Tungsten carbide tips are designed to handle extreme wear, impact, and heat. However, many performance problems do not come from the material itself, but from incorrect installation.

Even small mistakes during installation can lead to early failure, reduced efficiency, and higher operating costs.

This article explains the most common installation mistakes and shows how to avoid them in real industrial use.

Why Installation Quality Matters for Tungsten Carbide Tips

Tungsten carbide tips are strong, but they are not forgiving. Poor installation can create hidden stress, uneven load, or thermal problems that shorten tool life.

When a tip fails early, it often looks like a material issue. In reality, the root cause is usually incorrect alignment, wrong bonding method, or improper handling during installation.

For decision-makers, understanding these risks helps reduce downtime and replacement costs.

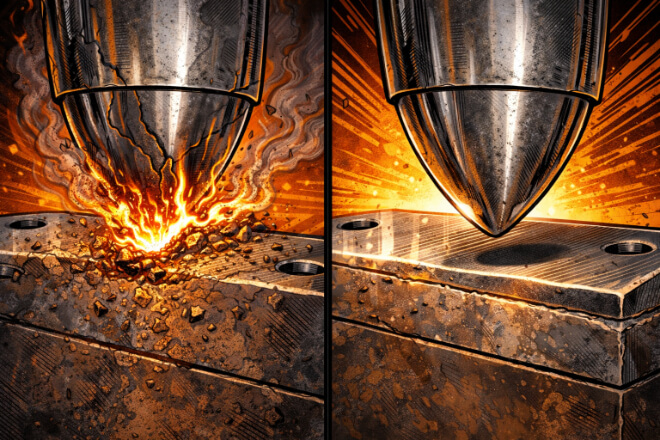

Mistake 1 – Poor Surface Preparation

One of the most common mistakes is installing tungsten carbide tips on dirty or poorly prepared surfaces.

Oil, dust, rust, or old adhesive residues prevent proper bonding and seating. This leads to micro-movement during operation, which increases stress and wear.

How to avoid it:

Clean the mounting surface thoroughly

Remove old adhesive completely

Ensure the surface is flat and undamaged

Use solvents suitable for industrial bonding

Proper surface preparation creates a stable base and improves long-term performance.

Mistake 2 – Incorrect Alignment During Installation

Misalignment is a silent killer for tungsten carbide tips. Even a small alignment error can cause uneven load distribution.

1). This often leads to:

Chipping at the edge

One-sided wear

Vibration and noise

Sudden tip breakage

2). How to avoid it:

Use alignment fixtures or jigs

Check concentricity before final fixing

Verify alignment after bonding or press-fitting

Avoid manual “eye-based” positioning

Correct alignment ensures the tip carries load evenly and lasts much longer.

Mistake 3 – Using the Wrong Bonding or Fixing Method

Not all tungsten carbide tips should be installed the same way. Using the wrong bonding method is a common and costly mistake.

Some applications require brazing, others require adhesive bonding, and some use mechanical fixing. Choosing incorrectly can lead to thermal cracks or weak joints.

1). Common bonding mistakes include:

Adhesive not rated for high temperature

Incorrect brazing temperature

Uneven adhesive thickness

Insufficient curing time

2). How to avoid it:

Match bonding method to operating conditions

Follow adhesive or brazing specifications

Control temperature carefully

Allow full curing before operation

Mistake 4 – Applying Excessive Force or Pressure

Tungsten carbide is extremely hard, but it is also brittle. Applying too much force during installation can cause internal micro-cracks that are not visible at first.

These cracks often grow during operation and lead to sudden failure.

1). Typical causes include:

Over-tightening bolts

Excessive press-fit force

Hammering during positioning

2). How to avoid it:

Follow recommended torque values

Use controlled press-fit tools

Never strike the tip directly

Apply force slowly and evenly

Gentle, controlled installation protects the internal structure of the carbide.

Mistake 5 – Ignoring Thermal Effects During Installation

Temperature changes during installation are often overlooked. Heating or cooling too quickly can introduce thermal stress between the carbide tip and its base material.

This is especially risky when materials have different thermal expansion rates.

1). How to avoid it:

Heat gradually when brazing

Avoid sudden cooling

Use compatible base materials

Allow natural temperature equalization

Managing temperature reduces internal stress and prevents cracking.

Mistake 6 – Skipping Final Inspection and Testing

Many failures happen because tools are put into service without proper inspection.

Small installation errors can be detected early if checked correctly.

Final checks should include:

Visual inspection for gaps or cracks

Stability test by light movement

Trial run under low load

Noise and vibration monitoring

Skipping this step often leads to expensive downtime later.

Best Practices Summary for Installing Tungsten Carbide Tips

The table below summarizes common mistakes and correct actions:

| Common Mistake | Resulting Problem | Correct Practice |

|---|---|---|

| Poor surface preparation | Weak bonding, early failure | Clean and inspect surfaces carefully |

| Misalignment | Uneven wear, vibration | Use alignment tools and fixtures |

| Wrong bonding method | Thermal cracks, weak joints | Match method to application |

| Excessive force | Hidden micro-cracks | Apply controlled, even pressure |

结论

Most tungsten carbide tip failures are not caused by material defects, but by avoidable installation mistakes.

By improving surface preparation, alignment, bonding choice, and inspection, companies can significantly extend tool life and reduce operating costs. Proper installation is not a minor detail—it is a key factor in long-term performance.

如果你想了解任何公司的更多详情, 请随时联系我们.