介绍

Tungsten carbide cutting tools are essential in modern manufacturing. They are hard, strong, and long-lasting, which makes them perfect for cutting metals, wood, composites, and more. This guide will help you understand the different types of tungsten carbide tools, how they are used, and which one is best for your job.

If you are working in CNC machining, woodworking, mining, oil & gas, or any other industry that needs reliable cutting tools, this article is for you.

什么是碳化钨?

Tungsten carbide is a material made by combining tungsten (W) and carbon (C). It is extremely hard—much harder than steel—and keeps its shape even under high pressure and heat.

Tools made from tungsten carbide last longer and cut more precisely than regular steel tools. They are also resistant to wear, heat, and breakage.

You can learn more about this material in our Carbide Tools Technical Glossary.

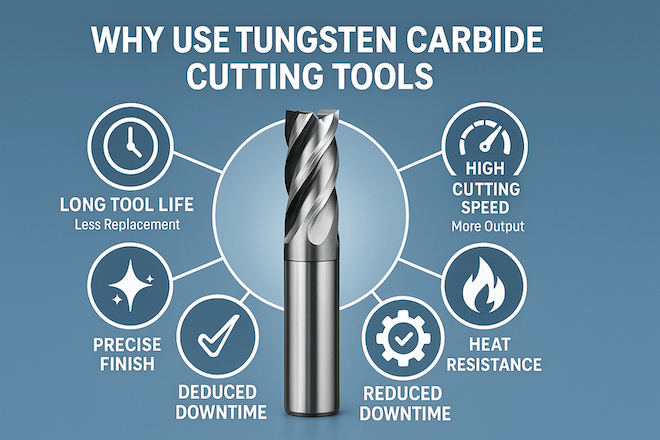

Why Use Tungsten Carbide Cutting Tools?

Here are the key benefits of tungsten carbide cutting tools:

Long tool life

High cutting speed

Precise finish

减少停机时间

降低维护成本

Work well on hard materials

Because of these benefits, carbide tools are used in many industries around the world.

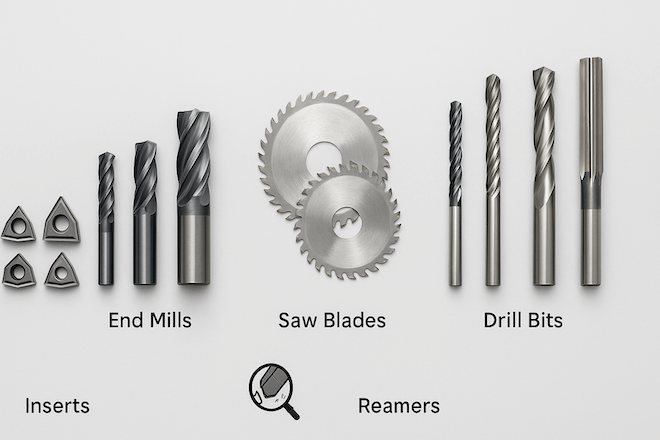

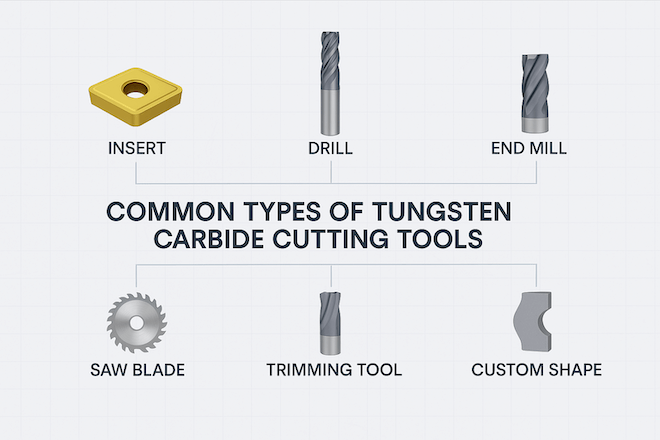

Common Types of Tungsten Carbide Cutting Tools

Below is a list of the most common types of tungsten carbide cutting tools, their shapes, and their uses:

1. Carbide Inserts

Carbide inserts are small cutting pieces used in turning, milling, and drilling tools. They are replaceable, which makes them cost-effective.

Shape: Triangle, square, diamond

Use: CNC lathes, turning, facing, grooving

Benefits: Easy to change, strong, high-speed cutting

👉 See our full line of 硬质合金刀片 on www.retopz.com

2. Carbide End Mills

Carbide end mills are used in milling machines to remove material from a workpiece. They come in different flute designs depending on the application.

Use: Slotting, contouring, plunging

Flutes: 2, 4, or more for different materials

Benefits: Sharp edges, smooth cuts, long life

👉 Check our carbide end mills collection for various styles and sizes.

