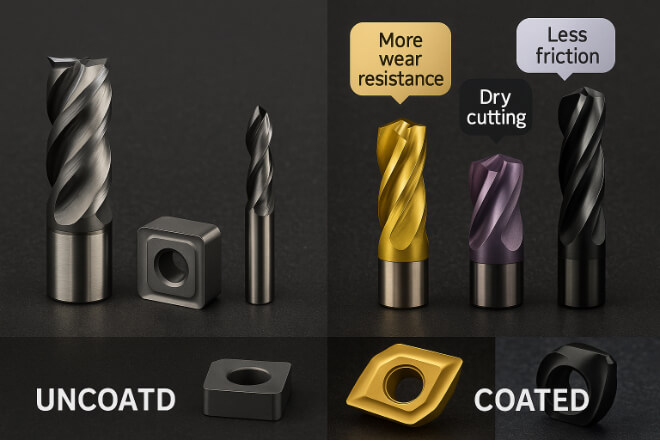

Compatibility with Advanced Coatings

Carbide tools are often coated with materials like TiN (Titanium Nitride), TiAlN (Titanium Aluminum Nitride), or diamond-like carbon (DLC).

These coatings:

Boost 耐磨性

Reduce friction

延长刀具寿命

Allow dry machining in some cases

Your productivity goes up while tool costs come down in the long run.

| 涂层 | Main Benefit | Ideal Use Case |

|---|---|---|

| 锡 | 耐磨性 | 普通加工 |

| 氮化铝钛 | 耐热性 | High-speed cutting |

| 扩展内容 | Low friction | Aluminum or plastics |

Ideal for Automation and CNC Machining

If you rely on CNC machining or robotic automation, tungsten carbide tools are the smart choice. Their consistency and durability make them perfect for:

Unattended machining

Long production runs

Tight tolerance parts

When your tools last longer and require fewer changes, your machines can keep running without constant supervision.

Better Cost-Per-Part Ratio

Carbide tools may have a higher initial price compared to HSS, but the overall cost-per-part is much lower.

That’s because they:

Last longer

Run faster

减少停机时间

Improve part quality

So instead of paying less upfront and more over time, you invest smartly from the beginning.

Wide Industrial Applications

Tungsten carbide cutting tools are used across many industries including:

汽车: Engine blocks, transmission cases

航天: Turbine blades, landing gear components

医疗的: Surgical instruments, orthopedic implants

Oil & Gas: Drill bits, valves

General Manufacturing: Dies, molds, machine parts

No matter your field, there’s a place for carbide tools in your process.

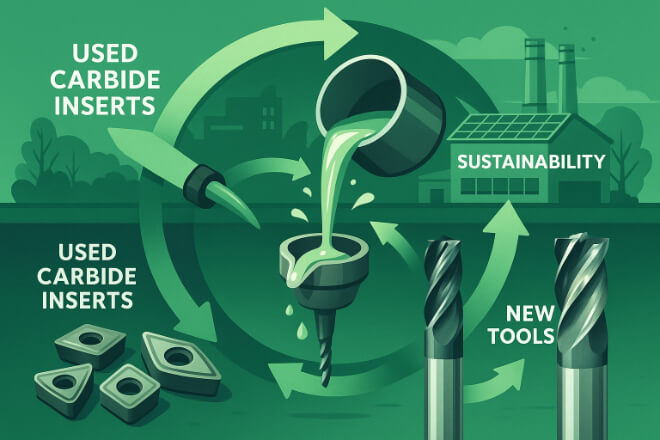

Eco-Friendly and Recyclable

Did you know tungsten carbide is recyclable?

Many manufacturers offer buy-back or recycling programs for used tools. This reduces environmental impact and gives back some cost to your operation.

Recycling programs:

Reduce mining of raw materials

Lower carbon footprint

Support sustainability goals

最后的想法

Tungsten carbide cutting tools are a smart investment for any company focused on performance, quality, and efficiency.

Their advantages—like long tool life, better surface finish, heat resistance, and cost-effectiveness—make them ideal for modern manufacturing environments.

Looking to upgrade your tool game? Explore premium tungsten carbide tools backed by expert support at 重新顶部。