The use of 碳化钨耐磨件 is critical in many industries such as 矿业, 石油和天然气, 金属成型和制造业。

Known for its 硬度, 韧性, and long life, tungsten carbide is often chosen when steel or other alloys cannot handle the extreme stress of cutting, grinding, or wear.

At the same time, additive manufacturing (AM), also known as 3D printing, is transforming how companies design and produce metal and composite parts.

When we combine tungsten carbide with additive manufacturing, a new chapter in industrial production begins. The question is: What is the future of this combination?

In this article, we explore the current technologies, benefits, challenges, and potential future directions of using 3D printing for tungsten carbide wear parts.

Understanding Additive Manufacturing

Additive manufacturing is a process of creating a part layer by layer from digital models.

Unlike traditional machining, which cuts away material, AM builds up the part using powders, wires, or resins.

For metals and ceramics, technologies such as Selective Laser Melting (SLM), Binder Jetting, and Cold Spray are often used.

For decision-makers in industries that rely on wear parts, additive manufacturing offers the possibility of:

Complex shapes that cannot be made by traditional pressing and sintering.

Customization for specific machines and applications.

Faster prototyping and shorter supply chains.

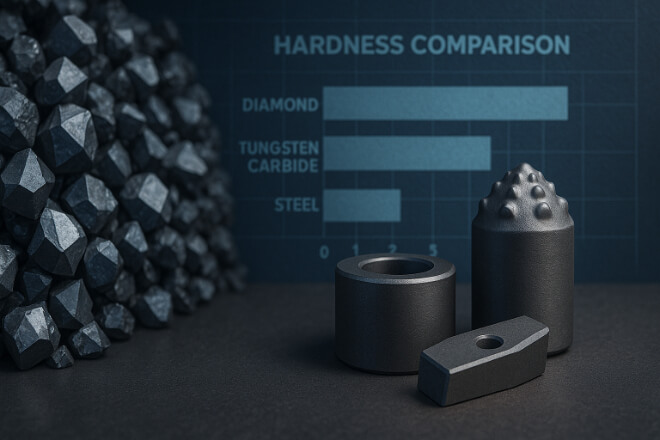

Why Tungsten Carbide Matters

Tungsten carbide (WC) is one of the hardest materials used in industry. It combines tungsten with carbon to create a compound with:

高的 硬度 (close to diamond).

Good toughness compared to ceramics.

Excellent wear and abrasion resistance.

Resistance to high temperatures.

Traditionally, tungsten carbide wear parts are made by powder metallurgy: pressing powders into shape and then sintering them at high temperature.

While this method is reliable, it limits design freedom. That is why companies are now looking at AM with tungsten carbide as a way to expand possibilities.

Current Methods of Printing Tungsten Carbide

At present, several additive manufacturing methods are being tested and applied to tungsten carbide:

1). Binder Jetting

WC powders are bound with a polymer binder.

The “green part” is then sintered.

Advantage: Good for complex shapes and large batches.

2). Selective Laser Melting (SLM)

A high-powered laser melts WC powders layer by layer.

Challenge: Tungsten carbide has high melting point and risk of cracks.

3). Cold Spray

WC powders are sprayed at high velocity onto a substrate.

Advantage: No melting, so less cracking.

Often used for coatings and repair.

4). Hybrid AM

Combines AM with traditional pressing, sintering, or infiltration.

Example: Printing a shape and then filling with cobalt binder.

Benefits of AM Tungsten Carbide

For decision-makers in manufacturing, the potential benefits of combining AM and tungsten carbide are clear:

Design freedom: Intricate internal channels for coolant, lightweight structures, or custom geometries.

Customization: Wear parts designed for unique machines or specific operating conditions.

Faster turnaround: Spare parts can be printed on demand, reducing downtime.

Material efficiency: Less waste compared to traditional machining of blanks.

Repair and refurbishment: Damaged parts can be rebuilt with AM instead of replaced.

Challenges and Limitations

Despite the promise, there are still many challenges:

Material processing issues: Tungsten carbide is brittle and can crack during printing or cooling.

High cost: AM systems capable of handling WC are expensive.

Consistency and standards: Parts need to meet strict tolerance and quality standards.

Scale: Printing large parts is still slow compared to pressing and sintering.

Binder concerns: Controlling the binder content is key to avoiding porosity or weak spots.

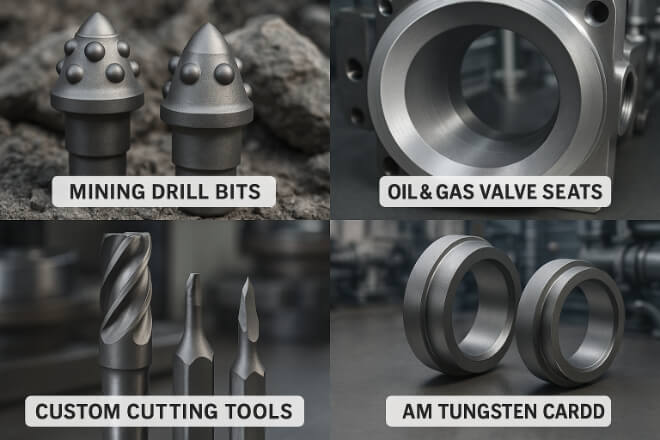

Applications Emerging Today

Some industries are already testing AM tungsten carbide in real applications:

Future Outlook

The future of AM with tungsten carbide looks promising but will depend on solving processing challenges. Likely trends include:

Better hybrid methods that mix AM with sintering and infiltration.

Improved powders specifically designed for AM.

Standardization so industries can trust AM parts for critical applications.

On-site manufacturing: In the future, mining or oil companies may print their own wear parts directly at the site.

Sustainability: AM allows for less material waste, aligning with global goals for cleaner production.

决策者的关键要点

For leaders in 矿业, 石油和天然气, 金属成型, and manufacturing, the message is clear:

Additive manufacturing of tungsten carbide is not science fiction—it is already happening.

The technology brings new opportunities in design freedom, repair, and efficiency.

However, challenges in cost, material control, and quality standards remain.

Companies should start exploring pilot projects and partnerships to stay ahead.

结论

Additive manufacturing and tungsten carbide represent a powerful combination.

As technology advances, it will become easier to produce customized, high-performance wear parts that outperform traditional designs.

The future will likely include more on-demand production, hybrid methods, and sustainable solutions.

For decision-makers, the key question is not if AM will impact tungsten carbide wear parts, but when and how fast your industry should adopt it.

如果您想了解任何公司的更多详细信息,请随时 联系我们.