3. Carbide Drills

These tools are used to drill holes in tough materials like steel, cast iron, and titanium. They maintain sharpness for a long time.

Use: Precision drilling, deep hole cutting

Benefits: High-speed operation, wear resistance

Find more about our tungsten carbide drills on www.retopz.com.

4. Carbide Saw Blades

Used for cutting wood, plastic, or metal. The carbide tips on the blade stay sharp for a long time.

👉 Browse our carbide saw blades for more details.

5. Carbide Trimming Tools

Carbide trimming tools are used in the can making industry and other precision cutting applications.

Use: Edge trimming, shaping

Benefits: Consistent cut quality, sharp edges

👉 Learn more about carbide trimming tools here.

6. Custom Carbide Tools

If your cutting needs are unique, you can design a custom shape or tool type for your process.

Use: Special shapes for non-standard jobs

Benefits: Perfect fit, better performance

👉 Work with us to design your custom carbide cutting tools.

7. Carbide Tips

Carbide tips are brazed onto other tools like cutters, turning tools, or chisels.

Use: Metal and wood cutting

Benefits: Easy to replace, hard wearing

👉 See carbide tips on www.retopz.com.

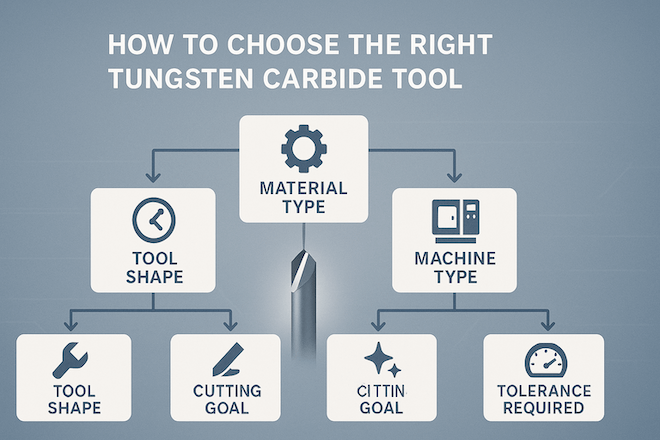

How to Choose the Right Tungsten Carbide Tool

Here are a few things to think about when choosing a 硬质合金切削刀具:

Material you are cutting:

Steel, aluminum, wood, plastic, etc.Tool shape:

Inserts, 立铣刀, drills, etc.Type of machine:

Manual or CNC, low-speed or high-speedCutting goal:

Rough cutting, finishing, grooving, drillingTolerance and accuracy needs

Need help choosing? Contact our team at 雷托普 for technical support.

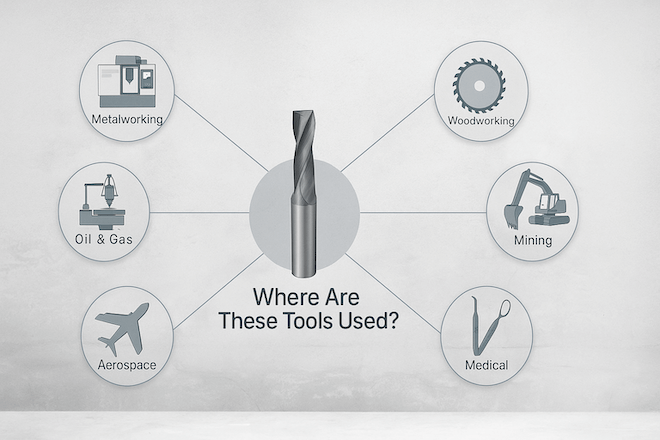

Where Are These Tools Used?

Tungsten carbide cutting tools are widely used in:

| 行业 | Use Cases |

|---|---|

| 金工 | CNC turning, milling, facing |

| 木工 | Cutting boards, trimming edges |

| 石油和天然气 | Drilling, valve components |

| 航天 | Machining titanium or carbon fiber |

| 汽车 | Cutting engine parts, gear machining |

| 模具 | Forming and shaping molds |

| 医疗设备 | Cutting stainless steel for tools |

Explore more use cases in our industry application pages.

为什么选择 Retop?

At Retop, we’ve spent over 14 years making high-performance carbide cutting tools for more than 50 countries. Here’s why customers trust us:

High-quality raw materials

Precision engineering

Custom tool design services

Strict quality control

Competitive pricing

Fast international delivery

👉 访问 www.retopz.com to see our full product range and get a free quote.

结论

Tungsten carbide cutting tools are strong, long-lasting, and ideal for precision cutting. Whether you need inserts, drills, end mills, or custom tools, the right choice can improve your productivity and reduce your costs.

We hope this guide helps you better understand the different types of carbide tools and how to choose the best one for your needs.